An electric balance adjustment device for a bending machine

An electric balance and adjustment device technology, applied in the field of bending machines, can solve the problems of complicated operation, time-consuming and laborious, poor adjustment accuracy, etc., and achieve the effects of high adjustment accuracy, high efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

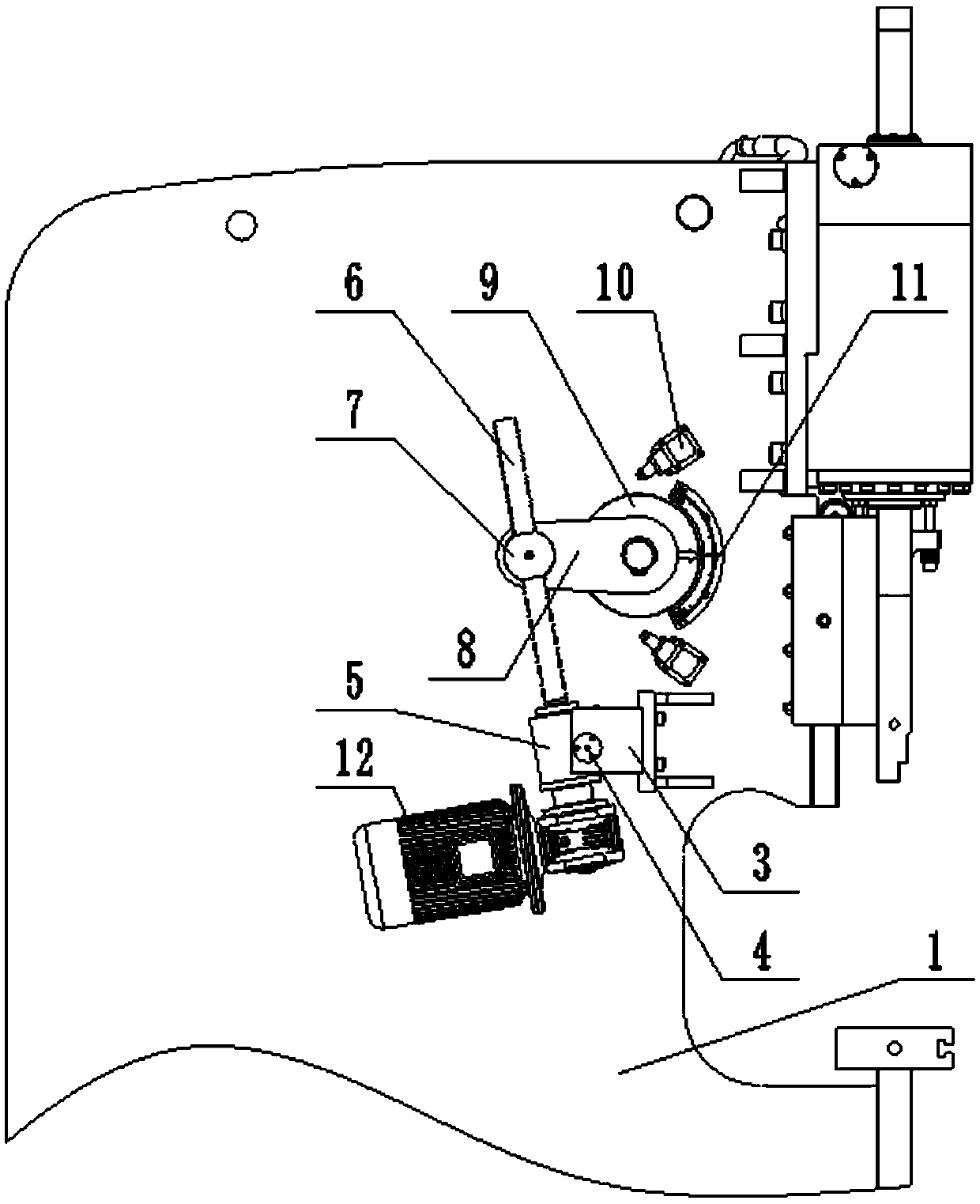

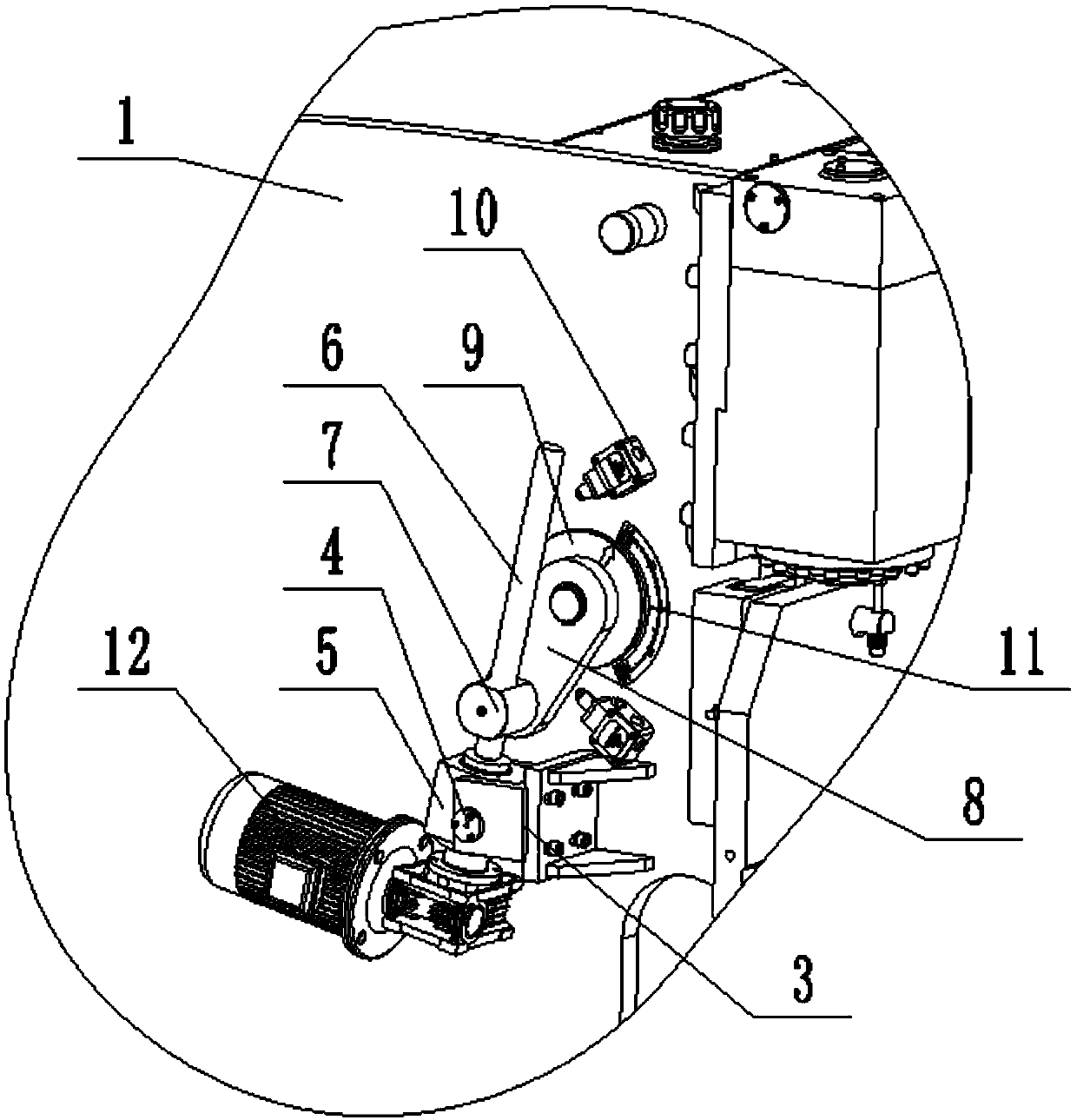

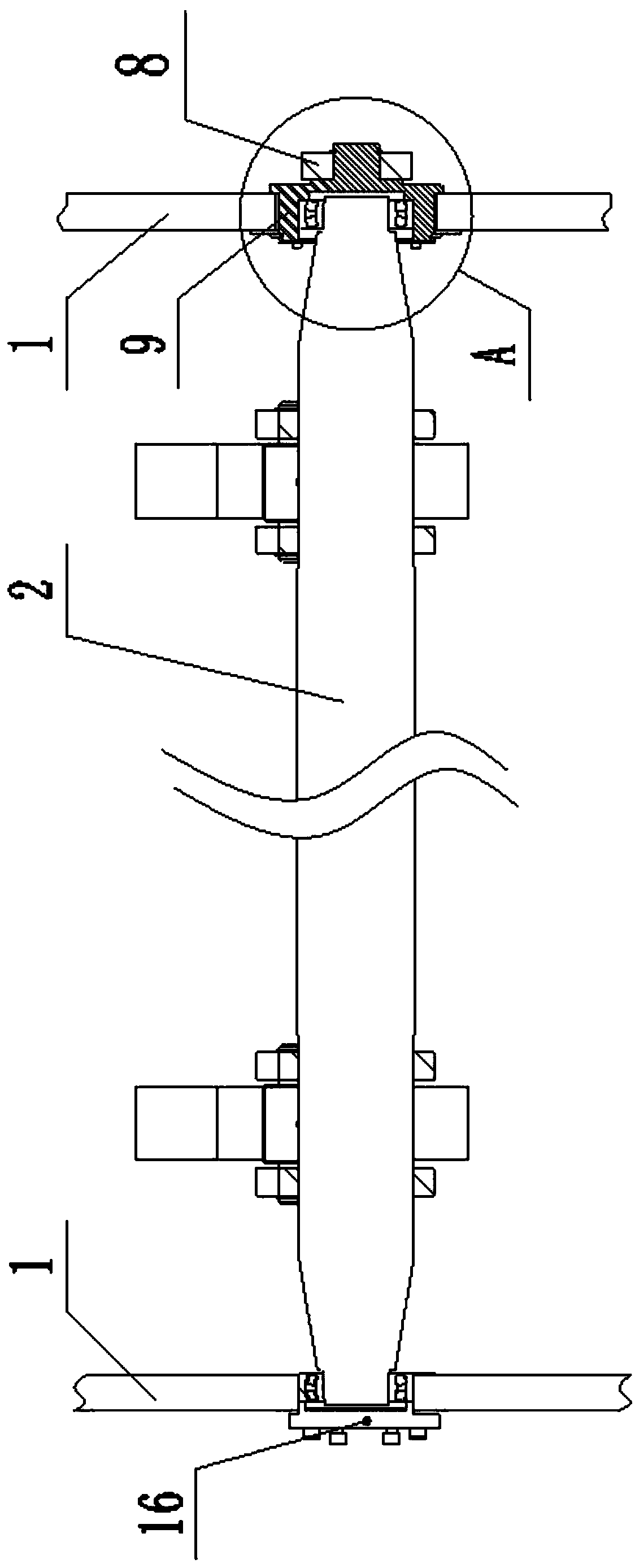

[0041] like Figure 1 to Figure 5 As shown, this embodiment provides an electric balance adjustment device for a bending machine, which includes two wall panels 1, a slider and a balance adjustment mechanism. A balance shaft 2 is arranged between the two wall panels 1, and the slider is arranged on two The front end of the wallboard 1 and the