Clean material processing device and its processing technology

A processing device and material technology, which is applied in the direction of conveying bulk materials, packaging, loading/unloading, etc., can solve the problems of low material processing efficiency, long manual operation process, pollution of the surrounding environment, etc., and achieve the effect of reducing manual labor and environmental protection Good, the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

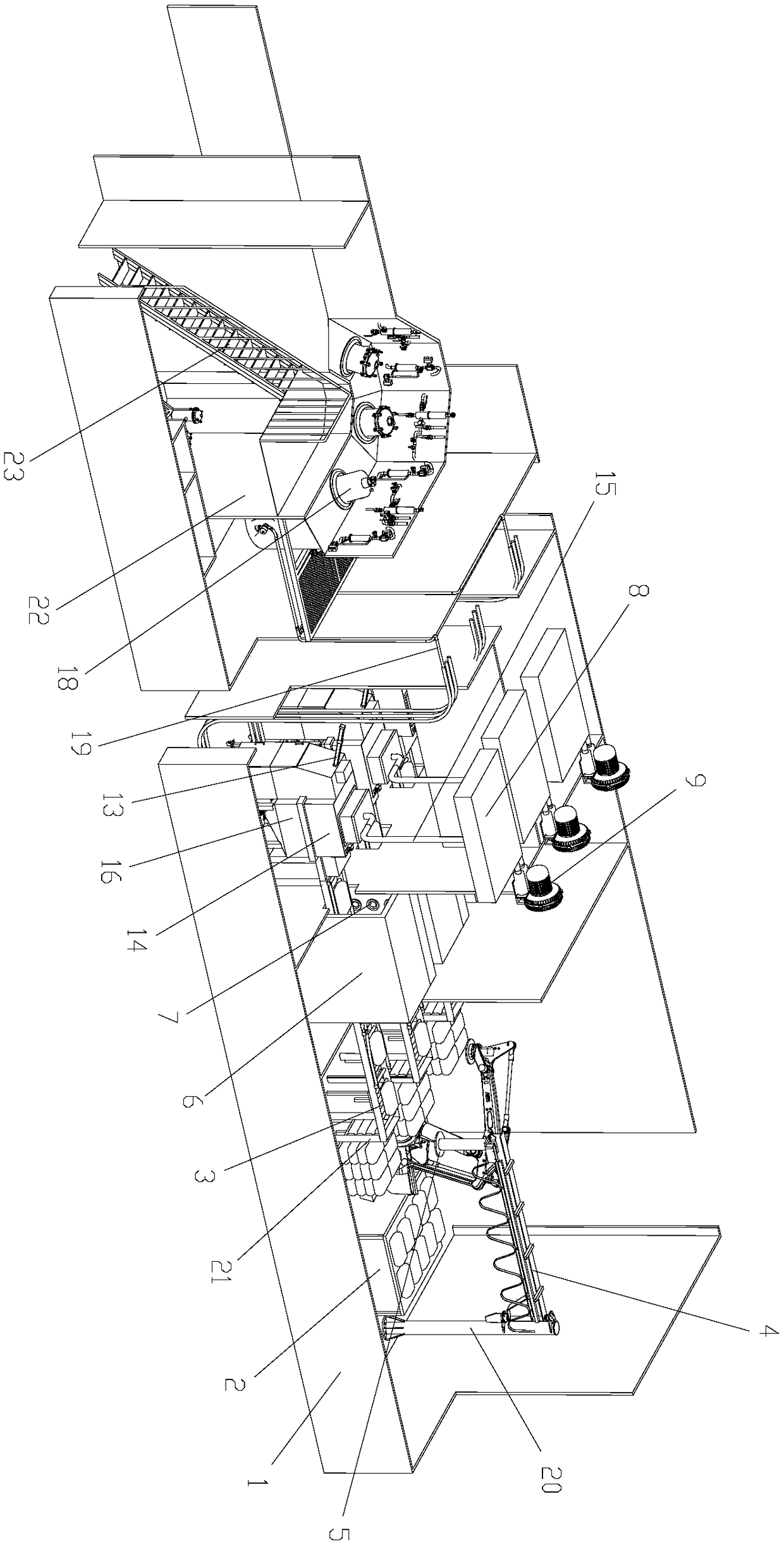

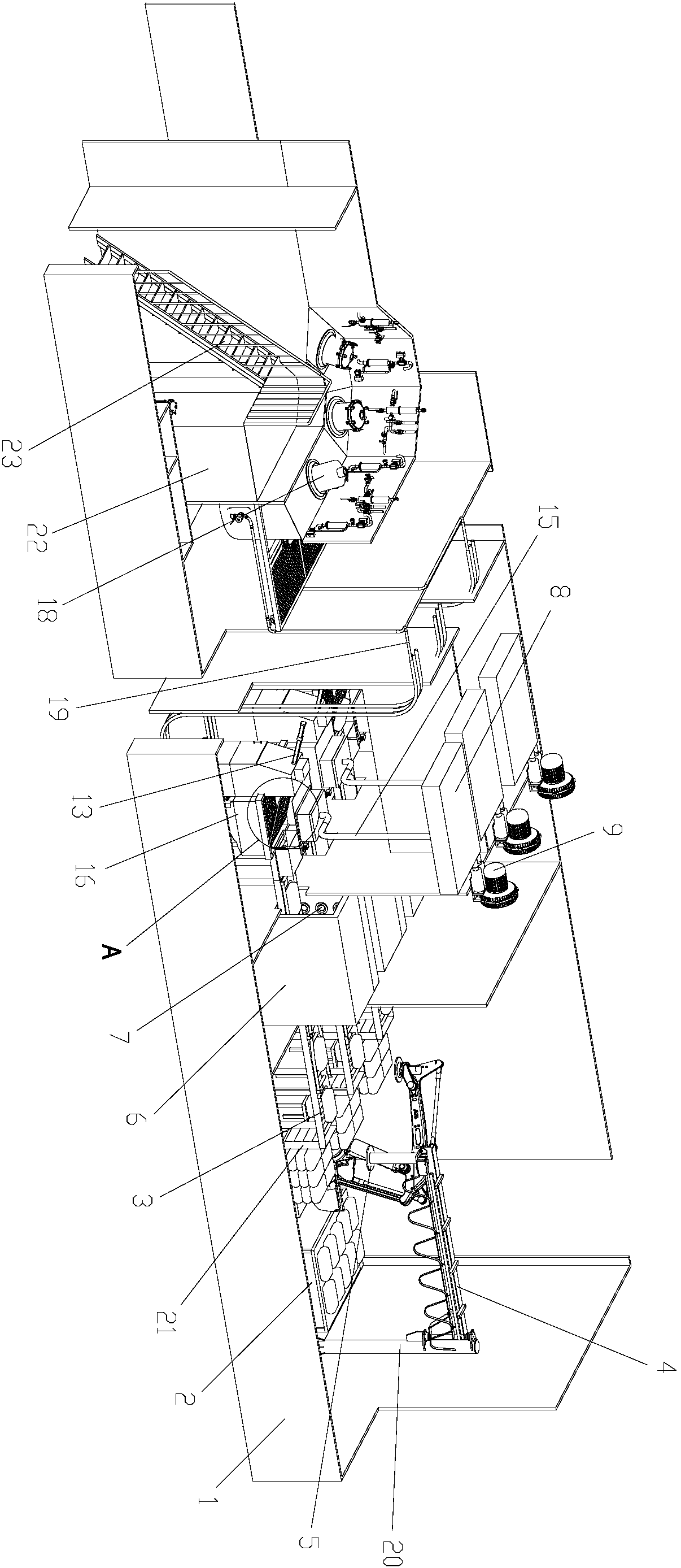

