Sleeper beam welded gas pipe repair technology

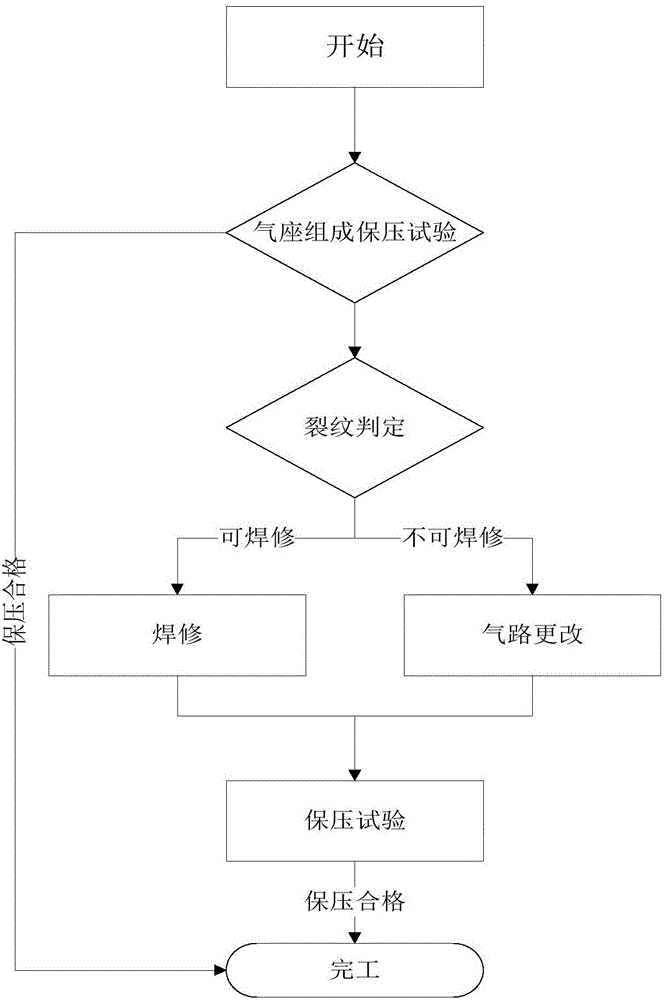

An air pipe and bolster technology is applied in the field of repairing the welded air pipe at the bolster of the PW-220 bogie of a railway passenger car, and can solve the problems of long maintenance cycle, difficulty in controlling the flatness of the air spring mounting seats on both sides of the bolster, and complicated procedures. , to achieve the effect of fast repair speed, low repair cost and simple repair process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

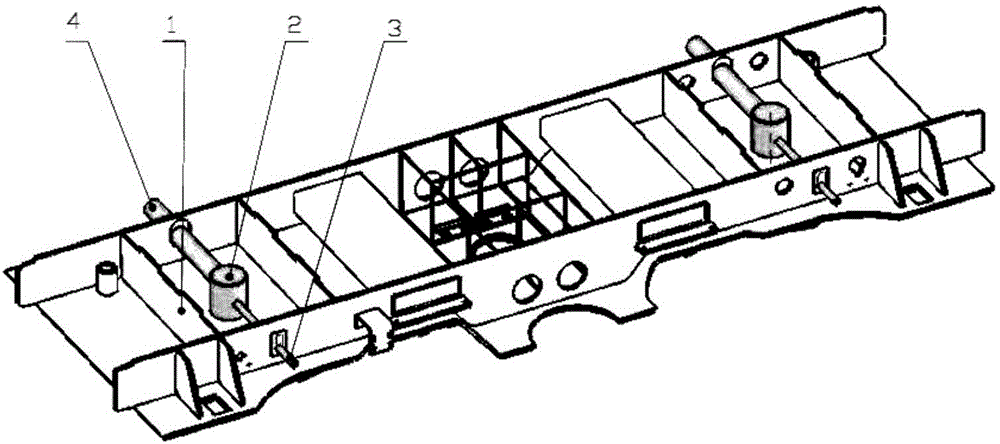

[0032] Such as figure 1 As shown, it is the repair process of bolster beam welding air pipe, which has two rod bodies 2 connected together by adjusting screw rod 1, and a J-shaped clamping device 3 arranged at the outer end of the rod body 2. In the slot, a screw hole is provided on the groove wall at the outer end of the slot, and a clamping screw 4 is screwed into the screw hole. The axis of the clamping screw 4 is collinear with the axis of the rod body 2 . In this embodiment, the adjusting screw 1 is a double-ended screw with opposite threads on both sides. The inner ends of the two rods 2 have threaded structures, and the adjusting screw 1 engages with the threaded structures of the rods 2. Rotating the adjusting screw can realize synchronous support or tensioning of the rods. .

[0033] Such as figure 2 As shown, it is a schematic diagram of the use state of the support beam of the present invention. When the side beam 5 of the frame 6 needs to be repaired, the devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com