Method for manually drilling hole in curved surface precisely in normal vector direction

A technology of normal vector direction and curved surface, which is applied in the field of curved surface machining, can solve the problems of large dependence on technical experience, increased equipment investment, and the risk of hole out-of-tolerance, etc., and achieve low operational difficulty, eliminate scrapped parts, and easy control of precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Below, a certain type of aircraft needs to make 16 holes of φ9.6mm on the curved surface of the wing root, and the verticality requirement is φ0.1mm as an example for further description. Among them, the root of the wing is a concave surface with a large curvature and an average radius of 450mm. Using the existing technology to carry out the operation experiment, the data are as follows:

[0031] Select a junior operator, an intermediate operator, a senior operator, an operating technician, and a senior operating technician who are equipped with aircraft riveting fitters, and respectively operate 16 holes on the above-mentioned wings. Through experimental measurements, the corresponding average The verticality is: φ2 mm, φ1.8 mm, φ1.2 mm, φ0.58 mm, φ0.36 mm, and the maximum verticality tolerance of a single hole is: φ2.8 mm, φ2.3 mm, φ1 .7 mm, φ0.69 mm, and φ0.48 mm. From this, it can be concluded that relying on personal experience and visually aligning the normal dir...

Embodiment 2

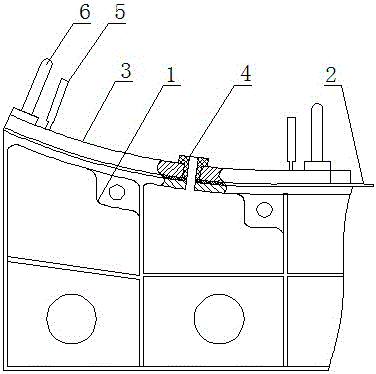

[0043] combined with Figure 1-3 As shown, a method for manually making holes on a surface accurately according to the direction of the normal vector includes the following steps:

[0044] 1.1 Install the skin 2 on the skeleton 1 and fix it in position;

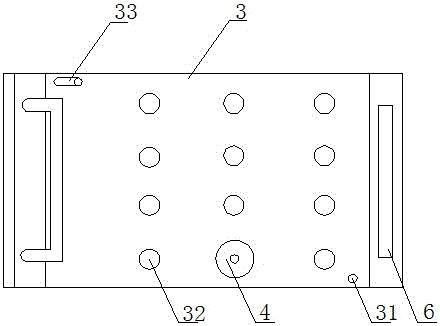

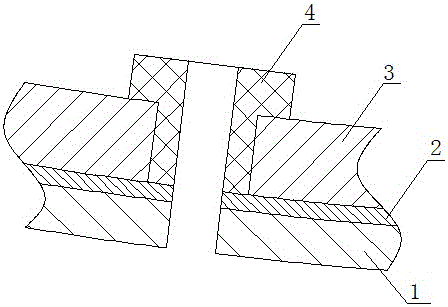

[0045] 1.2 Install the curved surface drilling jig 3 on the outer surface of the skin 2, position and connect the curved surface drilling jig 3 and the skeleton 1 through the positioning pin 5 and fasten them;

[0046] 1.25 Debug and verify the gap between the skin 2 and the skeleton 1, and the gap between the skin 2 and the curved surface drilling mold 3. The tool used for the verification is a feeler gauge, and the feeler gauge is The insertion end is semicircular, the radius R=5mm, and the thickness is 0.6mm.

[0047] 1.3 Install the initial hole drill sleeve 4 in the processing hole 32 provided on the curved surface drilling mold 3; in this step, the inner diameter of the initial hole drill sleeve 4 is φ6mm, and the int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mean radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com