Multi-train splice angle measurement method based on rear-view binocular camera

A technology of a binocular camera and a measurement method, which is applied in the direction of measurement devices, image data processing, instruments, etc., can solve problems such as sensor failure, and achieve the effects of good real-time performance, low cost, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

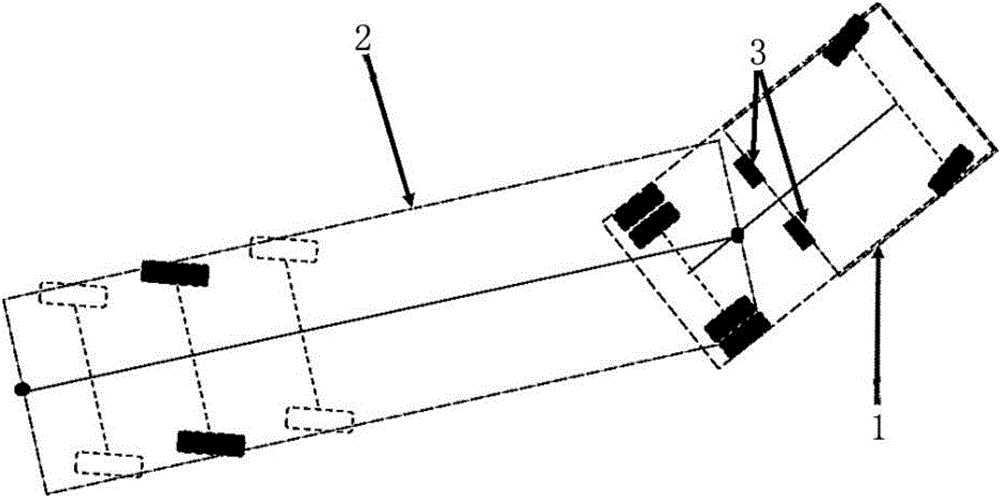

[0036] Embodiment: A kind of multi-train articulation angle measurement method based on the rear-view binocular camera of this embodiment, the flow chart is as follows figure 1 shown. The image of the binocular rear-view camera is the input of the system, and the articulation angle of multi-row container vehicles is the output of the system. The detailed algorithm module functions are introduced as follows:

[0037] 1. Acquire images in binocular RGB format.

[0038] 2. Preprocess the image, mainly including grayscale, distortion removal and binocular alignment.

[0039] 3. Calculate the matching cost based on the sum of absolute differences (SAD), and calculate the final disparity map based on the semi-global optimization (SGBM) method.

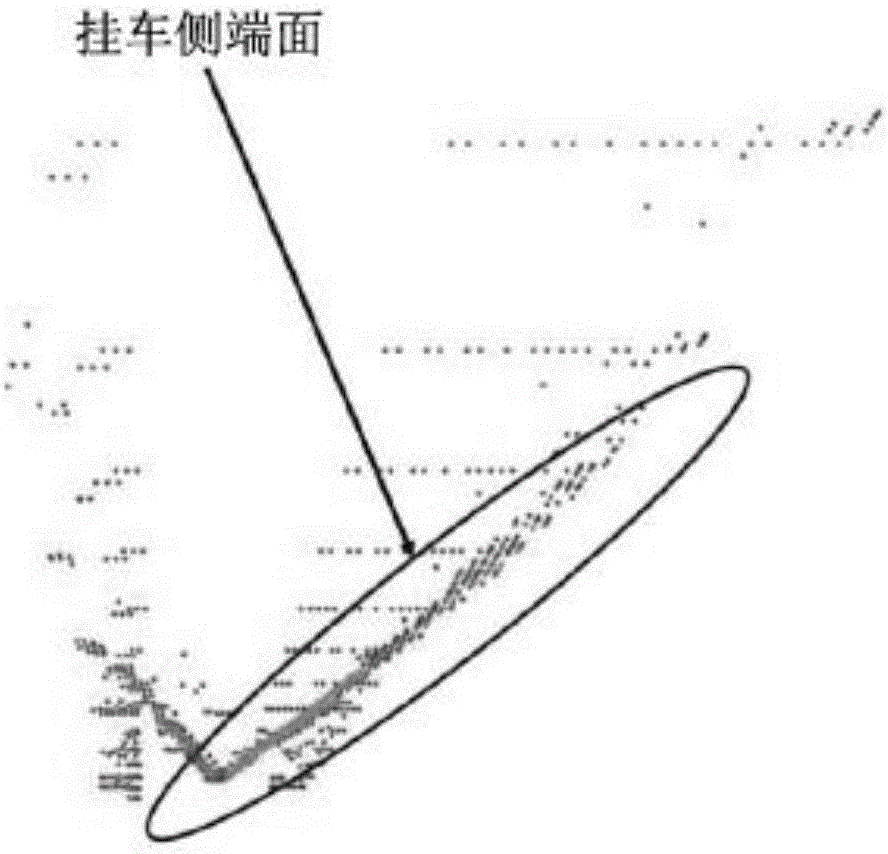

[0040] 4. Use the depth information calculated above to obtain 3D point cloud information. Since the roll and pitch motion of the trailer is relatively small (usually less than 5 degrees), the 3D point cloud can be approximately replaced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com