Electronic element work unit and work equipment using electronic element work unit

A technology for electronic components and components, applied in the field of electronic component operation units, can solve the problems of consuming refrigeration energy costs, performing cold testing operations, and unable to maintain pre-cooling temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

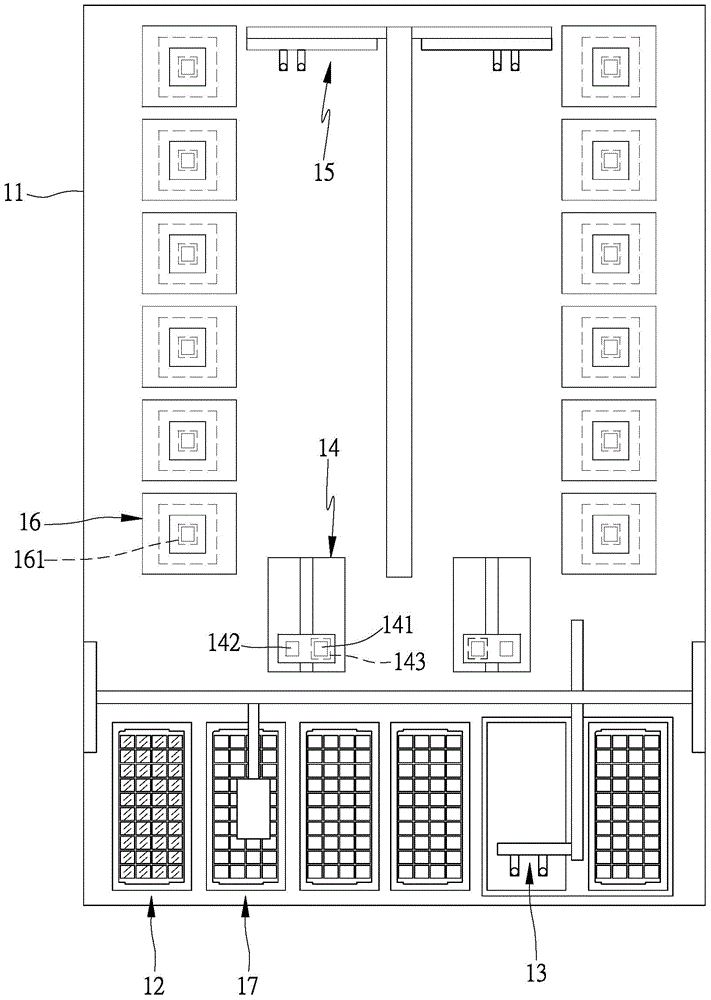

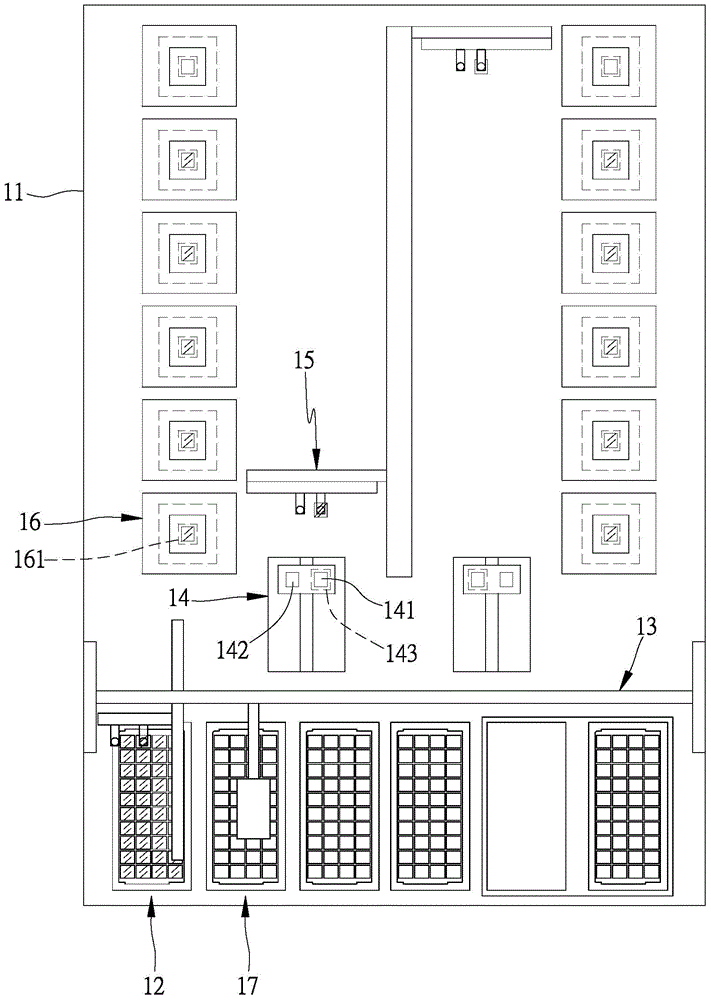

[0045] In order to make your examiner further understand the present invention, hereby give a preferred embodiment and cooperate with the drawings, as follows in detail:

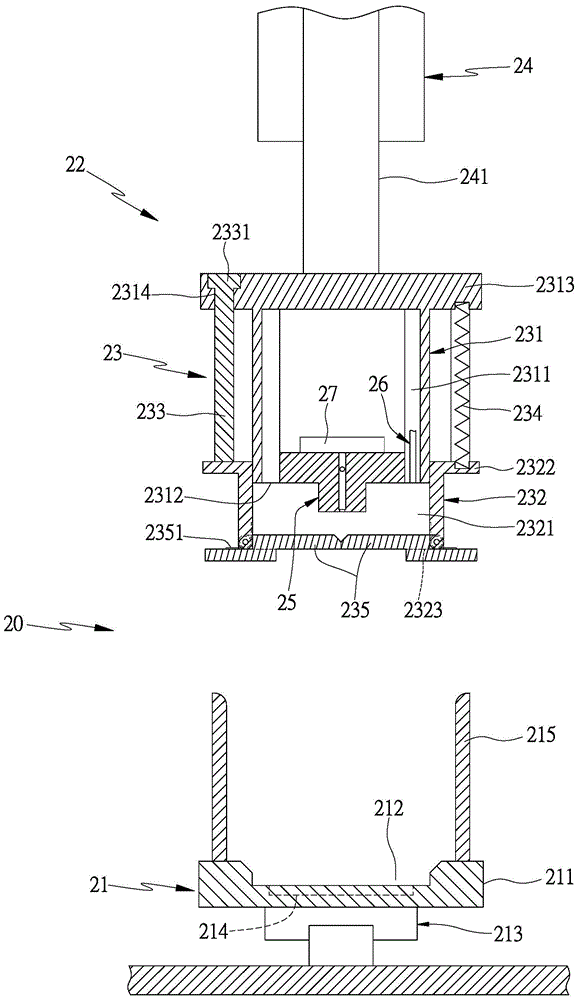

[0046] see image 3 The working unit 20 of the present invention includes a first holder 21 and a pick-up mechanism 22. The first holder 21 is provided with at least one holder for holding electronic components to be operated. The holder can be a carrier platform, material tray or test seat, etc., further, at least one first preheating member can be provided on the bearing member to precool or preheat the electronic components to be operated. In this embodiment, the first The holder 21 is provided with a first holder 211 which is a carrier, and the first holder 211 is provided with a first holder trough 212 to accommodate the electronic components to be operated. The conveying member 213 below the 211 is used to drive the first bearing member 211 to move in at least one direction (such as the first directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com