Novel double-drum balanced driving device and using method

A balanced drive, double drum technology, applied in the field of mining machinery, can solve the problems of uneven drum wear and unbalanced power loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

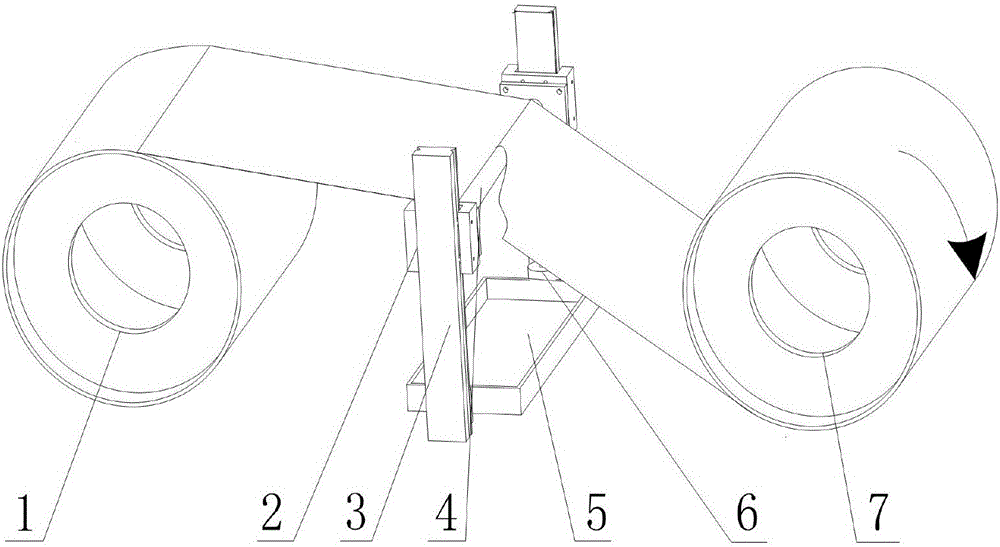

[0016] The present invention proposes a novel dual-drum balance driving device and its use method;

