Dropping wheel type wheel out-of-roundness measurement device and method

A technology of roundness measurement and drop-wheel type, which is applied in the direction of measuring device, railway vehicle shape measuring device, optical device, etc., can solve the problem of high cost, and achieve the effect of convenient portability, high measurement accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

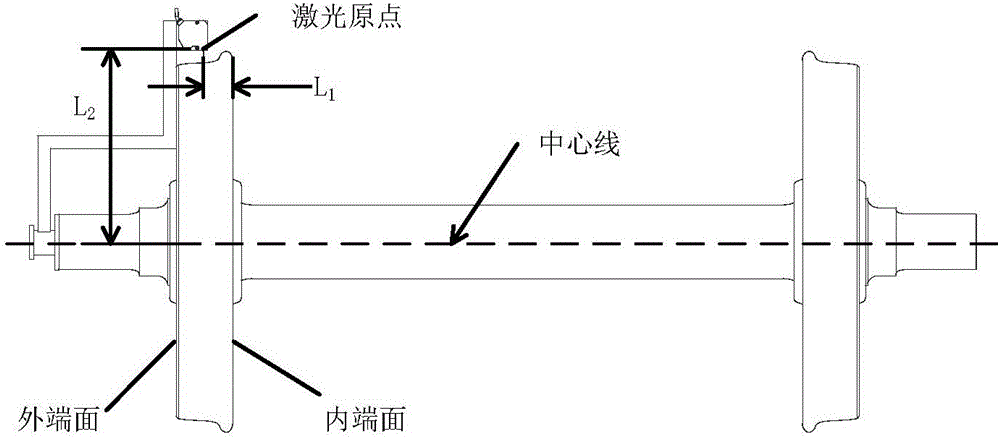

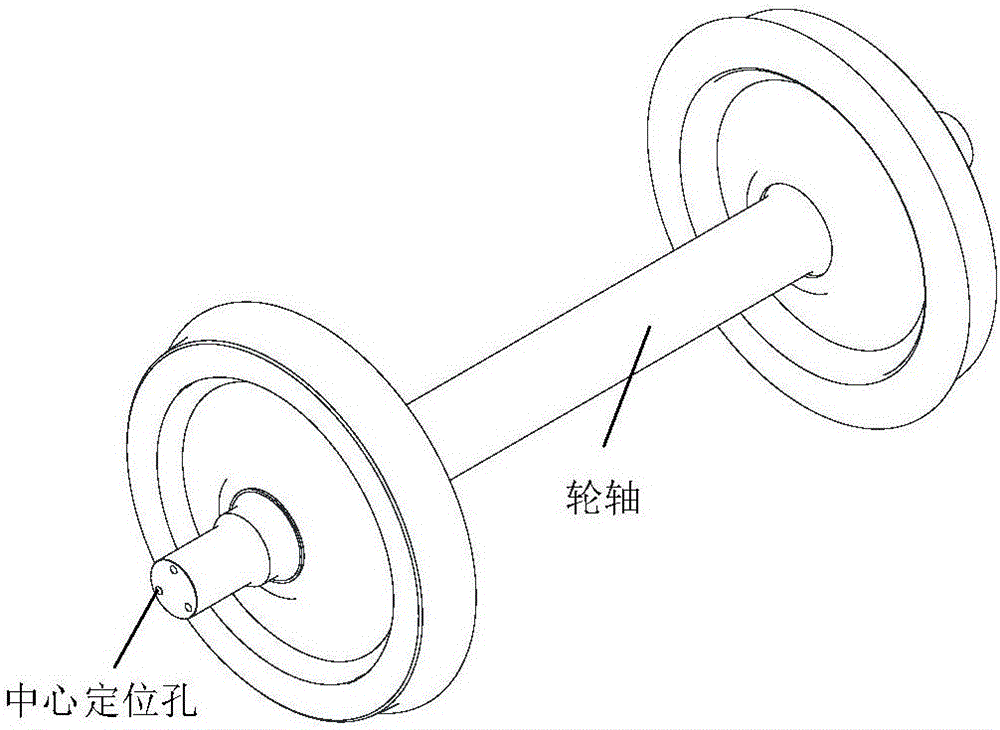

[0059] combine Figure 1~5 In the structure shown, the distance L between the laser origin and the inner end face of the wheel 1 =70mm, this value is a fixed value, according to the definition of the rolling circle of the wheel, the distance L between the center line of the positioning device 1 and the origin of the laser 2 =434mm.

[0060] The sampling frequency of the sensor is set to 50Hz, the wheel rotates once, the sampling points of the sensor are 500, and the raw data output by the sensor y i =[34.302,34.170,34.478...], such as Figure 6 As shown, the actual radius value of the wheel can be calculated, such as Figure 7 shown.

[0061] r i =434-y i

[0062] The wheel rotation angle between every two sampling points of the sensor is:

[0063] θ = 2 π 500

[0064] According to the geometric relationship, the sampling point of the sensor is transformed into the horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com