Modified Y catalyst containing rare earth and phosphorus

A catalyst and modification technology, applied in the direction of molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of no obvious improvement in the pore structure of cracking catalysts, shortened catalyst preparation process, and poor thermal and hydrothermal stability. Poor and other problems, to achieve the effect of ensuring the continuity of the skeleton, low production cost, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

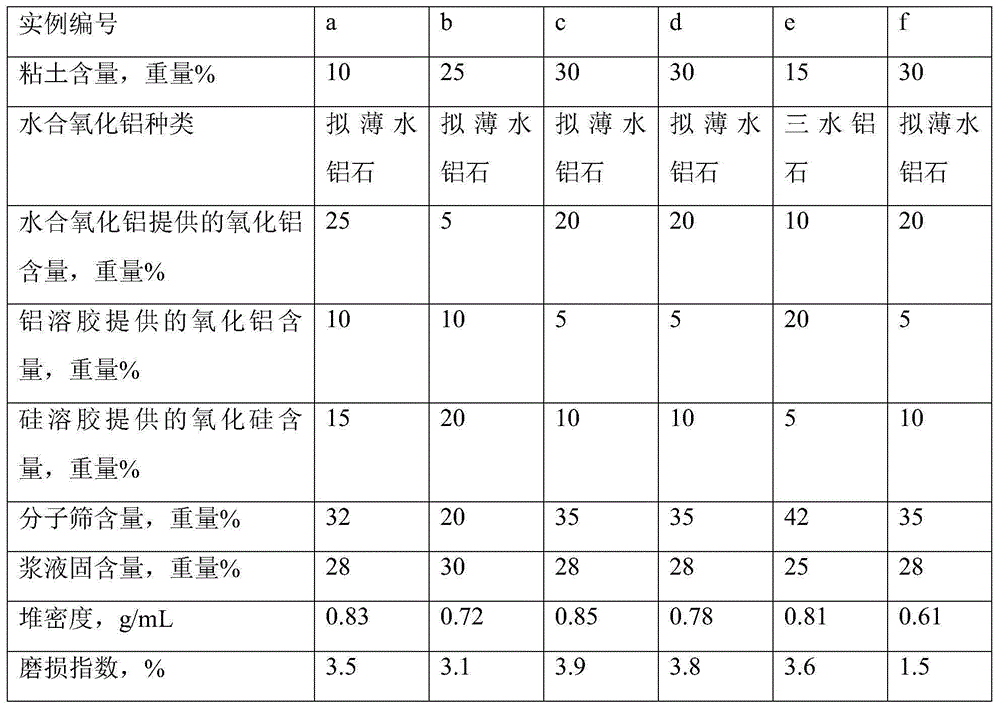

Examples

Embodiment 1

[0043] This example is to prepare the raw material fine-grained NaY molecular sieve.

[0044] 335.69g high alkali sodium metaaluminate solution (provided by Sinopec Catalyst Changling Branch, Al 2 o 3 The content is 40.2g / L, Na 2 O content is 270g / L, specific gravity is 1.323) joins 466.18g water glass (Sinopec Catalyst Changling Branch provides, SiO 2 The content is 260.6g / L, Na 2 The O content is 81.6g / L, the specific gravity is 1.2655, and the modulus is 3.3), aged with stirring at 20°C for 24 hours, then statically aged at 30°C for 48 hours, and finally added 104g to ionized water. The resulting directing agent has a final molar ratio of 16Na 2 O: A1 2 o 3 :16SiO2 2 :290H 2 O, the prepared directing agents were all used in the preparation of the following reaction mixture. The addition amount of the directing agent is calculated according to the fact that the moles of aluminum elements in the directing agent account for 20% of the total moles of aluminum elements...

Embodiment 2

[0048] Firstly, ammonium exchange is carried out on the raw material fine-grained NaY molecular sieve A. Prepare 10 liters of 0.5 mol / L ammonium nitrate aqueous solution. Weigh 1000 grams of fine-grained NaY molecular sieve, dissolve it in 10 liters of prepared ammonium nitrate aqueous solution, stir at a constant temperature of 90°C for 1 hour at a stirring speed of 300 rpm, and then filter the molecular sieve. Repeat the above operation until the NaY in the molecular sieve 2 The O content reaches 2.5-5wt%. The dried sample was subjected to hydrothermal treatment for 1.5 h at 500° C. and 100% water vapor gauge pressure of 0.1 MPa. Measure 1 liter of clean water and dissolve 200 grams of the above-mentioned sample in the clean water, heat up and stir rapidly, the temperature is 95° C., and the stirring speed is 300 rpm. Quickly add ammonium hexafluorosilicate aqueous solution to the molecular sieve slurry, add 50 grams of ammonium hexafluorosilicate in total, then stir at co...

Embodiment 3

[0050] First, ammonium exchange is carried out on the raw material fine-grained NaY molecular sieve B. The preparation concentration is 10 liters of 0.2mol / L ammonium sulfate aqueous solution. Weigh 1000 grams of fine-grained NaY molecular sieve, dissolve it in 10 liters of prepared ammonium nitrate aqueous solution, stir at a constant temperature of 90°C for 1 hour at a stirring speed of 300 rpm, and then filter the molecular sieve. Repeat the above operation until the NaY in the molecular sieve 2 The O content reaches 2.5-5wt%. The dried sample was subjected to hydrothermal treatment for 2.0 h at 570° C. and 100% water vapor gauge pressure of 0.2 MPa. Measure 1 liter of clean water and dissolve 300 g of the sample obtained in the above steps into the clean water, heat up and stir rapidly, the temperature is 80° C., and the stirring speed is 300 rpm. Quickly add ammonium hexafluorosilicate aqueous solution to the molecular sieve slurry, add 50 grams of ammonium hexafluorosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com