Gold nanopore thin film three-electrode ionizing sensor array having temperature compensation function

A sensor array and temperature compensation technology, which is applied in the field of gas sensing, can solve the problems of small collection current, large area, and low sensitivity, and achieve the effect of increasing sensitivity, increasing collector current, and eliminating the influence of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] In this example, according to image 3 , Figure 4 The shown gold nanoporous film three-electrode ionization sensor array with temperature compensation function, the sensor array is distributed side by side according to a plurality of gold nanoporous film three-electrode ionization sensors, and the first electrodes of all sensors are made on the same plate.

[0072] One sensor in the array is used to detect temperature, and the other sensor detects gas concentration. The cathodes of the two sensors are made on the same plate, the two extraction poles and the collector poles have the same structure, and the two sensors have different pole spacings. The intervals between the second electrode pads of two adjacent sensors and the third electrode pads of two adjacent sensors are both 5 mm. The pole spacing of the sensors in the array is set according to the diameter of the vent hole, the lead-out hole, the side length and the hole depth of the deep groove. One of the sens...

Embodiment 2

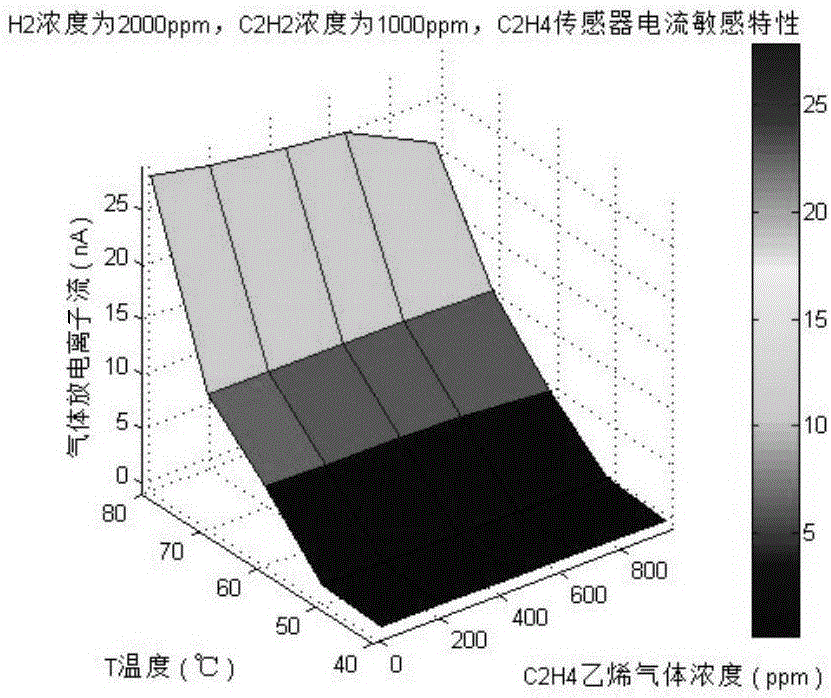

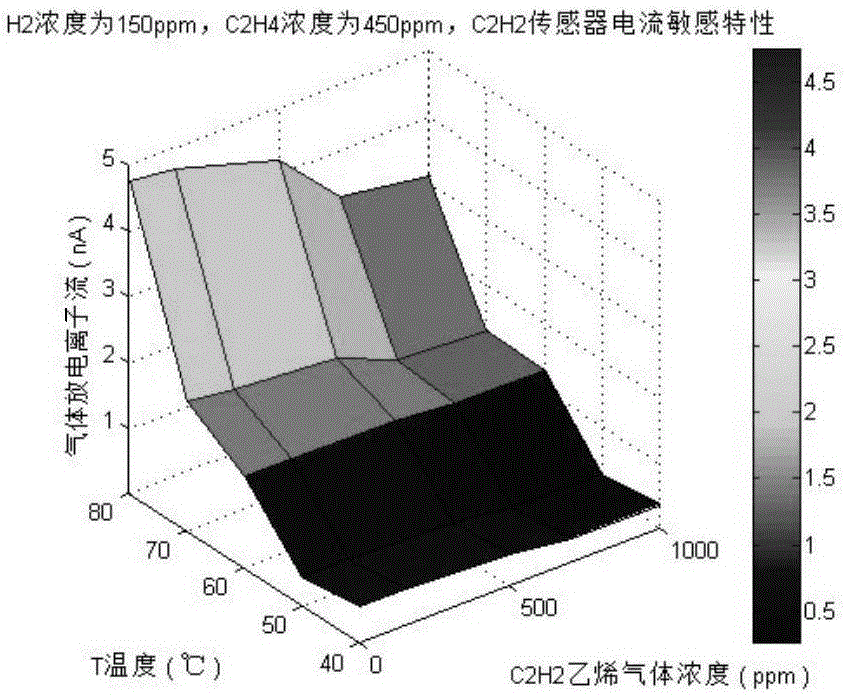

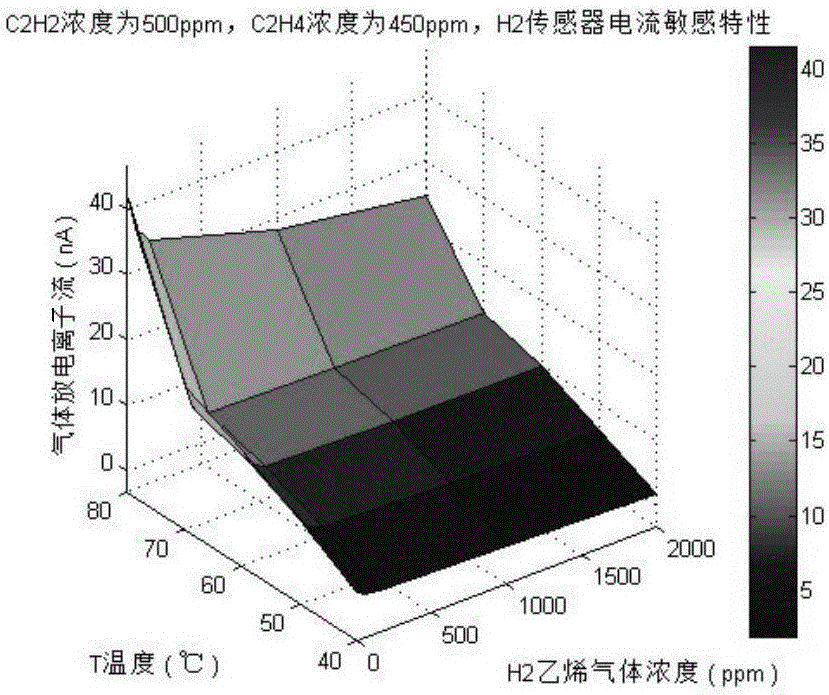

