Mussel byssus removing device

A small-diameter and screening technology, applied in slaughtering, bivalve processing, food science and other directions, can solve the problems of increasing labor force, unable to remove silk from sea rainbow, unable to liberate labor, etc., and achieve high practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below with reference to the drawings and embodiments.

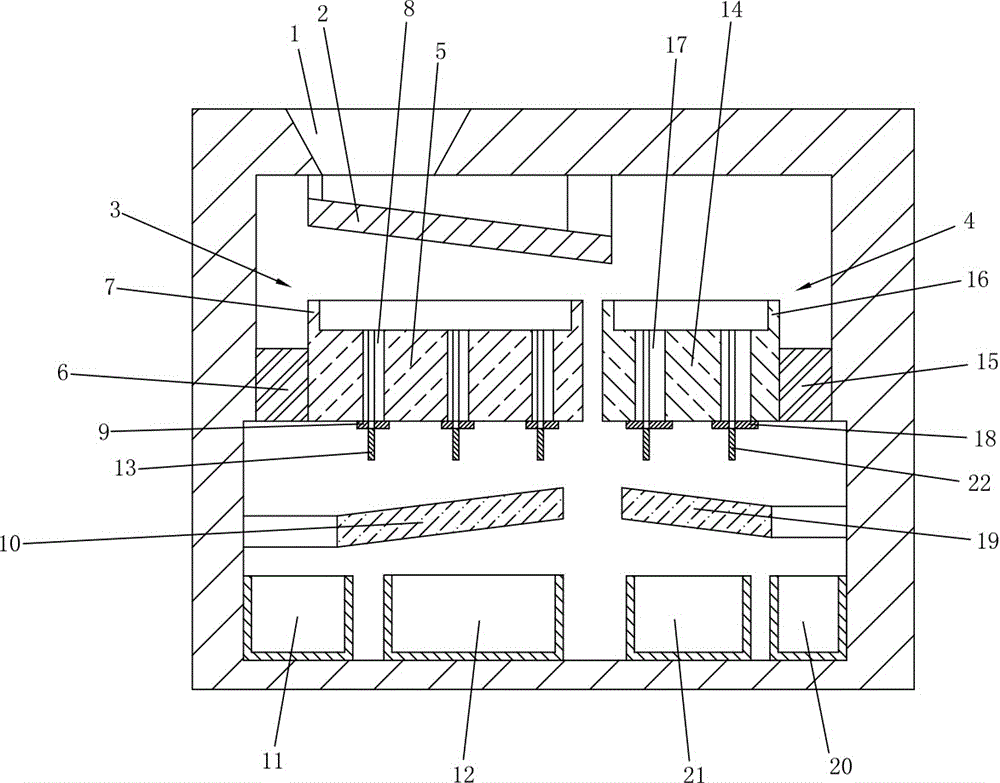

[0012] Please refer to figure 1 , the embodiment of the present invention includes:

[0013] A Haihong silk removing device, comprising a material inlet 1, a sub-screen 2 connected to the material inlet 1, the sub-screen 2 is arranged obliquely, the sub-screen 2 has two outlets, and two outlets They are located under the sub-sieve 2 and at the lower end of the sub-sieve 2 respectively, a small-diameter defilter 3 is arranged under the sub-sieve 2, and a large-diameter defilter is arranged next to the lower end of the sub-sieve 2. Silk device 4; Minor diameter silk remover 3 comprises the minor diameter one-level feeding disc 5 and the minor diameter one-level vibrating motor 6 that drives the minor diameter one-level feeding disc 5 vibrations, and the upper surface edge of the minor diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com