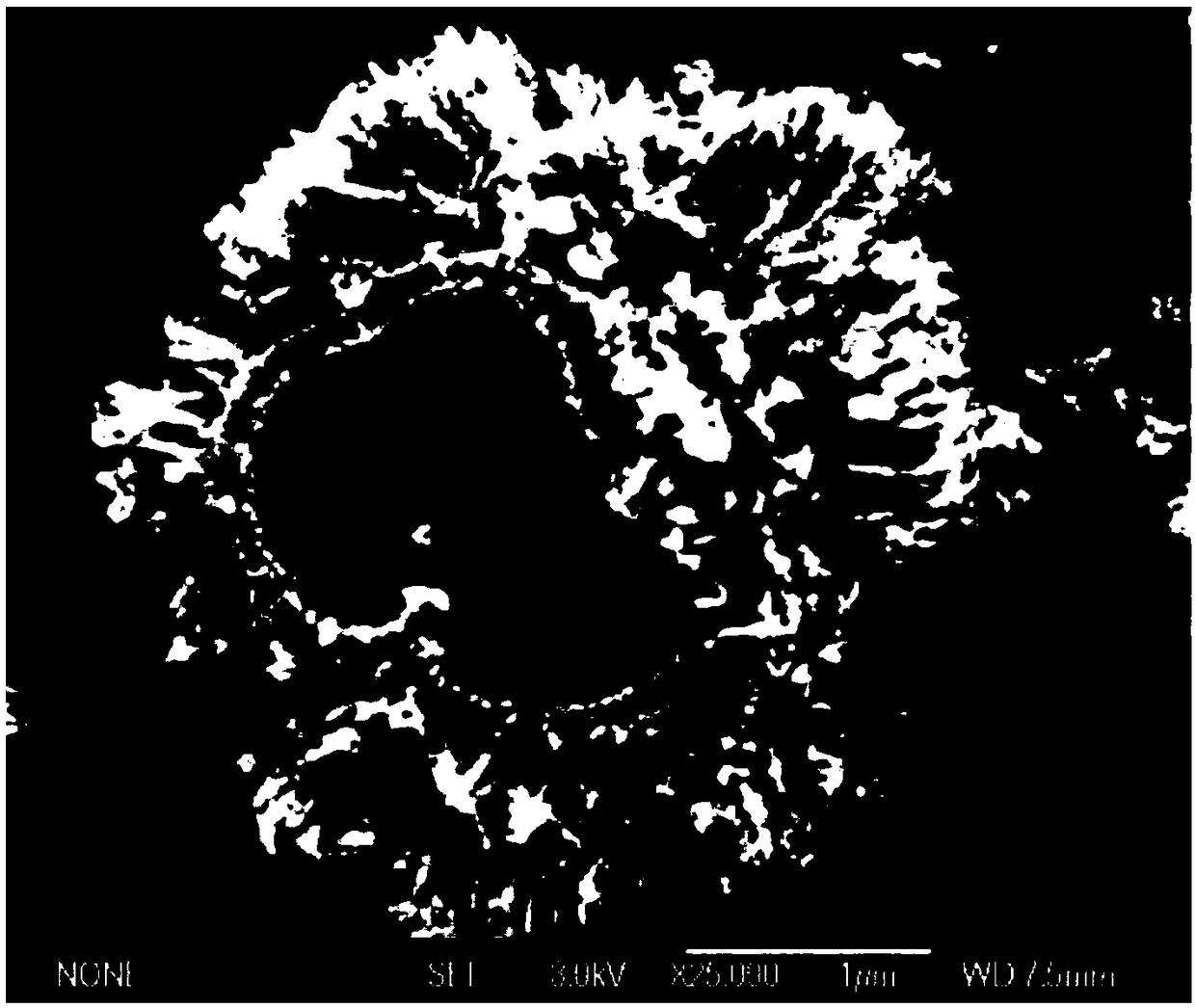

A preparation method for self-assembly of one-dimensional nanorods to form chestnut shell-like three-dimensional titanium dioxide hollow microspheres with hierarchical structure

