Universal-precaution bullet-proofing structure and cab and bullet-proofing car

A cab, a comprehensive technology, applied in the direction of protective clothing, protective equipment, protective equipment, etc., can solve the problems of poor strength, low density, and limited application range of composite materials, and achieve improved ballistic performance, light weight, and strong safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

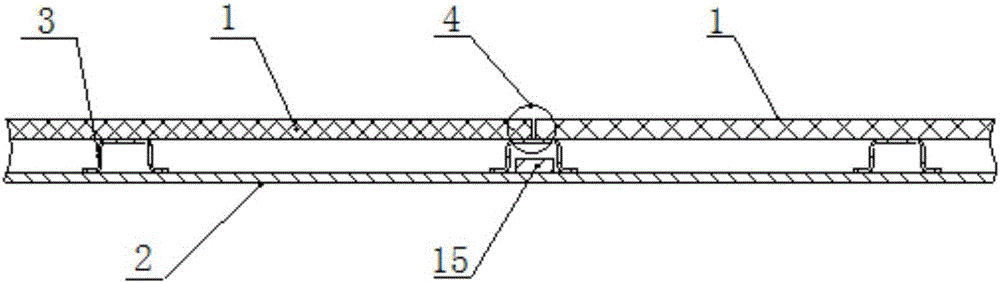

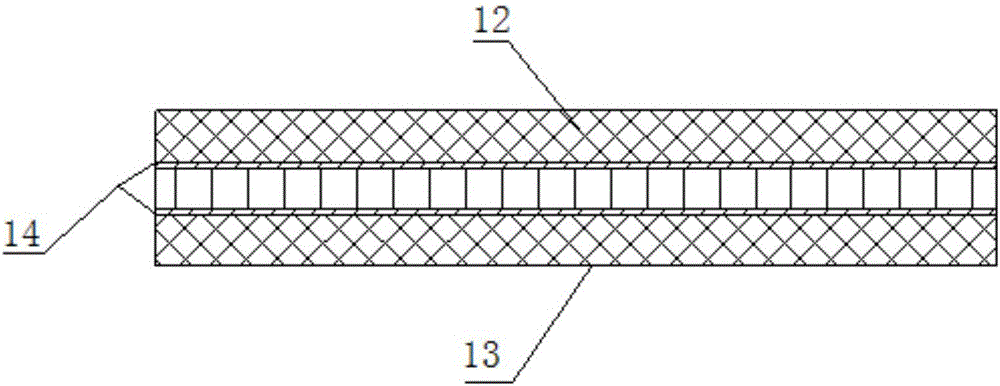

[0034] Such as Figure 1-Figure 2 As shown, a comprehensive protection bulletproof structure includes a first layer body structure and a second layer body structure 2, the first layer body structure includes a plurality of bulletproof panels 1 connected to the second layer body structure 2, and the bulletproof panels 1 There is a set gap 4, and the bulletproof structure is provided with a bulletproof block 15 corresponding to the gap 4. The bulletproof blocks 15 are arranged in the gaps between the bulletproof plates 1, so that the entire structure can be bulletproof, forming comprehensive protection, and having higher safety.

[0035] The bulletproof block 15 can be arranged between the first layer structure and the second layer structure, and be connected to the second layer structure 2, or the bulletproof block 15 can be arranged outside the first layer structure, and be connected A bulletproof block is arranged on the bulletproof board 1 , that is, outside the gap between...

Embodiment 2

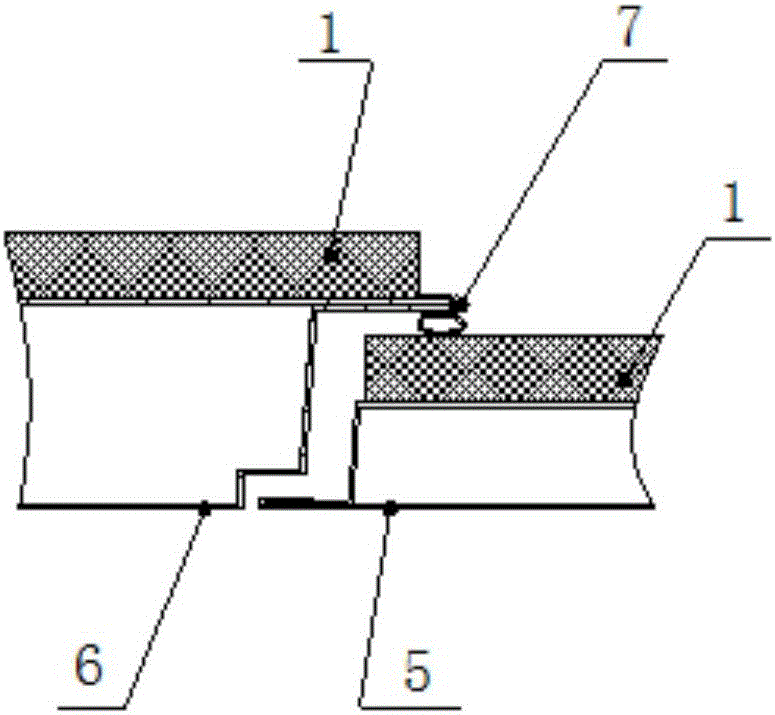

[0042] A comprehensive protection bulletproof cab comprises a cab body made of the comprehensive protection bulletproof structure of embodiment 1. The bulletproof structure is applied to the cab, the second layer structure 2 corresponds to the cab skin, and the connector 3 corresponds to the cab structural beam. The cab is lightweight and modular, and the cab has all-round protection capabilities.

[0043] The driver's cab body includes a front wall, a side wall, a rear wall and a top cover connected together, the side wall is provided with a door body, and the front wall and the side wall are detachably provided with bulletproof glass 11 . The various parts of the cab are modularized, and bulletproof components of different thicknesses can be installed according to different protection level requirements. Lightning protection equipment is arranged on the bottom floor of the cab body. The cab protection components are modularly grouped, and different protection components ca...

Embodiment 3

[0050] A bulletproof vehicle comprises the bulletproof cab of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com