Electric pump well temporary plugging and drainage integrated self-lifting casing and fishing free device

A technology that avoids fishing and electric pumps. It is applied in the direction of wellbore/well valve devices, wellbore/well parts, earthwork drilling and production, etc. It can solve the problem of unconnected, long construction time, and inability to perform positive circulation washing of the completion string. Well work and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention provides an integrated self-lifting and fishing-free device for temporary blockage and discharge of an electric pump well. After using the integrated device, the pressure test of the pipe string can be completed during the downhole process; After the packer is turned on for test pumping, the set valve stem assembly can be taken out through the wax removal valve of the Christmas tree, so as to quickly complete the pre-production preparation. If positive and negative well flushing is to be performed during the production process, it is only necessary to put the setting valve stem assembly into positive pressure from the wax removal valve.

[0016] Embodiments of the present invention will be described in detail below in conjunction with the following drawings.

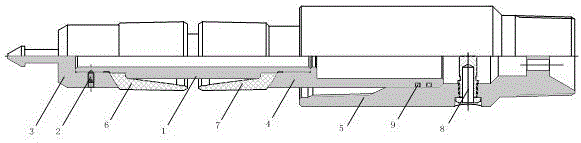

[0017] The invention provides a self-lifting and fishing-free device for temporary blockage and discharge of an electric pump well, such as figure 1 As mentioned above, the setting valve stem assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com