Method capable of prolonging service life of fitter's tool

A technology for fitter tools and service life, which is applied in the field of extending the service life of fitter tools, can solve problems such as loss of hardness, shortened service life, and rise, and achieves the effects of reducing friction and heat generation, facilitating filing, and being easy to fall off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The method for prolonging the service life of a fitter's tool is characterized in that when using the fitter's tool for work, the two sides of the fitter's tool are used alternately.

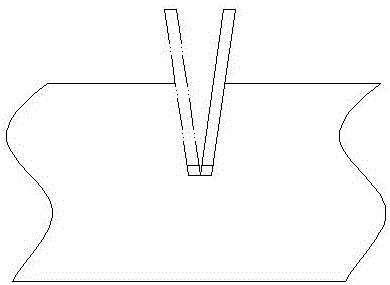

[0020] The fitter tool is a saw blade, which is sawed with one side of the saw blade, and the other side of the saw blade is not sawed, that is, the saw blade and the surface of the object to be sawed, so that the two sides of the saw blade are alternately performed, and the saw blade swings like a V during sawing. It is also called V-shaped sawing method.

[0021] Said sawing is full-tooth sawing.

[0022] The swing angle of the saw blade is 0.5 to 1°.

[0023] The fitter's tool is a file. When filing, use one side of the file to make 3 to 5 cuts, and then use the wrong side to make another 3 to 5 cuts. The two sides of the file work alternately.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com