Core expansion type positioning mandrel

A technology for positioning mandrels and hollow thin walls, which is applied in the direction of expanding mandrels, etc., can solve the problems of turning hollow thin-walled slender shafts, and the difficulty of processing and guaranteeing the grinding surface, so as to meet the requirements of guaranteed processing, novel structure, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

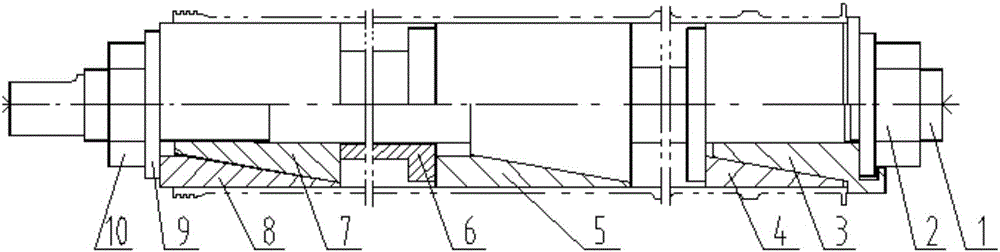

[0034] A core-expanding positioning mandrel, the core-expanding positioning mandrel is a 3-section core-expanding positioning mandrel, which is mainly used for machining the outer surface of a hollow thin-walled slender shaft, refer to figure 2 , the expansion-type positioning mandrel is nested in the hollow thin-walled elongated shaft, and the hollow thin-walled elongated shaft is taken as an example of a catheter in this embodiment.

[0035] refer to figure 2 , a center-expanding positioning mandrel includes a shaft 1, through which the front-end nut 2, the pressure ring 3, the front-end elastic member 4, the middle elastic member 5, the pressure sleeve 6, the tapered block 7, The rear end elastic member 8, the gland 9 and the rear end nut 10; the shaft 1 is a revolving body composed of multiple cylindrical segments, and both ends of the shaft 1 are provided with central holes for connecting with the machine tool.

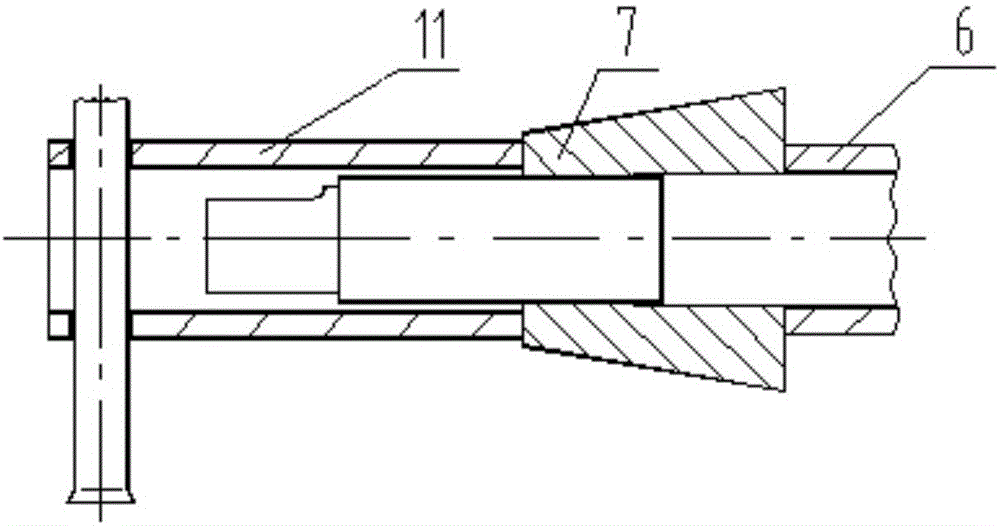

[0036] refer to Figure 4 , the shaft 1 is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com