High-speed axle steel material and heat treatment method thereof

A heat treatment method and axle steel technology are applied in the field of high-speed axle steel materials and their heat treatment, which can solve the problems of large component segregation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

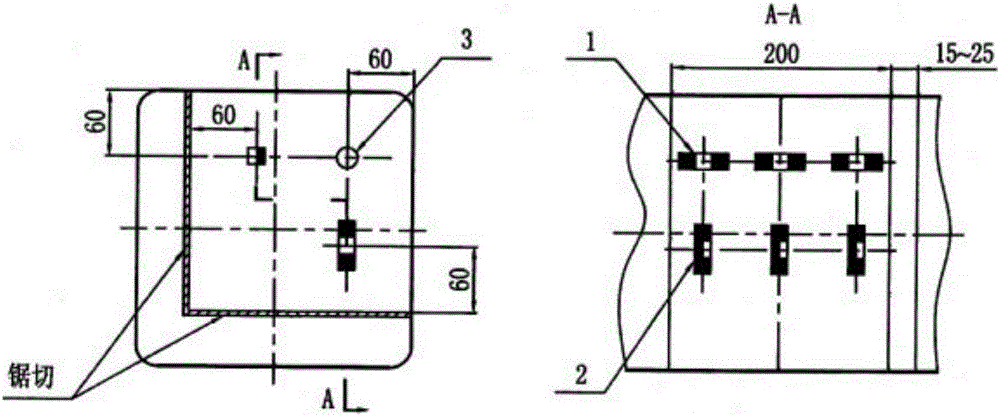

[0028] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

[0029] The invention provides a high-speed axle steel material, and the technical problems to be solved are as follows:

[0030] 1) Design the chemical composition to meet the performance of the axle;

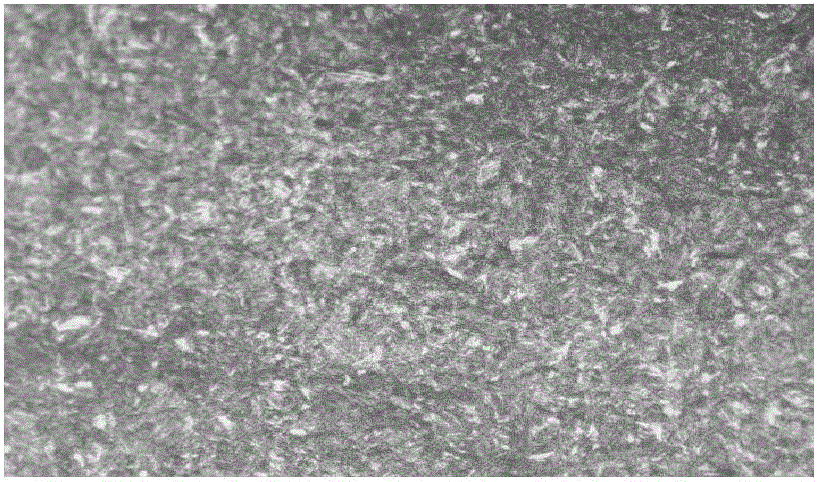

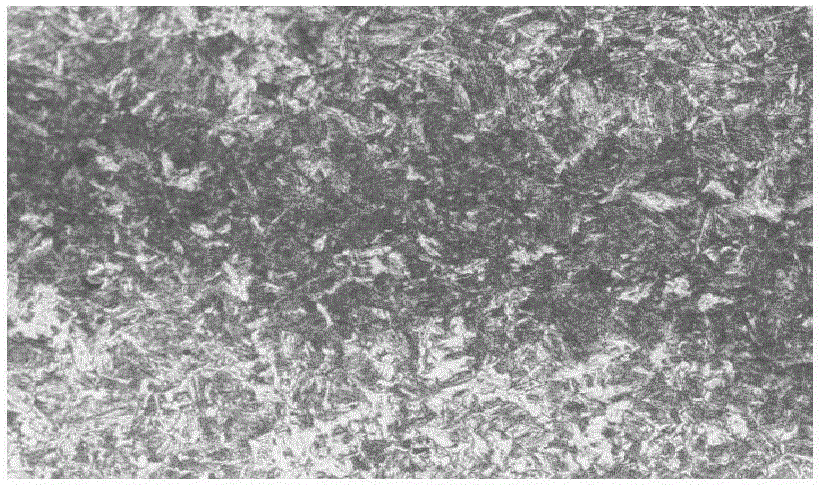

[0031] 2) Explore the heat treatment system for refining the grain of the shaft blank;

[0032] 3) Develop a smelting process to reduce the size of inclusions;

[0033] 4) Find a production method to reduce component segregation;

[0034] 5) Improve the fatigue limit of high-speed axle steel.

[0035] In order to solve the above technical problems, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fatigue limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com