Fuel pump shell machining clamp

A fuel pump and housing technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of easy deformation of the workpiece, achieve the effect of simple and compact structure, and overcome unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

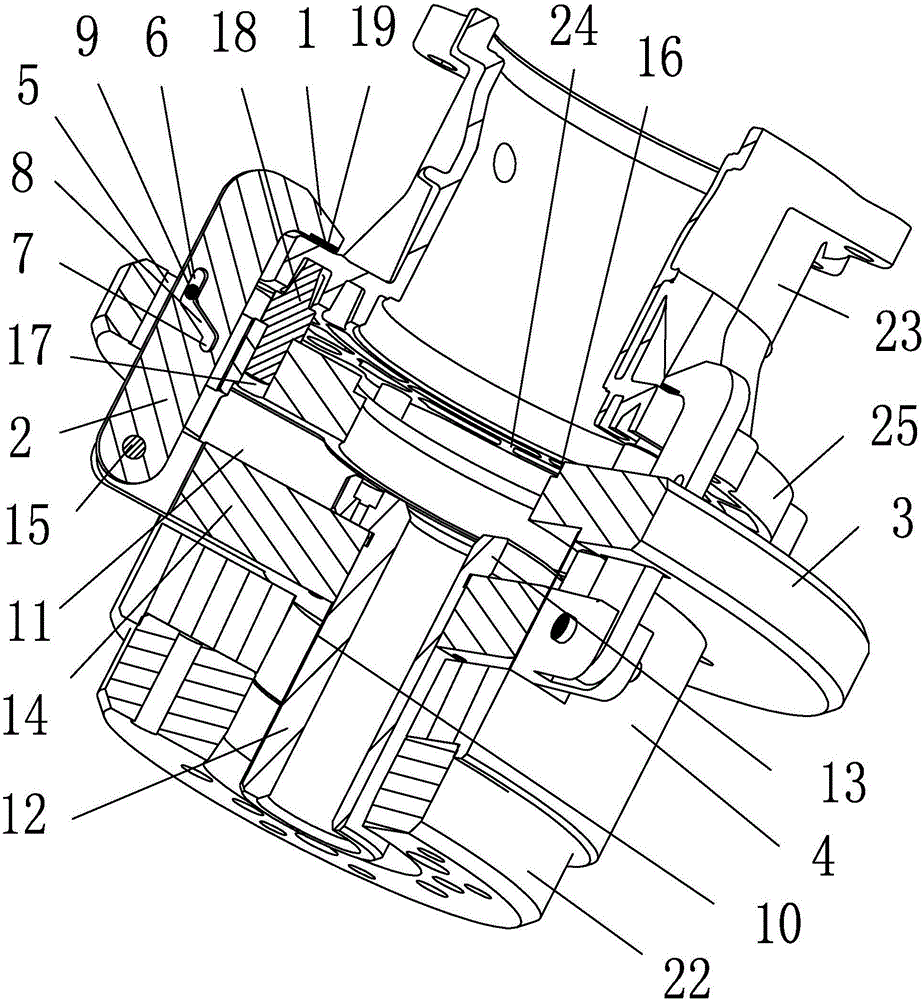

[0016] Embodiment 1, as attached figure 1 Shown: a fuel pump housing processing fixture, including: three pressure rods 2 with claw feet 1 at the front end, a positioning plate 3, a connecting column 4 screwed to the rear end of the positioning plate 3 at the front end, and a pressure rod driving device; Positioning plate 3 is provided with end through hole 5 that number is the same as 2 numbers of pressure rods and is evenly distributed along the circumference; Rod drive connection.

[0017] The cross-sectional shape of the end through hole 5 is a rectangle whose length direction is the radial direction of the positioning plate 3; the cross-sectional shape of the pressure rod 2 is a rectangle whose thickness matches the width of the end through hole 5; Guide through groove is arranged; Guide through groove comprises: outer groove 6, be positioned at the inner groove 7 of outer groove 6 rear side, inclined groove 8; One end of inclined groove 8 is communicated with the rear e...

