Back-to-back mounting method and pre-fastening structure of angular contact ball bearings for reducer

A technology for angular contact ball bearings and installation methods, which is applied in the directions of rolling contact bearings, shaft installation, bearing assembly, etc., and can solve the problems of difficult assembly of bearings that meet the requirements of use, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

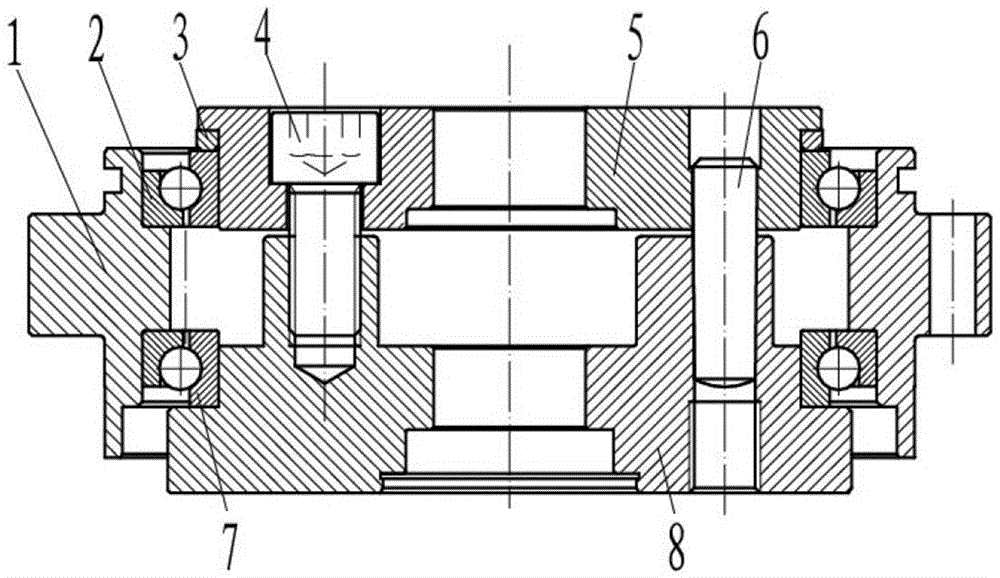

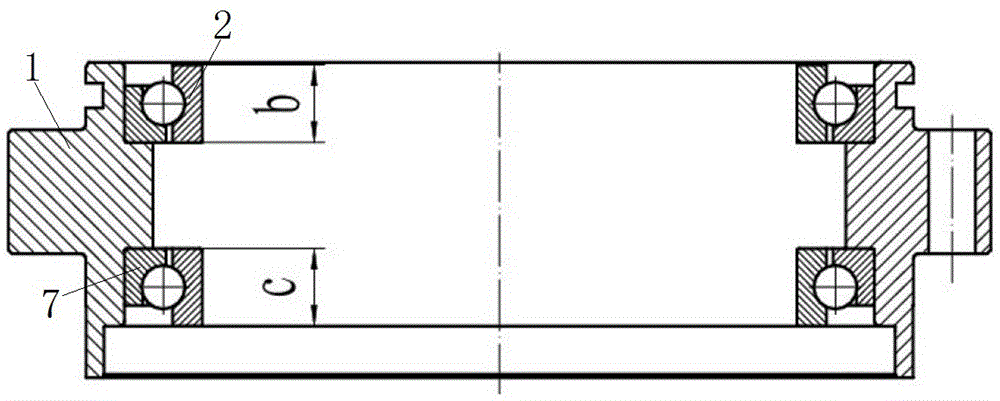

[0018] The specific embodiment of the back-to-back angular contact ball bearing preload structure for the reducer of the present invention is as follows: Figure 1 to Figure 5 As shown, it includes a reducer housing 1 with an inner cavity whose axis extends along the front-to-back direction in the middle. The contact ball bearing 7 is also provided with a support flange for cooperating with the reducer housing to fix the above two bearings in the inner cavity. The wide side faces of the outer rings of the two bearings are arranged opposite to each other so that the load line of the two bearings is formed in an "O" shape and assembled back to back.

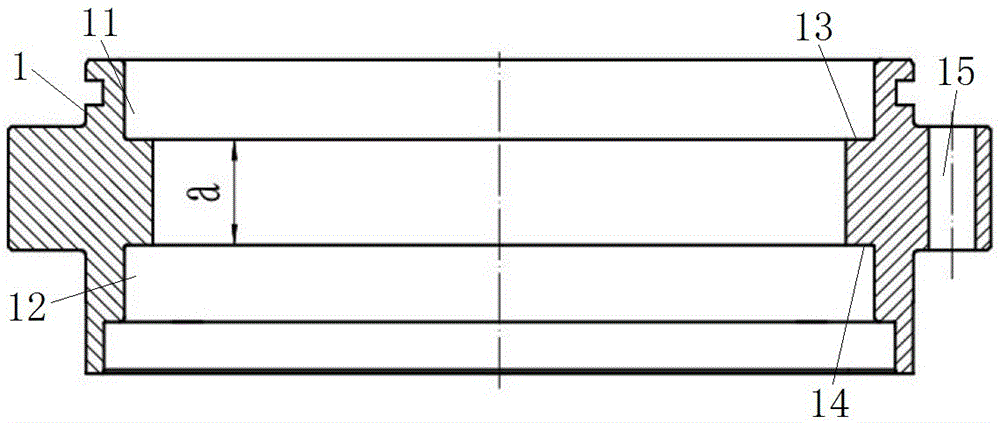

[0019] The front end of the reducer housing 1 is provided with a first concave cavity 11 along its inner wall surface, and the rear end of the reducer housing 1 is provided with a second concave cavity 12 al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com