Top end sealing and lubricating device of rotary engine

A technology of rotor engine and lubricating device, which is applied to the sealing device of the engine, the lubrication of the engine, the lubricant conduit device, etc. It can solve the deterioration of the seal between the top sealing plate and the cylinder surface, and the problem of lubrication is not well solved. Three Cavities cannot be completely separated to achieve the effects of reducing carbon deposits, increasing cylinder pressure, and preventing dry grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

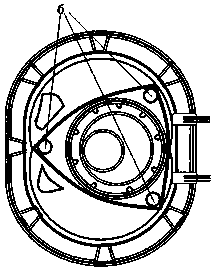

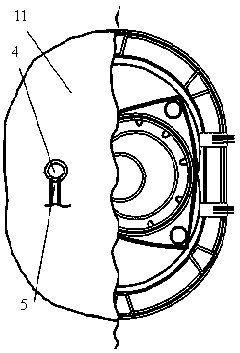

[0022] as attached Figure 1-4 The top sealing and lubricating device of a rotary engine is shown, at least consisting of a high-pressure lubricating oil pump 1, an oil delivery pipe 2, a high-pressure nozzle 3, a lubricating oil spray hole 4, an oil return pipe 5, an axial oil pipe 6, a radial oil pipe 7, and a top sealing plate 8. The corner sealing strip 9, the top sealing groove 10 and the side shell 11 are composed; the lubricating oil injection hole 4 is opened on the side shell 11 near the exhaust port of the engine, and the high-pressure nozzle 3 is installed in the lubricating oil injection hole 4; There is an oil return port in the hole 4, and the oil return port is connected with the oil return pipe 5. When the injected lubricating oil fills the axial oil pipe 6 or is blocked by the end face of the rotor due to an accident, the lubr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com