Fruit and vegetable waste collecting and treating mechanism

A technology of fruit and vegetable waste and lifting mechanism, which is applied in grain processing, solid waste removal, organic fertilizer and other directions, can solve the problems of incapable of recycling waste treatment, pollution of soil and water sources, and high investment costs, and achieve recycling of waste. , reduce pollution, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be described in further non-limiting detail below in conjunction with the embodiments and accompanying drawings.

[0025] 1. The basic structure of the fruit and vegetable waste collection and treatment mechanism in this embodiment

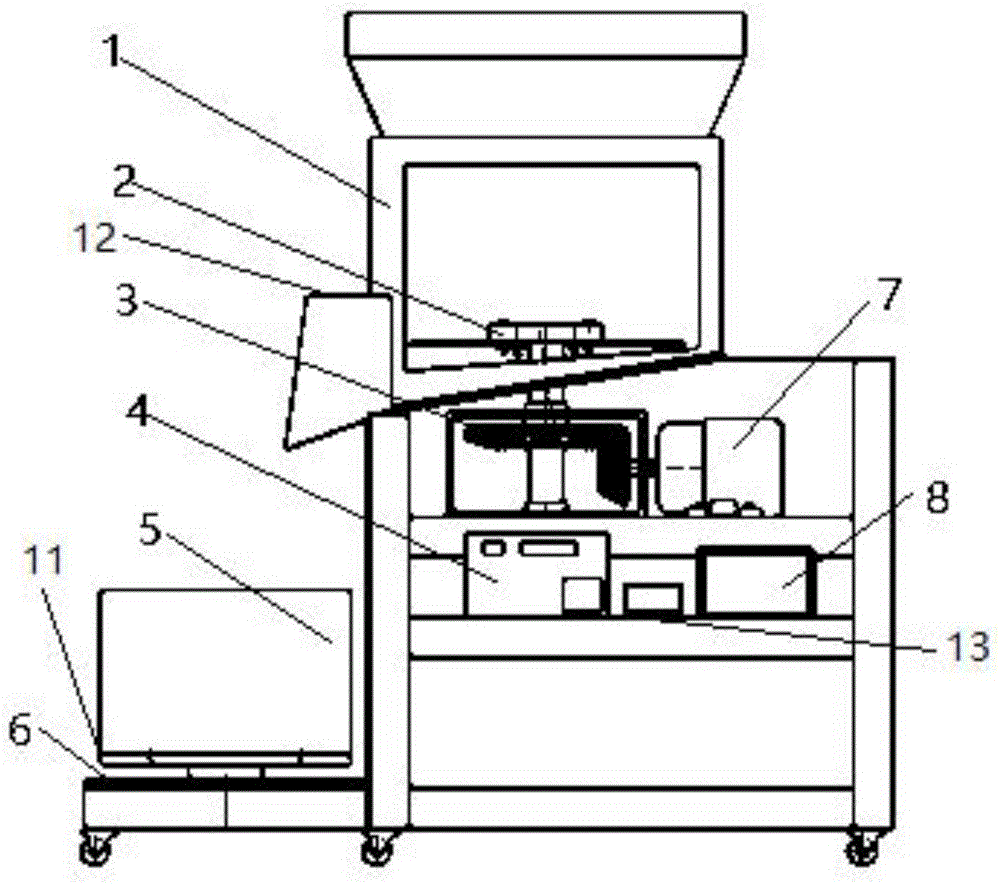

[0026] Such as figure 1 As shown, the fruit and vegetable waste collection and treatment mechanism of this embodiment includes a fermentation container 5, a frame 1 and a chopping mechanism, a weighing mechanism and a lifting mechanism on the mounting frame.

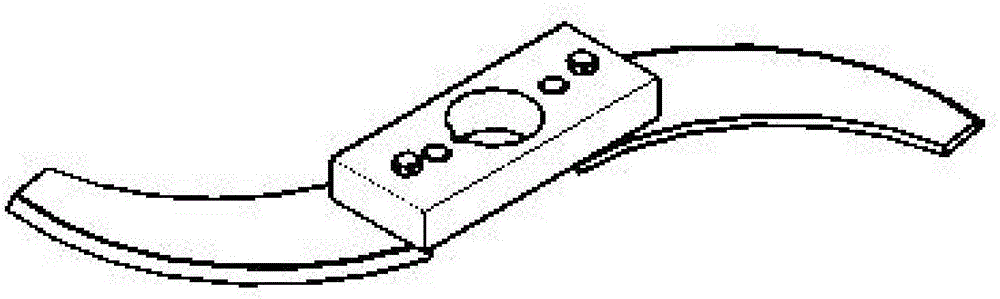

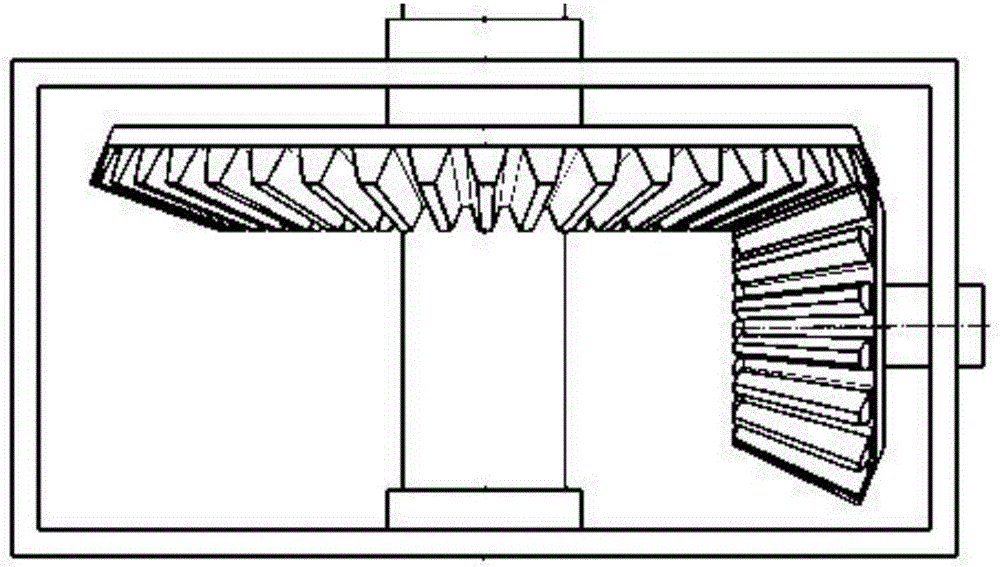

[0027] Described shredding mechanism comprises shredding chamber 12, places the disc cutter 2 in the middle of the shredding chamber, motor 7 and bevel gear set 3 below the shredding chamber, as figure 2 with 3 As shown, the disc cutter 2 is composed of two arc-shaped disc cutters. The motor 7 drives the disc cutter 2 to rotate in the horizontal direction through the bevel gear set 3. Above the chopping chamber 12 is the fruit an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com