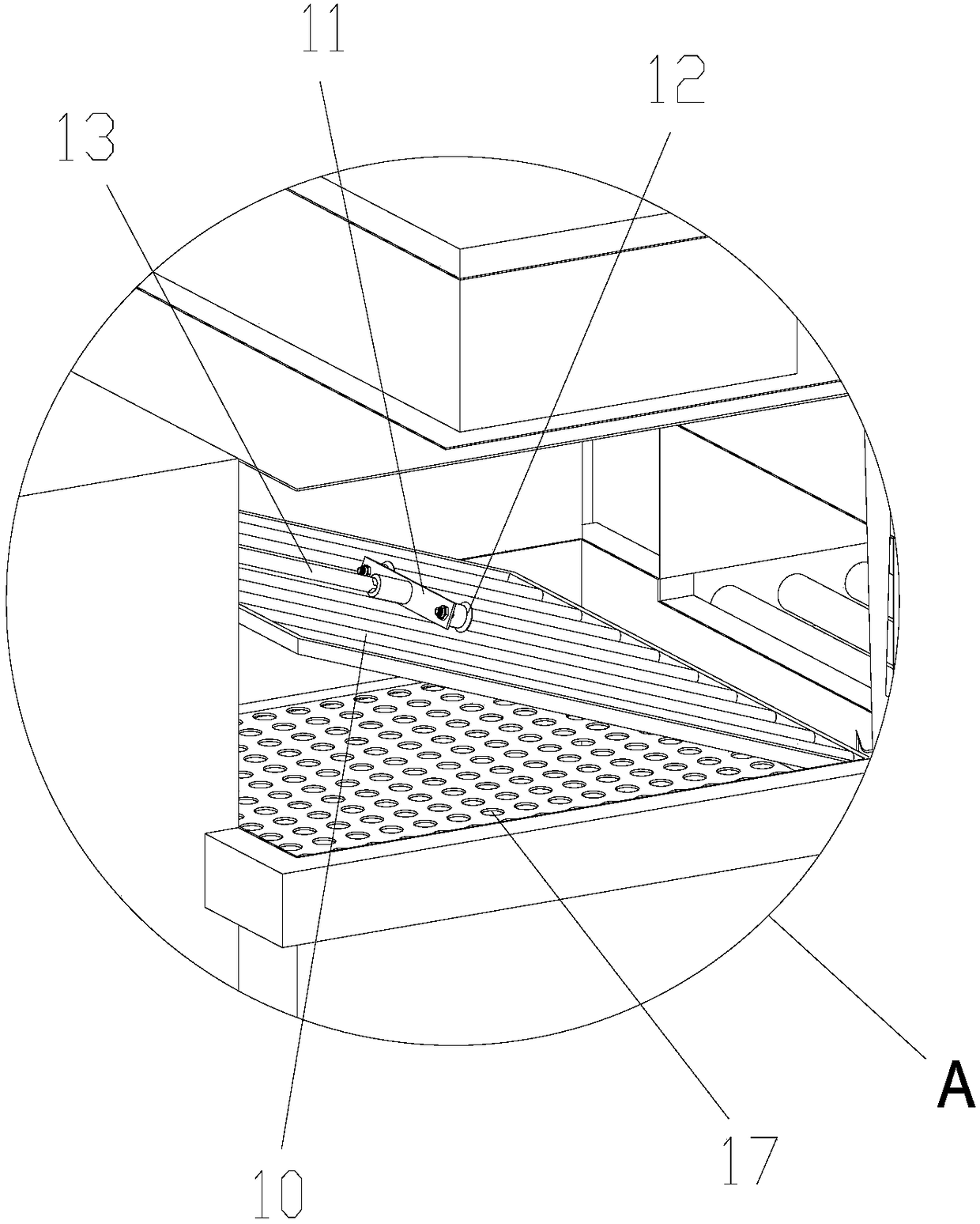

[0015] The present invention will be further described below in conjunction with accompanying drawing:

[0016] With reference to accompanying drawing: this clean material processing device among the present embodiment comprises frame 1, and one side of frame 1 is provided with feeding table 2, and one side of feeding table 2 is provided with a group of feeding belt 3, feeds The material belt 3 is set on the frame 1, the top of the feeding table 2 is provided with a grab arm 4, the outer end of the grab arm 4 is provided with a suction cup 5, the feed belt 3 is provided with an air shower room 6, and the air shower room 6 Set on the frame 1, a set of air outlets 7 is set in the air shower 6, a set of filters 8 are set on one side of the air shower 6, the filters 8 are set on the frame 1, and a fan is connected to the filter 8 9. The blower 9 is set on the frame 1, the outlet of the feed belt 3 is set with a grid plate 10, the grid plate 10 is set on the frame 1, and the scrape...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap