Battery management system and method

A battery management system and battery pack technology, applied in battery circuit devices, terminal battery switching devices, electrical components, etc., can solve the problems of high cost, low reliability, and aggravate the charging and discharging characteristics of battery cells, so as to achieve low cost and high performance. The effect of power balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

[0031] Moreover, in different implementations, the same reference numerals or signs may be used, but this does not represent a structural or functional connection, but is only for convenience of description.

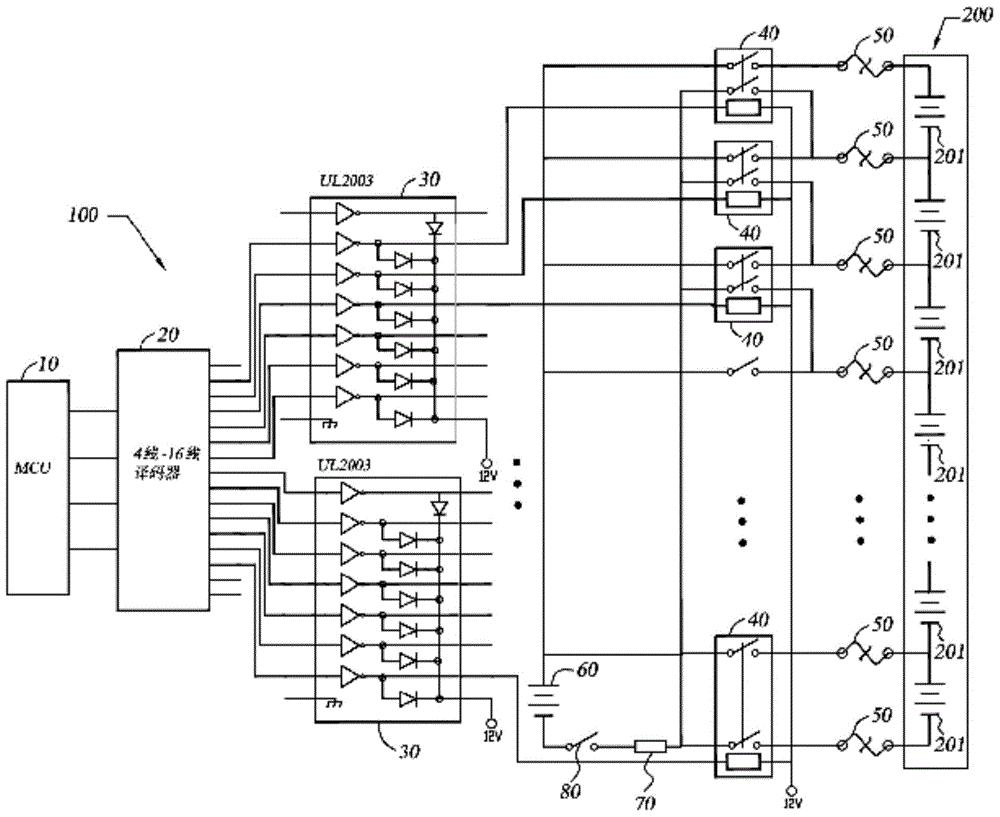

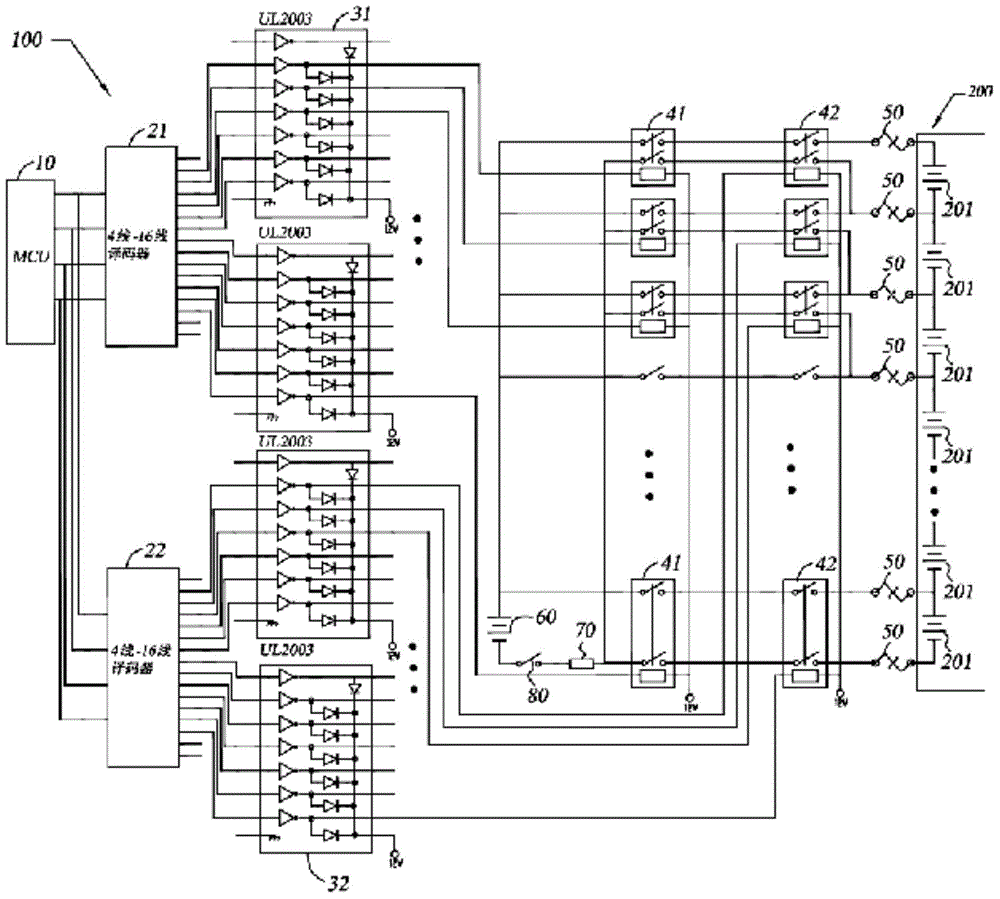

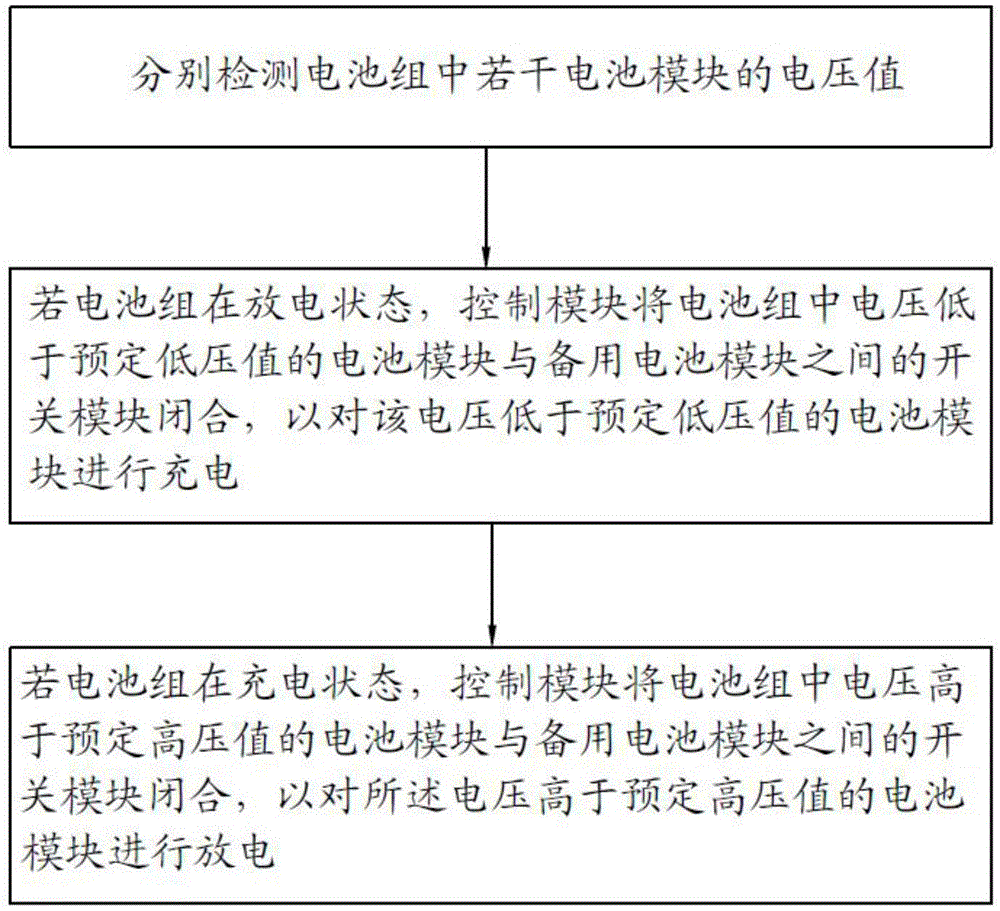

[0032] ginseng figure 1 , to introduce a specific implementation manner of the battery management system 100 of the present invention. In this embodiment, the battery management system 100 includes a backup battery module 60 , several switch modules 40 , and a controller 10 .

[0033] The number of switch modules 40 corresponds to the number of battery modules 201 in the battery pack 200 , and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com