Wire lifting device of power transmission line aerial wire

An overhead line and wire lifter technology, applied in the direction of overhead line/cable equipment, etc., can solve the problem of wasting manpower and material resources, and achieve the effect of improving efficiency, improving safety and reliability of use, and saving manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

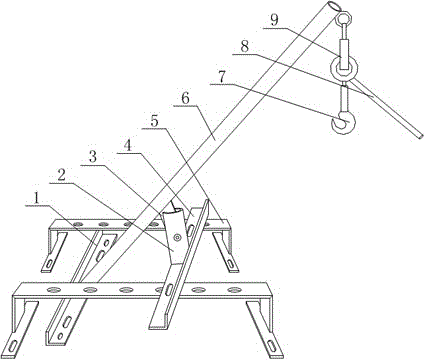

[0021] Such as figure 1 As shown, this embodiment includes a support base 1, a lifting lever 6 is hinged in the middle of the support base 1, and a wire tightener 9 is provided at the end of the lifting lever 6, and a connecting plate 4 and a supporting plate 3 are also included. The middle part of the connecting plate 4 is provided with a support tube 2, one end of the support plate 3 is connected with the lifting lever 6, the other end of the support plate 3 is placed in the support tube 2 and hinged with the support tube 2 through a pin shaft, and along the axis direction of the support tube 2 An opening for the support plate 3 to freely pass is provided on the upper section of its outer wall.

[0022] The specific operation method is as follows: fix the support base 1 and the connecting plate 4 to the appropriate position on the pole or iron tower by bolts, and ensure that there is a distance between the connecting plate 4 and the supporting base 1, so as to satisfy the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com