two ends of the balance shaft 2 are respectively provided with a rocking bar, and the two rocking bars are respectively connected with the two ends of the rear end face of the slide block. When the slide block moves up and down, the balance shaft 2 rotates synchronously.

[0042] The balance adjustment mechanism includes an adjustment seat 3, a bearing seat 5, a lead screw 6, a supporting plate 8, an eccentric sleeve 9 and a reduction motor 12, the adjustment seat 3 is installed on the outer surface of one of the wallboards 1, and the bearing seat 5 passes through the The pin shaft 4 is connected with the adjustment seat 3; the lead screw...

Embodiment 2

[0047] This embodiment provides a method for adjusting the parallelism of the slider of the bending machine. The electric balance adjustment device of the bending machine in Embodiment 1 is used for adjustment. The specific steps are as follows:

[0048] ①Assemble the equipment according to the structure in Example 1, and the assembly steps are as follows:

[0049] First place the balance shaft 2 obliquely between the two wall panels 1, then insert one end of it into the installation hole of the wall panel 1, and protrude from the inside of the wall panel 1 to the outside of the wall panel 1, and then insert the balance shaft 2 Insert the other end into the installation hole of another wall panel 1; then lift the balance shaft 2 with a crane, align the axis of the balance shaft 2 with the center of the installation hole on the wall panel 1, and knock the self-aligning roller bearing into the uninstalled balance adjustment Insert the end of the balance shaft 2 into the inner ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com