Quenching apparatus used for excavator supporting wheel shaft head and shaft neck portion

A technology of supporting roller shafts and quenching equipment, which is applied in the field of metal quenching, can solve problems such as non-environmental protection, peeling off blocks, and steep hardness gradients in the transition zone, and achieve the effects of improving work efficiency, reducing heating times, and saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

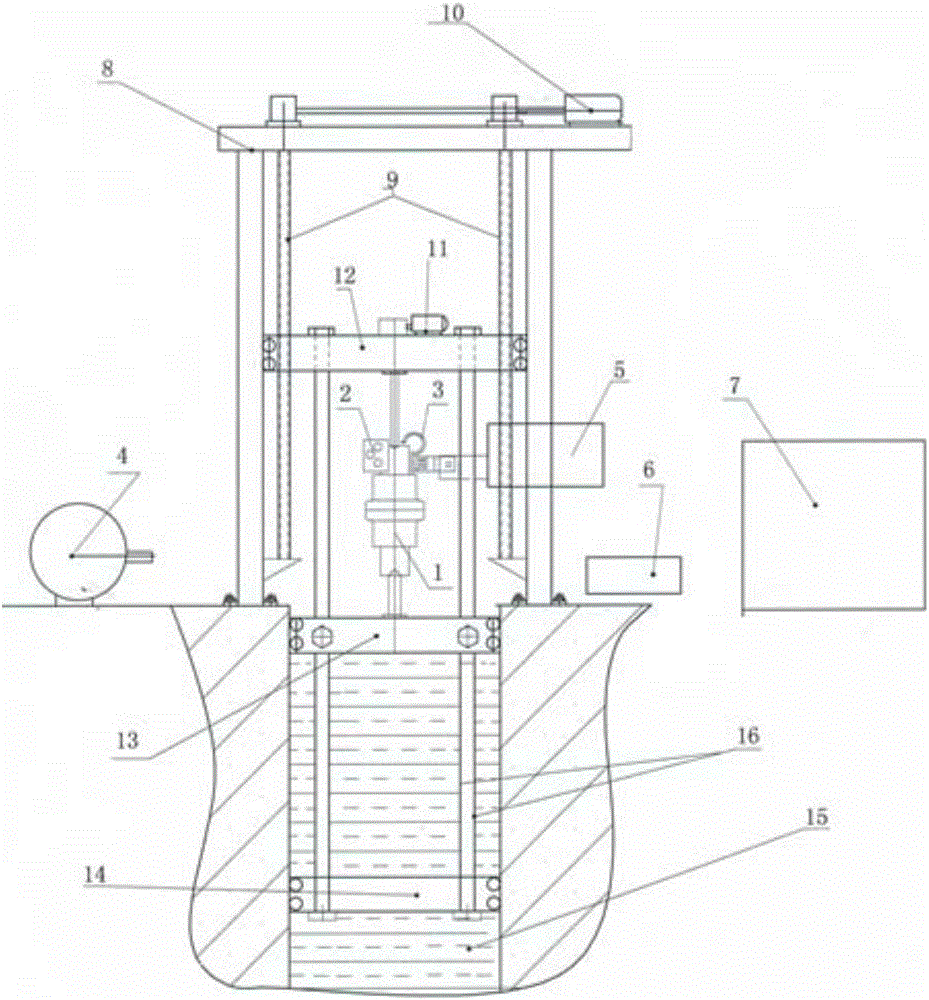

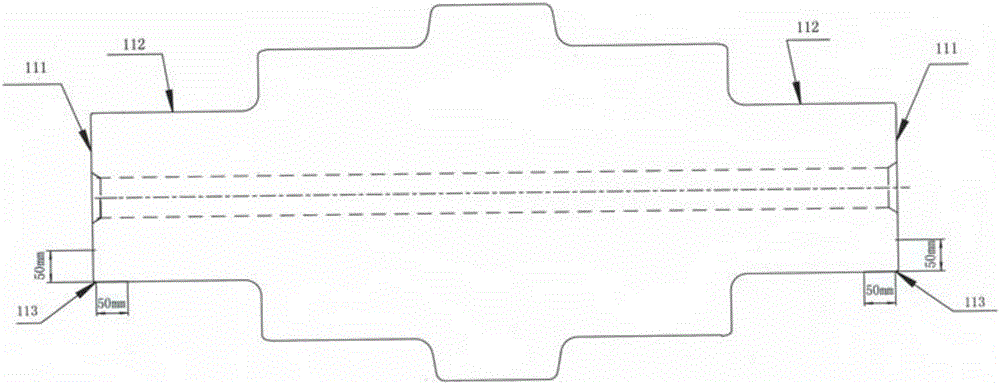

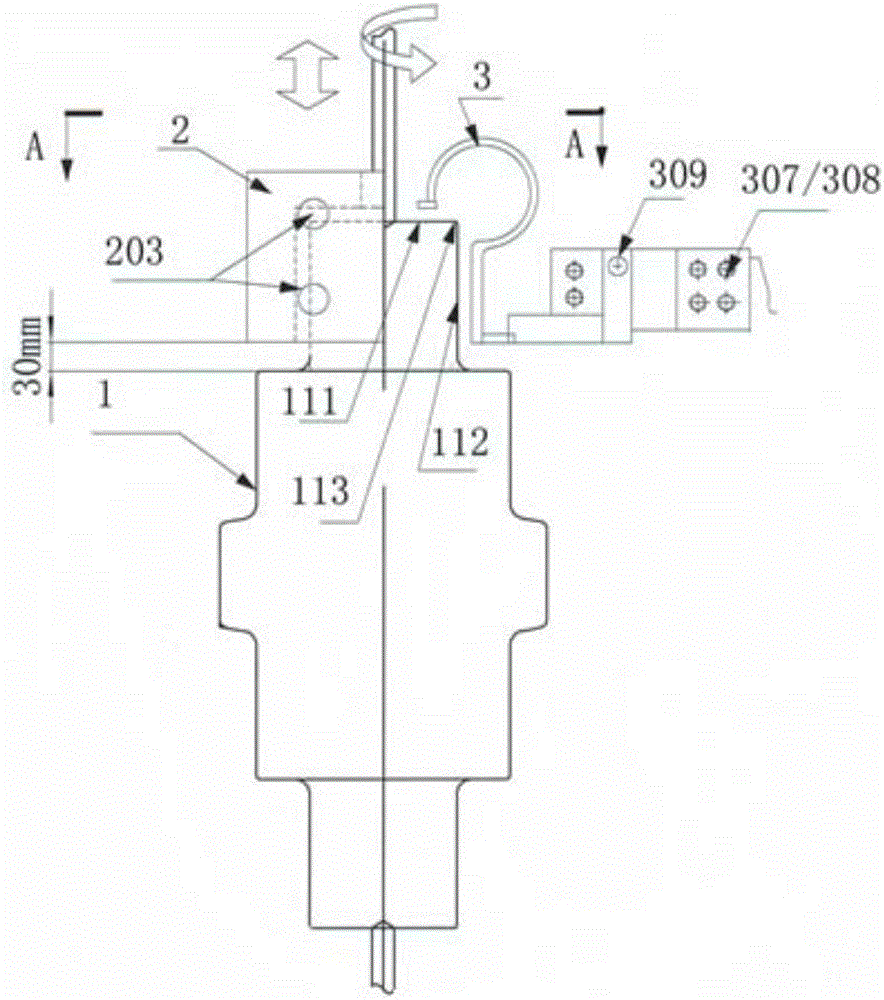

[0048] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0049] see Figure 1-8 .

[0050] The quenching device of the present invention and its embodiments are aimed at supporting wheels of large excavators, and are also suitable for supporting wheels of other large crawler excavators.

[0051] The present invention is a quenching device for the shaft head and neck of the supporting wheel of an excavator, comprising a medium frequency induction hardening machine tool, a quenching water spraying quenching mechanism (2) for the shaft part and the end of the supporting wheel, the shaft part and the end of the supporting wheel Induction hardening heater (3), cooling water bag (4), reservoir (15), console;

[0052] The medium-frequency induction hardening machine tool includes three parts: a mechanical transmission part, a power supply part, and a cooling part. The mechanical transmission part includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com