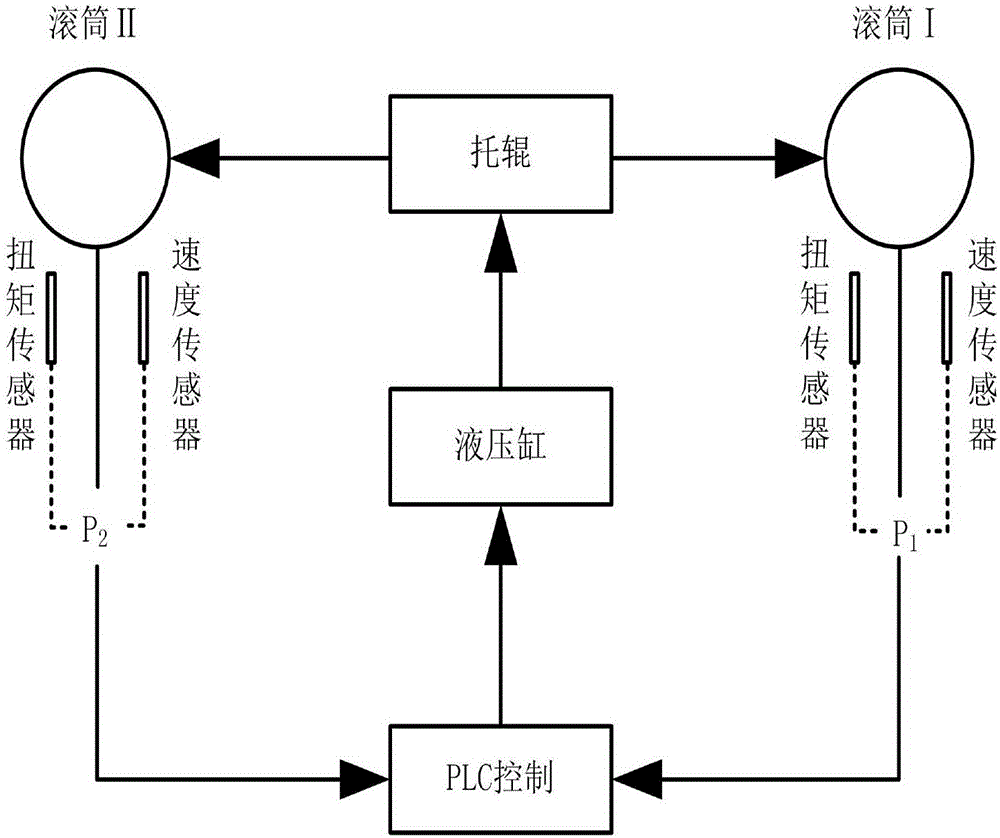

[0017] The PLC control system includes a torque sensor, a speed sensor, a motor, a hydraulic pump and a hydraulic cylinder; the torque sensor and the speed sensor are connected to the drum shaft; the motor is connected to the hydraulic pump, and the hydraulic pump is connected to the hydraulic cylinder;

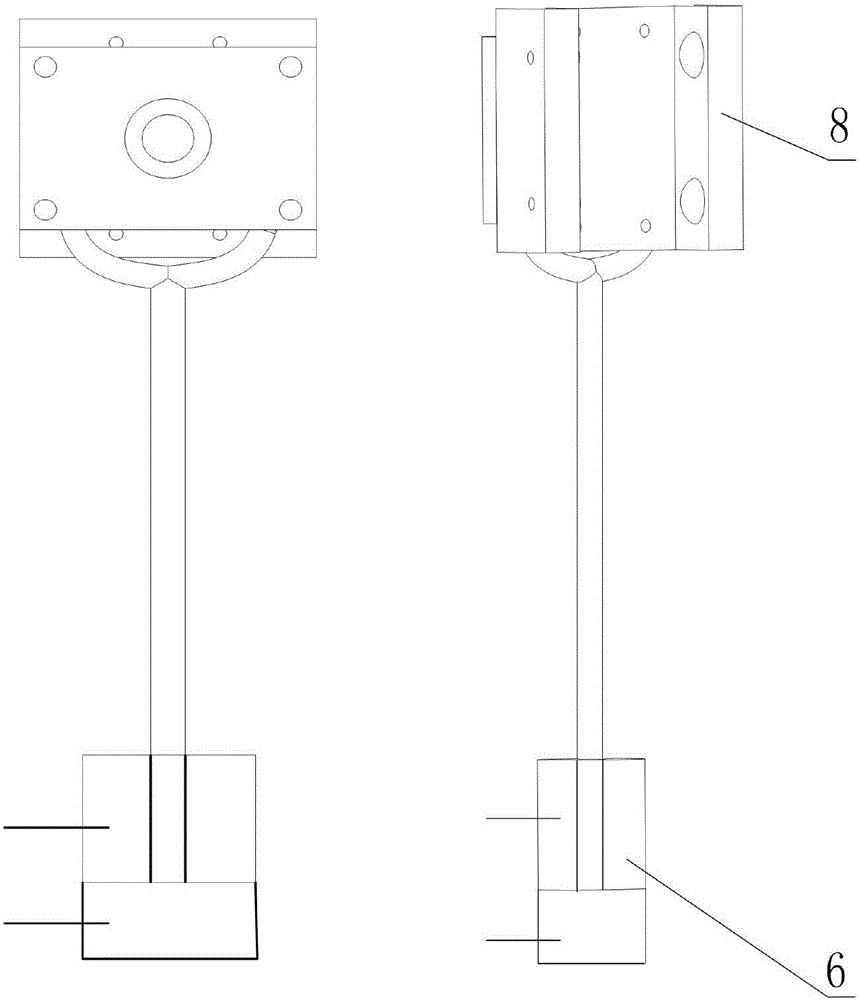

[0018] The slider mechanism is fixed on the fixed frame 3 between the two rollers and driven by the hydraulic cylinder to move up and down;

[0019] The idler roller is installed on the idler groove on the slider mechanism;

[0020] The material holding box is arranged directly under the idler roller between the two rollers, and is used to load the sundries left by the idler roller to clean the conveyor belt.

[0021] The use process is:

[0022] In the first step, when the drum I7 and the drum II1 are working, the torque sensor and the speed sensor are input into the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com