Multi-linked type softened water control valve system and working method thereof

A working method and technology of control system, applied in control/manipulation system, water treatment parameter control, chemical instrument and method, etc., can solve the problems of difficult interval control, inconvenience, and difficulty in ensuring the continuity and effectiveness of soft water supply. , to achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further explained below in conjunction with the accompanying drawings.

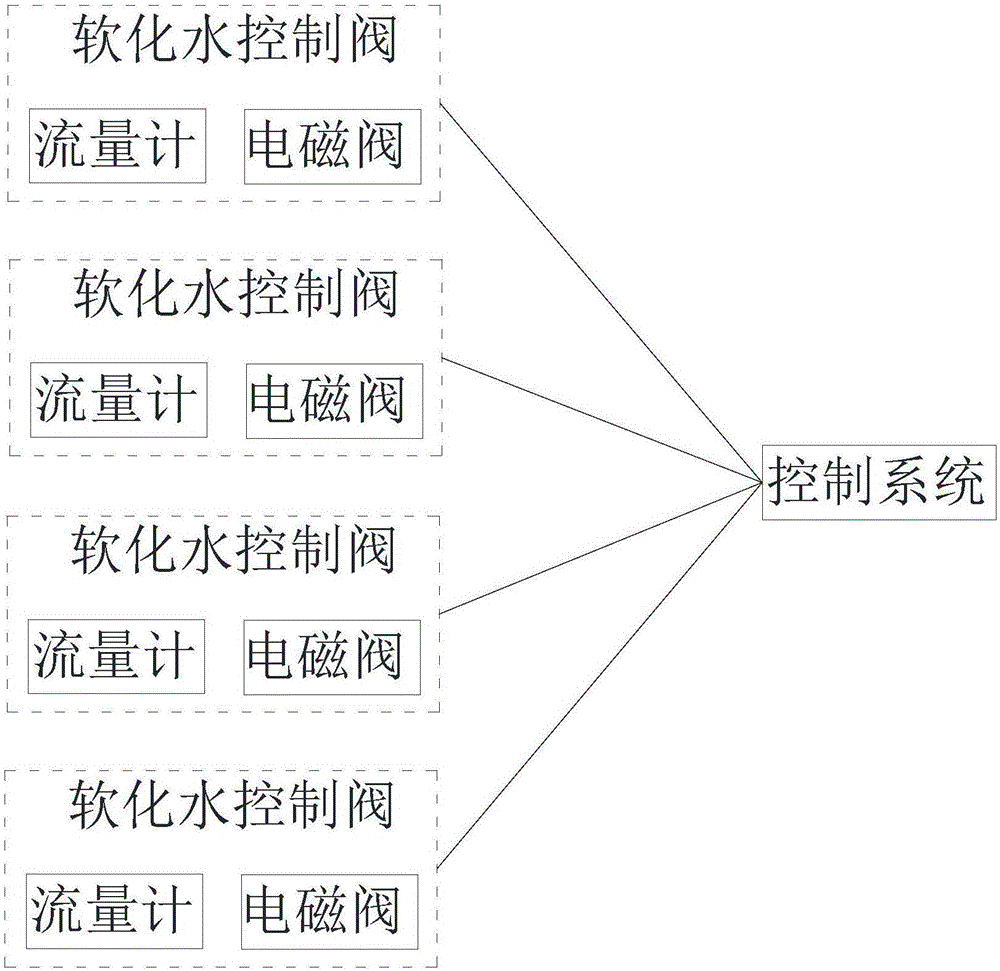

[0012] Such as figure 1 As shown, a multi-unit linkage softened water control valve system of the present invention includes at least two softened water control valves arranged in parallel. The water outlet of the softened water control valve is equipped with a flow meter and a solenoid valve. The flow meter is used to measure The water production of the softened water control valve, the solenoid valve is used to close the water outlet of the softened water control valve, the softened water control valve, the flow meter and the solenoid valve are all connected to the control system through the data line, and the control system is used to count the water production data of the softened water control valve , and send control signals to the softened water control valve and solenoid valve.

[0013] According to the working method of the above-mentioned softened water cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com