Biomass particle air heating furnace

A biomass pellet and hot blast stove technology, applied in lighting and heating equipment, combustion method, combustion air/fuel supply, etc., can solve the problem of high furnace temperature, tempering, and insufficient combustion of biomass pellets to discharge black smoke pollution environmental issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following descriptions are only preferred embodiments of the present invention, and do not limit the protection scope of the present invention. The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

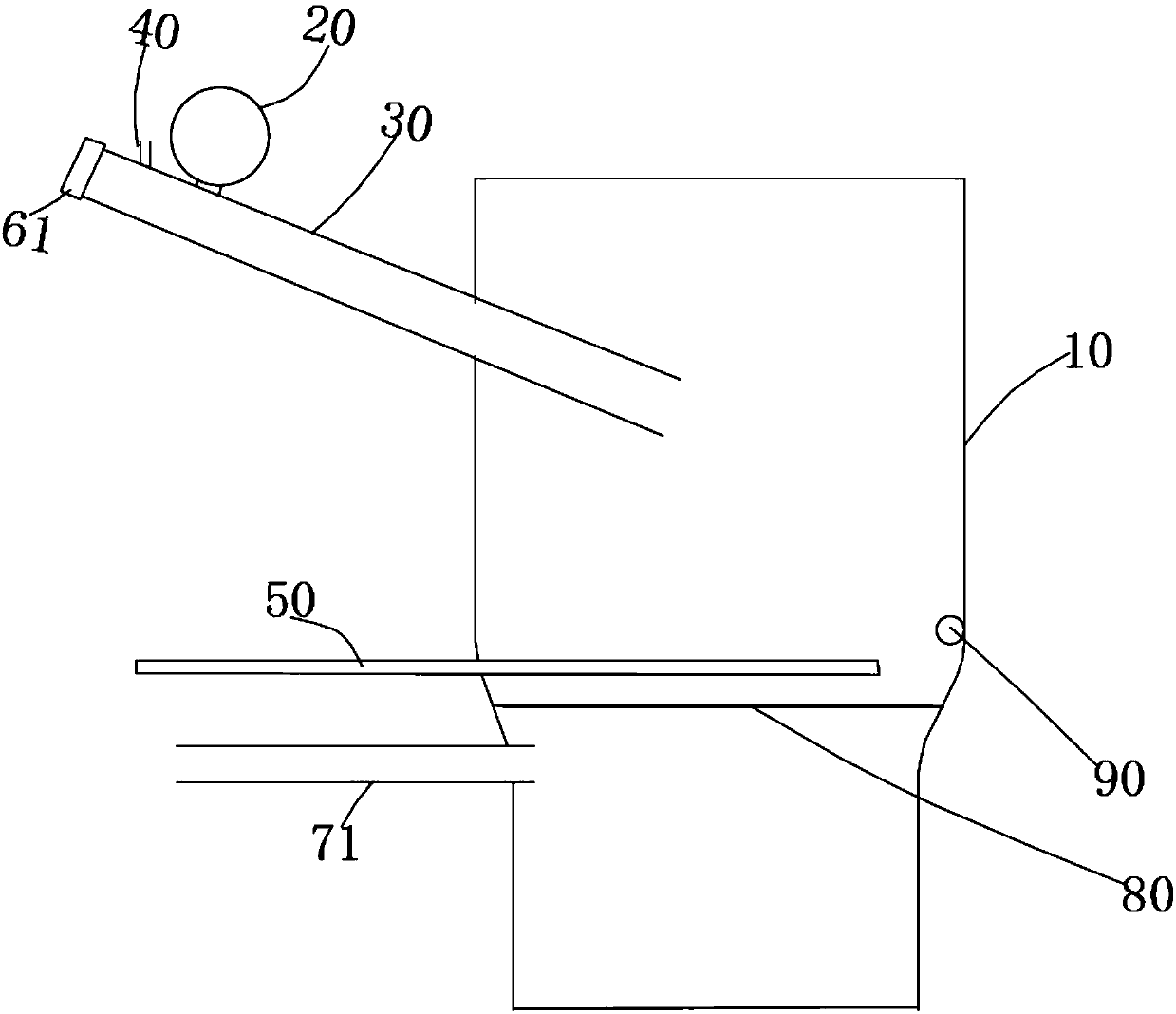

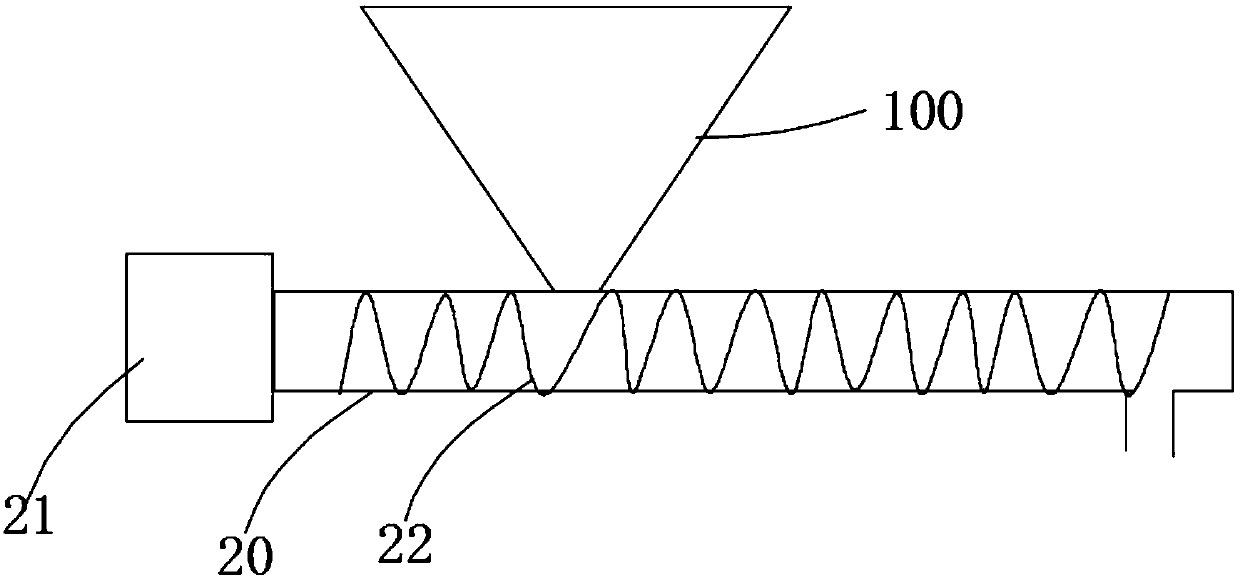

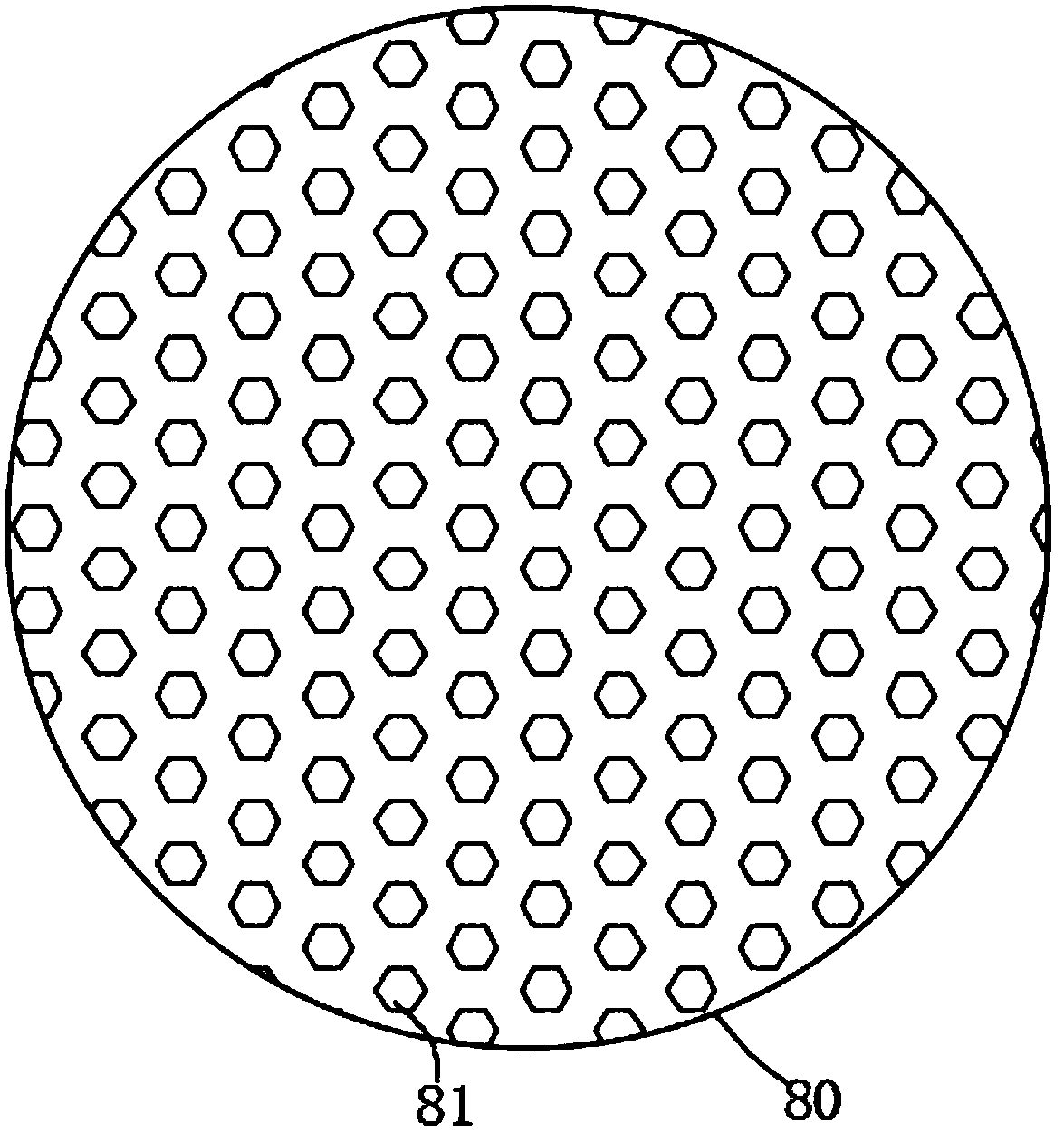

[0022] Examples, see Figure 1 to Figure 3 Shown: a biomass particle hot air stove, including a furnace body 10, a heating device and a silo 100, characterized in that it also includes a conveying pipe 30 and a screw conveyor 20, and the inlet of the screw conveyor 20 is connected to the silo 100 , wherein one end of the conveying pipe 30 is connected to the outlet of the screw conveyor 20, and the other end extends into the furnace body 10, wherein the inner wall of the conveying pipe 30 is smooth and the inclination angle with the horizontal direction is less than 90 degrees. The silo 100 enters the screw conveyor 20, and the motor 21 connected to the screw conveyor 20 controls the rotation of the screw ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com