Liquid nitrogen filling machine

A filling machine, liquid nitrogen technology, applied in mechanical equipment, gas/liquid distribution and storage, ship construction details, etc., can solve the problem that the floating ball cannot guarantee strict blocking of the column spacer, the pressure sensor cannot accurately transmit, and cannot be eliminated. temperature error and other problems, to achieve the effect of eliminating the influence of temperature, eliminating errors and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is described further as follows:

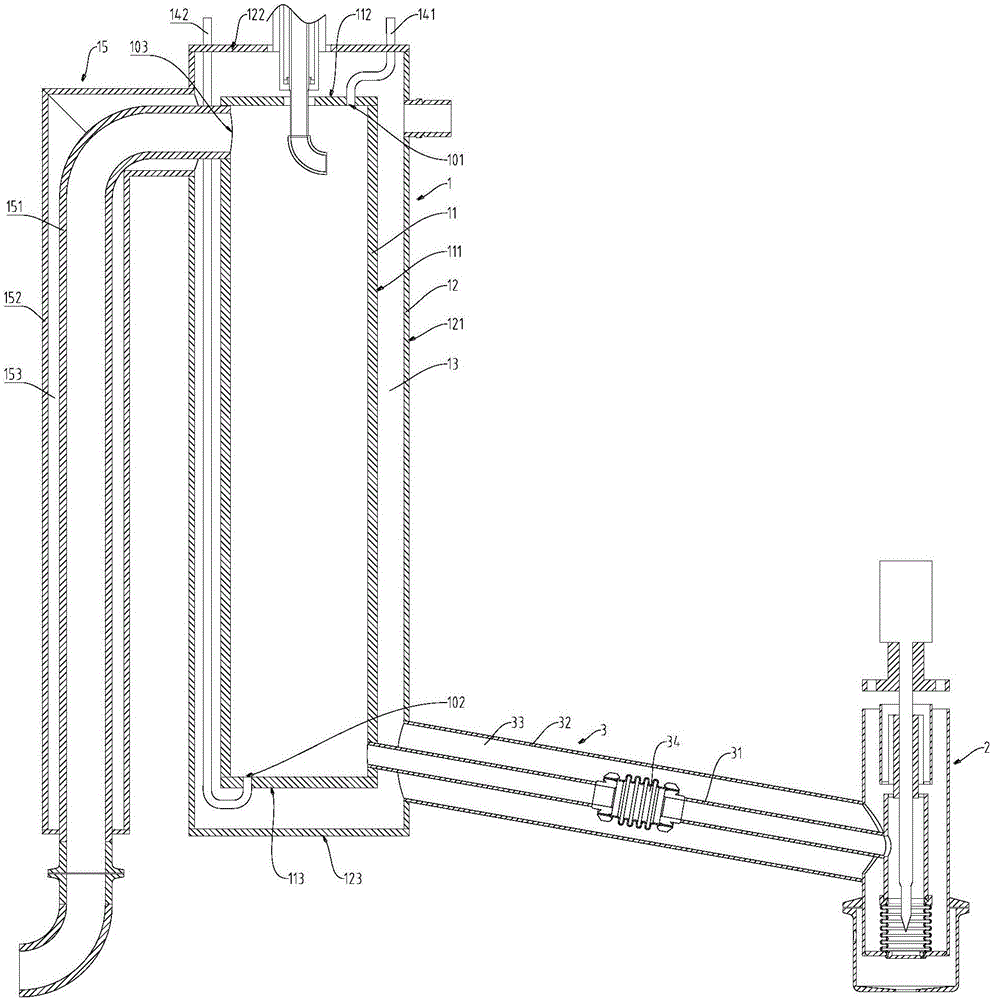

[0018] liquid nitrogen filling machine, such as figure 1 As shown, it includes heat preservation storage cylinder 1, heat preservation filling head 2 and heat preservation infusion tube 3; The end is provided with the bottom installation hole 102 extending to the inner cavity of the heat preservation storage cylinder 1; it includes a first pressure introduction pipe 141 and a second pressure introduction pipe 142; one end of the first pressure introduction pipe 141 is installed in the top installation hole 101, and the other One end extends above the thermal insulation storage cylinder 1 ; one end of the second pressure introduction pipe 142 is installed in the bottom mounting hole 102 , and the other end extends above the thermal insulation storage cylinder 1 .

[0019] In this liquid nitrogen filling machine, the thermal insulation storage cylinder 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com