[0084] The basic structure of this embodiment is the same as that of Embodiment 1, according to image 3 , Figure 4 The gold nanoporous film three-electrode ionization sensor array with temperature compensation function is shown, one sensor in the array is used to detect the temperature, and the other two sensors are used to detect the mixed gas concentration. The cathodes of the three sensors are made on the same pole plate, the three extraction poles and the collector poles have the same structure, and the three sensors have different pole spacings. The pole spacing of the sensors in the array is set according to the diameter of the vent hole, the lead-out hole, the side length and the hole depth of the deep groove. One of the sensors is used to detect C 2 h 2 Gas concentration, the electrode surface of the first electrode has 6 circular air holes of Φ3mm, the ratio of the electrode spacing between the first electrode and the second electrode to the aperture of the small...

Embodiment 3

[0095] The basic structure of this embodiment is the same as that of Embodiment 1, according to image 3 , Figure 4 The gold nanoporous film three-electrode ionization sensor array with temperature compensation function is shown, one sensor in the array is used to detect the temperature, and the other three sensors are used to detect the concentration of the mixed gas. The cathodes of the four sensors are made on the same plate, the four extraction poles and the collector poles have the same structure, and the four sensors have different pole spacings. The pole spacing of the sensors in the array is set according to the diameter of the vent hole, the lead-out hole, the side length and the hole depth of the deep groove. One of the sensors is used to detect C 2 h 2 For gas concentration, the electrode surface of the first electrode has 8 small air holes with a diameter of 3mm, and the ratio of the distance between the first electrode and the second electrode to the diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com