Device and method for regulating warping of glass plate

A glass plate and warping technology, which is applied in the field of devices for adjusting glass plate warping, can solve problems such as glass plate cracks, broken plates, and affecting production, and achieve the effects of improving the holding force, increasing friction, and eliminating bad warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

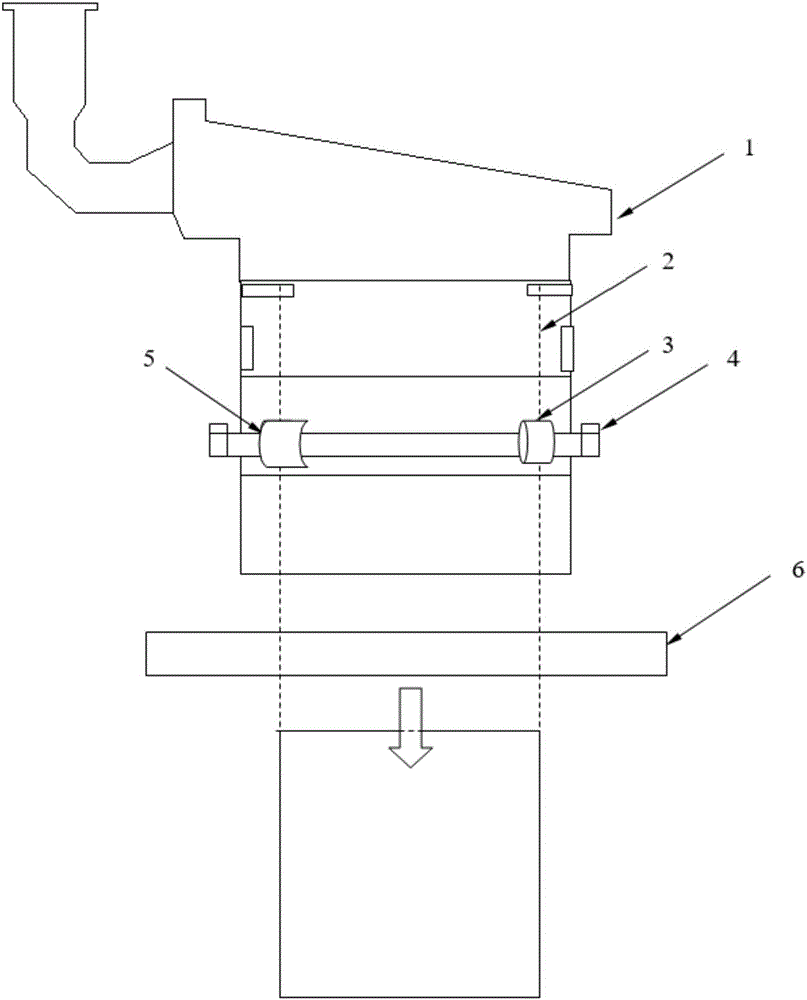

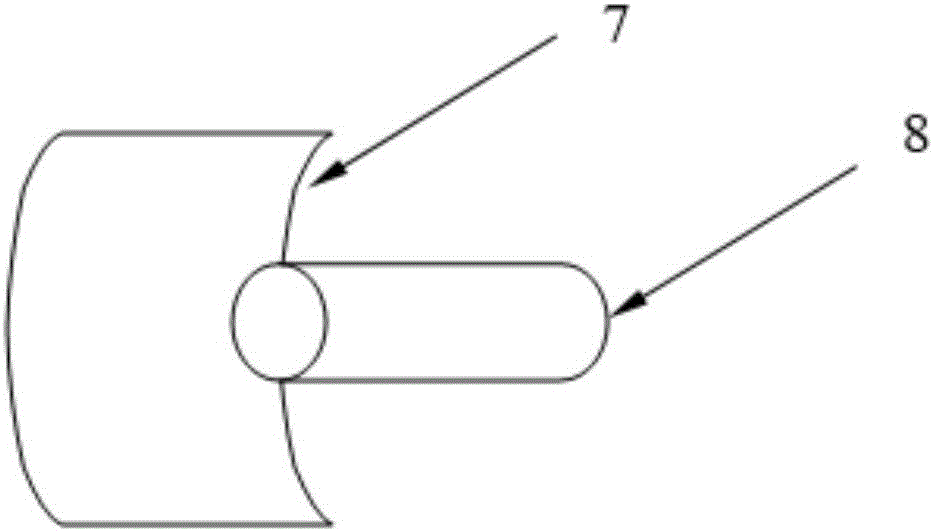

[0027] see figure 1 and figure 2 , the present invention comprises overflow down-draw forming equipment 1, overflow down-draw forming equipment 1 rear end is provided with cutting glass plate equipment 6, is provided with traction roller 4 between overflow down-draw forming equipment 1 and cutting glass plate equipment 6, overflow down-draw forming The equipment 1, the traction roller 4 and the cutting glass plate equipment 6 are on the same plane, and the traction roller 4 is provided with an arc-shaped friction device 5 for increasing friction. The device 7 is a rear-end lead screw propulsion device 8 that moves on the traction roller 4. The traction roller 4 is provided with a traction roller boss 3, the contact surface of the traction roller boss 3 is a rough surface, and the width of the traction roller boss 3 is smaller than that of the traction roller 4. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com