Boiler slagging condition monitoring and controlling methods based on outlet temperature of combustion chamber

A furnace outlet and control method technology, applied in the direction of boiler working status indication, control system, lighting and heating equipment, etc., can solve the problems of shutdown installation, difficulty in power station boilers, and troublesome heat flow meter layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the technical means, creative features, workflow, and usage methods of the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

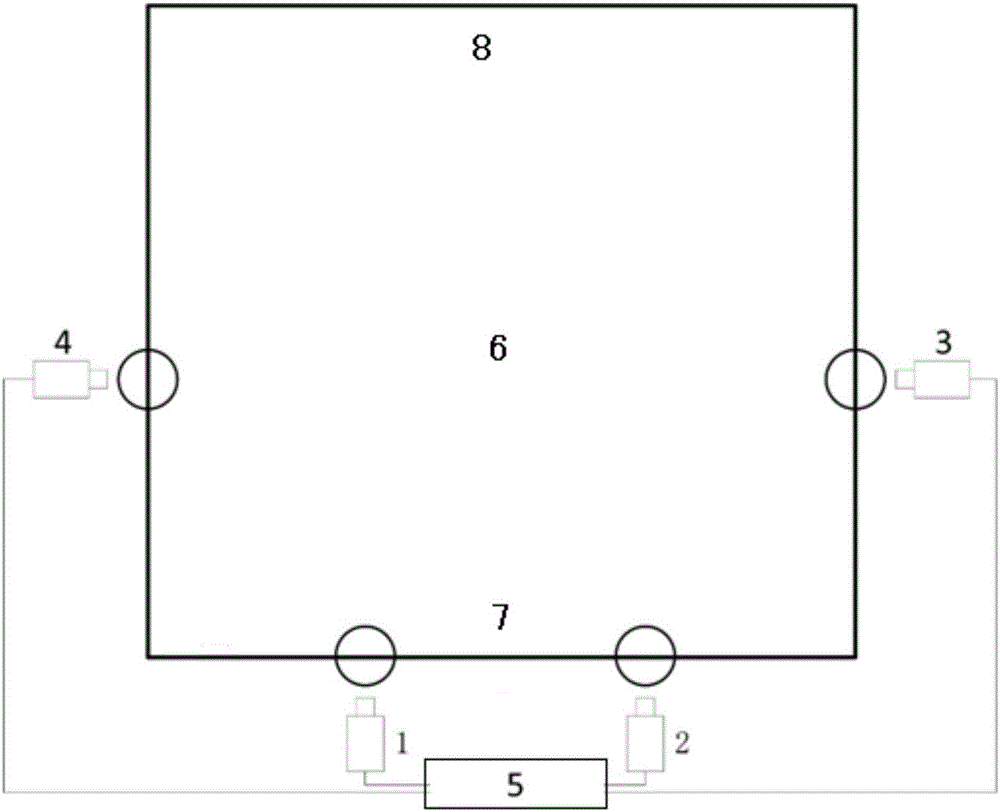

[0055] figure 1 It is a schematic diagram of the installation of the furnace outlet temperature matrix measurement method in this embodiment, including CCD1, CCD2, CCD3, CCD4 and a portable computer 5. The upper part of the furnace 6 is the rear wall 8, and the lower part is the front wall 7. Each CCD is installed on the furnace 6 to record the flame radiation image at each fire viewing hole. The image is segmented and extracted by computer, and the temperature is calculated to obtain the furnace outlet temperature. Matrix and the temperature change rate of the corresponding measuring points of each CCD, and then predict the commissioning time of the soot blower, reflecting the cleanliness of the water wall and the slagging characteristics of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com