Method of manufacturing wooden-support miniature electric fan

A processing method and technology for electric fans, which are applied in wood processing utensils, manufacturing tools, wood stamping and other directions, can solve problems such as hidden dangers of environmental protection and the lack of beauty and interest in the appearance of miniature desktop fans.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

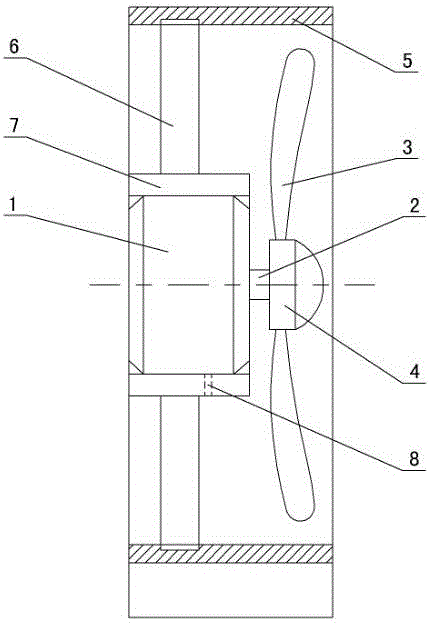

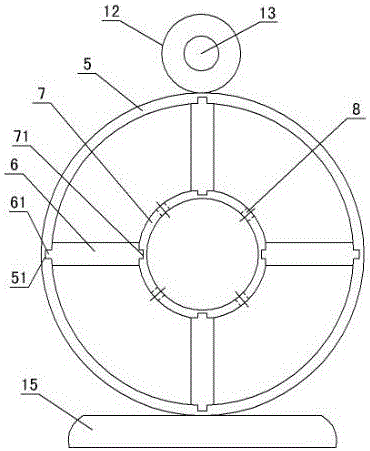

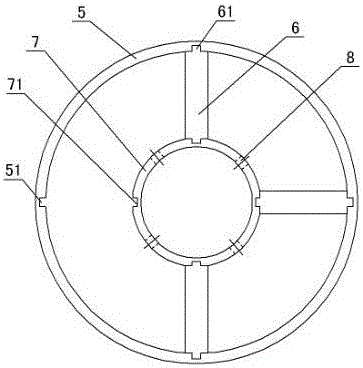

[0032] The present invention relates to a kind of processing method of wooden bracket miniature electric fan, such as figure 1 — Figure 7 As shown, including motor, blade and bracket, it is characterized in that the processing steps are as follows:

[0033] The first step is to process the outer fixed frame: take natural wood, and use woodworking machinery to make a circular or square outer fixed frame 5. During processing, the circular outer fixed frame is made of wood, and the wood is first cooked at high temperature treatment, high-temperature cooking temperature 100°C, cooking time of more than one hour, after cooking, the outer wall of the wood section is made into a cylindrical shape with woodworking machinery, and then the center is hollowed out to form a hollow cylinder. The square outer fixed frame is made of wooden boards Constitute a wooden square frame, and open the inner socket 51 in the inner wall of the outer fixed frame 5;

[0034]The second step is to proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com