A detection method for three-phase power supply phase loss during motor operation and a motor phase loss protection system

A three-phase power supply and phase loss detection technology, applied in emergency protection circuit devices, electrical components, etc., can solve the problems of low reliability, high environmental requirements, and high production and maintenance costs of relay protection devices, so as to improve production efficiency. and economic benefits, low production or purchase costs, and reducing the effect of motor phase-deficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] A method for detecting phase loss of a three-phase power supply during motor operation proposed by an embodiment of the present invention will be described with reference to the accompanying drawings.

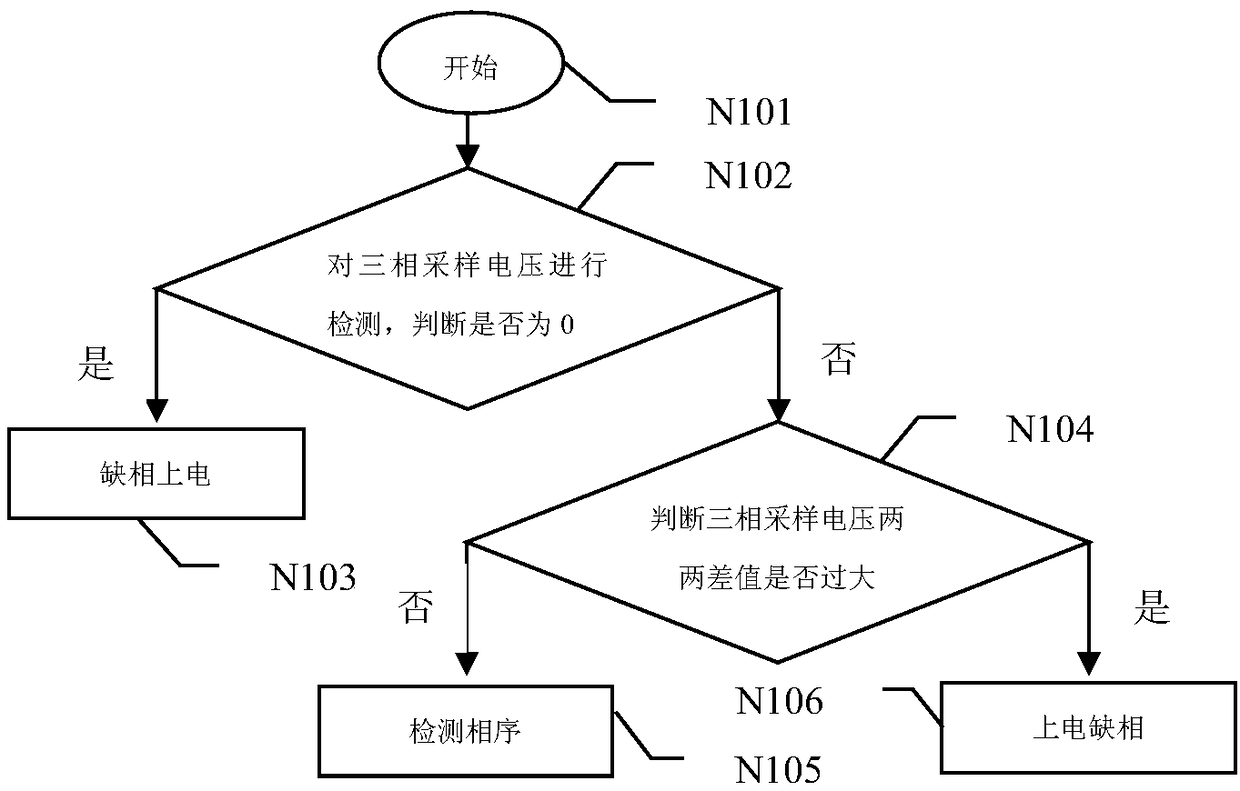

[0043] Such as figure 1 As shown, the three-phase power supply phase loss detection method during the operation of the motor includes the following steps:

[0044] N101, start, the motor runs;

[0045] N102, sampling and testing the three-phase voltage, and judging whether it is 0;

[0046] N103, if the voltage of any phase in the three-phase sampling voltage is 0, it is considered that the phase is missing and powered on;

[0047] N104, if the three-phase sampling voltages are not 0, then continue to judge whether the difference between the three-phase sampling voltages is too large;

[0048] N105, if not, perform phase sequence detection;

[0049] N106, if the difference is too large, it is considered to be power-on phase loss.

[0050] Specifically, the phase lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com