Use method of device for combined purification of organic waste gas

An organic waste gas, combined technology, applied in chemical instruments and methods, combustion methods, separation methods, etc., can solve the problems of increasing the complexity of the purification device system, increasing investment and operating costs, and unstable concentration, and achieves no production of two. Secondary pollution, convenient and quick use and maintenance, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

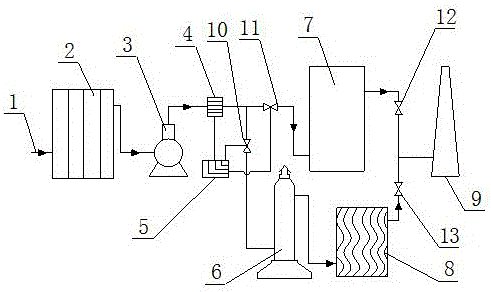

[0014] For specific examples, see figure 1 , a combined device for purifying organic waste gas, including intake pipe 1, filter 2, booster fan 3, concentration detector 4, valve controller 5, purification absorption tower 6, rotary airfoil regenerative burner 7, activated carbon 8 and an emptying tower 9, the filter 2 is provided with an inlet pipe 1, one end of the booster fan 3 is connected to the filter 2, and the other end of the booster fan 3 is connected to the concentration detector 4 Together, a valve two 11 is provided between the concentration detector 4 and the rotary airfoil regenerative burner 7, a valve two 10 is provided between the concentration detector 4 and the purification absorption tower 6, and the rotary airfoil A valve three 12 is arranged between the regenerative burner 7 and the emptying tower 9, and one end of the activated carbon 8 communicates with the purification absorption tower 6, and the other end of the activated carbon 8 communicates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com