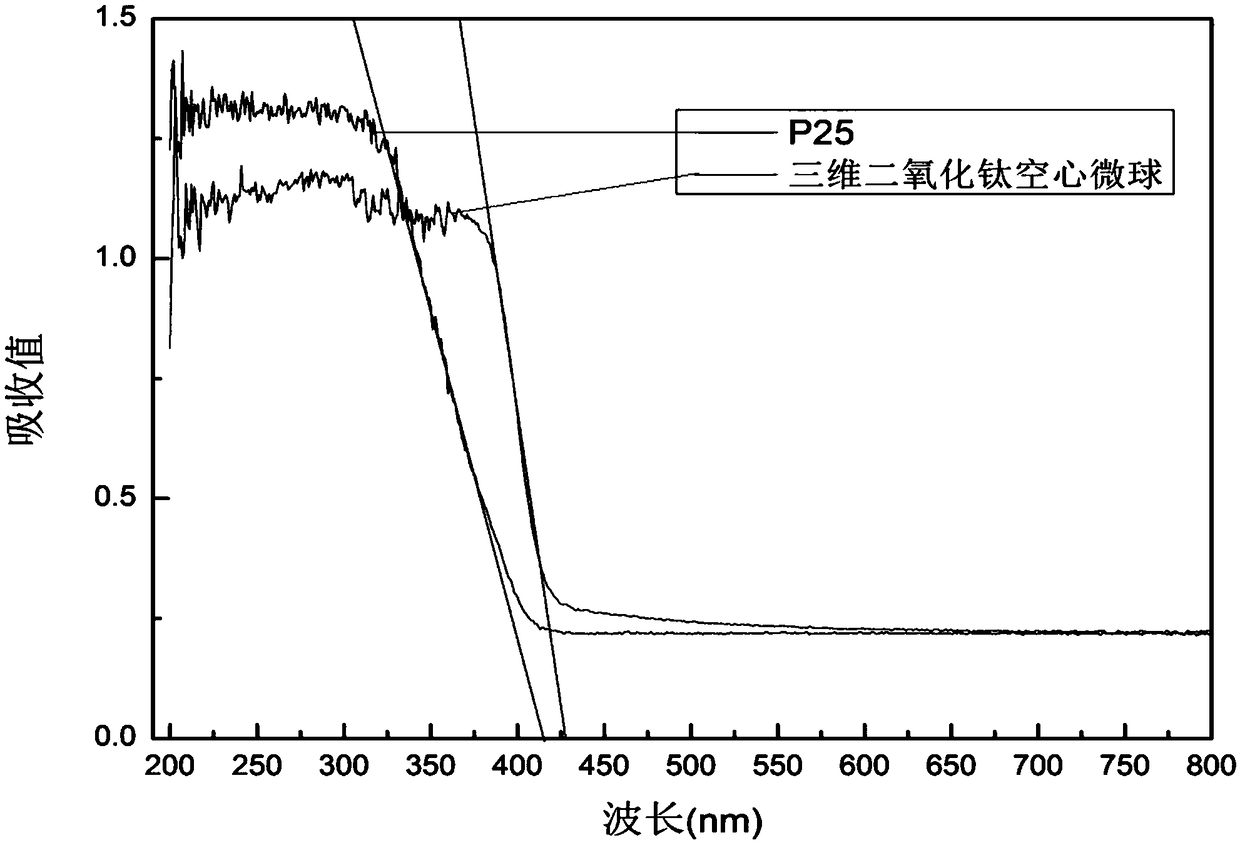

A hierarchical structure, titanium dioxide technology, applied in titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of complex preparation process, harsh operating conditions, unsuitable for industrialized large-scale production, etc. It is not easy to agglomerate, and the effect of enhancing the utilization rate of light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing chestnut-shell-shaped three-dimensional titanium dioxide hollow microspheres with a hierarchical structure formed by self-assembly of one-dimensional nanorods, comprising the following steps:

[0048] (1) Add n-butyl titanate to acetone at a stirring rate of 500 rpm to obtain solution A, the molar ratio of n-butyl titanate to acetone is 1:20;

[0049] (2) Add 37wt% concentrated hydrochloric acid to the above solution A at a stirring rate of 500 rpm, and continue stirring for 10 minutes to obtain solution B, the molar ratio of hydrochloric acid to titanium precursor is 5:1;

[0050] (3) Transfer solution B to a hydrothermal reactor, react at 150°C for 8 hours, and the filling ratio of the hydrothermal reactor is 60%;

[0051] (4) After the reaction is completed, the obtained solid is separated, washed three times with deionized water and ethanol, and dried at 80° C. for 12 hours;

[0052] (5) After the dried sample was calcined at 500° C. for 2 h,...

Embodiment 2

[0084] A method for preparing chestnut-shell-shaped three-dimensional titanium dioxide hollow microspheres with a hierarchical structure formed by self-assembly of one-dimensional nanorods, comprising the following steps:

[0085] (1) Add n-butyl titanate to acetone at a stirring rate of 1000 rpm to obtain solution A, and the molar ratio of n-butyl titanate to acetone is 1:20.

[0086] (2) At a stirring rate of 500 rpm, add 37 wt% concentrated hydrochloric acid to the above solution A, and continue stirring for 10 minutes to obtain solution B; the molar ratio of hydrochloric acid to titanium precursor is 5:1

[0087] (3) The solution B was transferred to a hydrothermal reactor, and reacted at 180° C. for 8 hours, and the filling ratio of the hydrothermal reactor was 70%.

[0088] (4) After the reaction, the obtained solid was separated, washed three times with deionized water and ethanol, and dried at 105° C. for 8 hours.

[0089] (5) After the dried sample was calcined at 40...

Embodiment 3

[0092] A method for preparing chestnut-shell-shaped three-dimensional titanium dioxide hollow microspheres with a hierarchical structure formed by self-assembly of one-dimensional nanorods, comprising the following steps:

[0093] (1) Add n-butyl titanate to acetone at a stirring rate of 1000 rpm to obtain solution A, the molar ratio of n-butyl titanate to acetone is 1:10;

[0094] (2) Add 37wt% concentrated hydrochloric acid to the above solution A at a stirring rate of 1000 rpm, and continue stirring for 10 minutes to obtain solution B, the molar ratio of hydrochloric acid to titanium precursor is 8:1;

[0095] (3) Transfer solution B to a hydrothermal reactor, react at 120°C for 24 hours, and the filling ratio of the hydrothermal reactor is 60%;

[0096] (4) After the reaction is completed, the obtained solid is separated, washed three times with deionized water and ethanol, and dried at 80° C. for 12 hours;

[0097] (5) After the dried sample was calcined at 400° C. for 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com