Embodiment 2

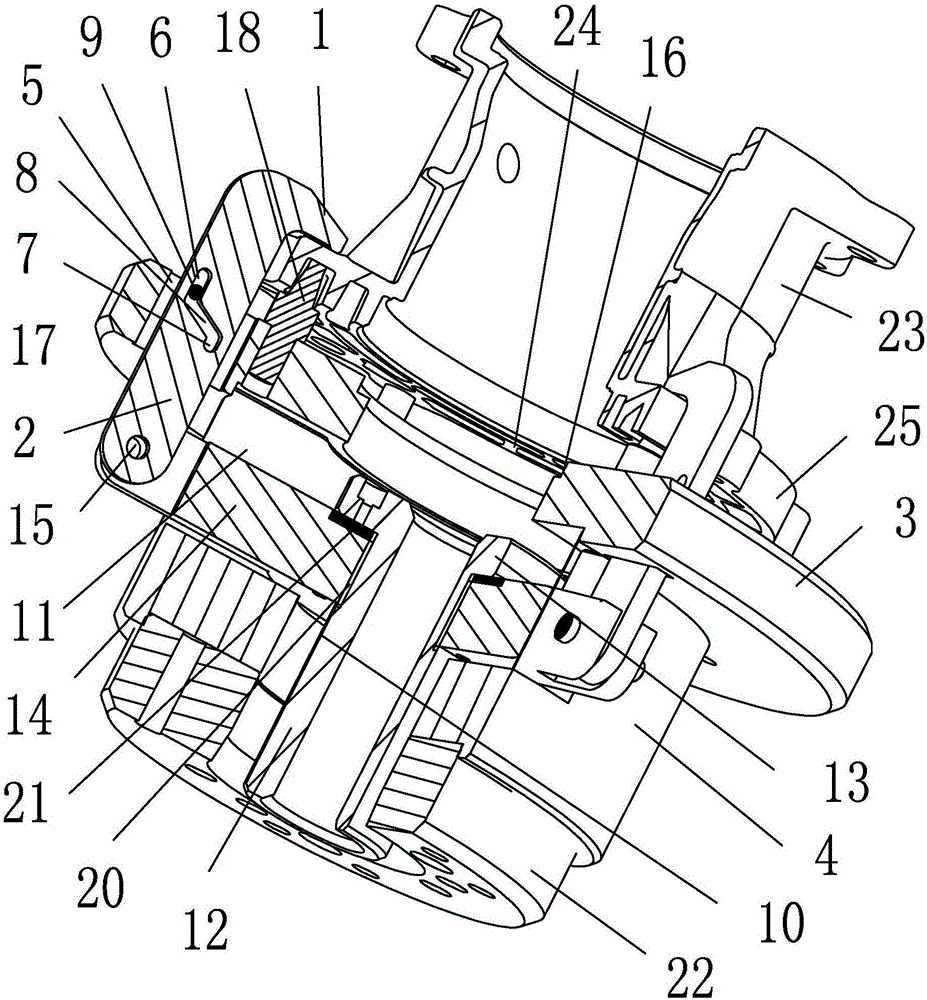

[0021] Embodiment 2, as attached figure 2 Shown: a fuel pump housing processing fixture, including: three pressure rods 2 with claw feet 1 at the front end, a positioning plate 3, a connecting column 4 screwed to the rear end of the positioning plate 3 at the front end, and a pressure rod driving device; Positioning plate 3 is provided with end through hole 5 that number is the same as 2 numbers of pressure rods and is evenly distributed along the circumference; Rod drive connection.

[0022] The cross-sectional shape of the end through hole 5 is a rectangle whose length direction is the radial direction of the positioning plate 3; the cross-sectional shape of the pressure rod 2 is a rectangle whose thickness matches the width of the end through hole 5; Guide through groove is arranged; Guide through groove comprises: outer groove 6, be positioned at the inner groove 7 of outer groove 6 rear side, inclined groove 8; One end of inclined groove 8 is communicated with the rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com