External wall subsidence post-cast strip closing method and external wall subsidence post-cast strip closing device

A technology of closing device and post-casting belt, which is applied in protection devices, water conservancy projects, artificial islands, etc., can solve the problems of high height, collapse, and setting bolts in the post-casting belt, and achieve the effect of simple construction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The core of the present invention is to provide a sealing method and device for pouring strips after the outer wall has settled, which has a simple construction process and can bear greater lateral pressure.

[0033] In order to enable those skilled in the art to better understand the technical solution of the present invention, the method and device for sealing the casting tape after the outer wall subsidence of the present application will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

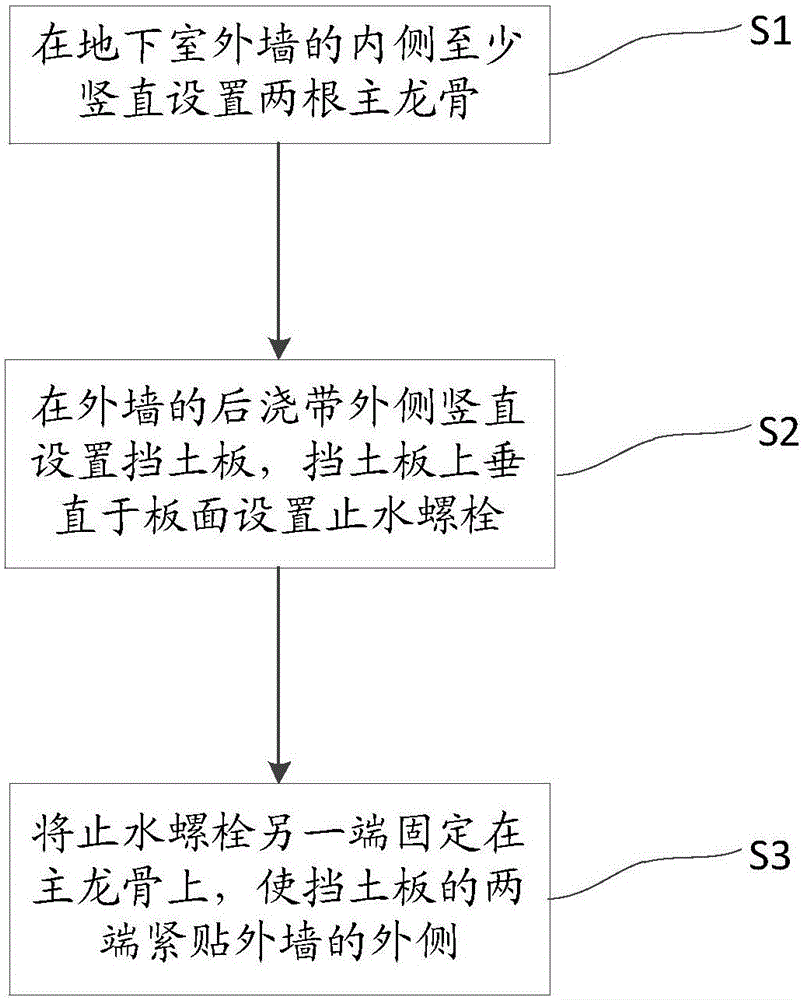

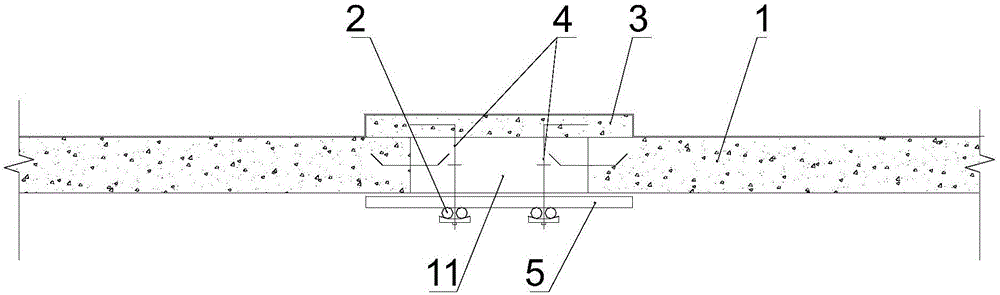

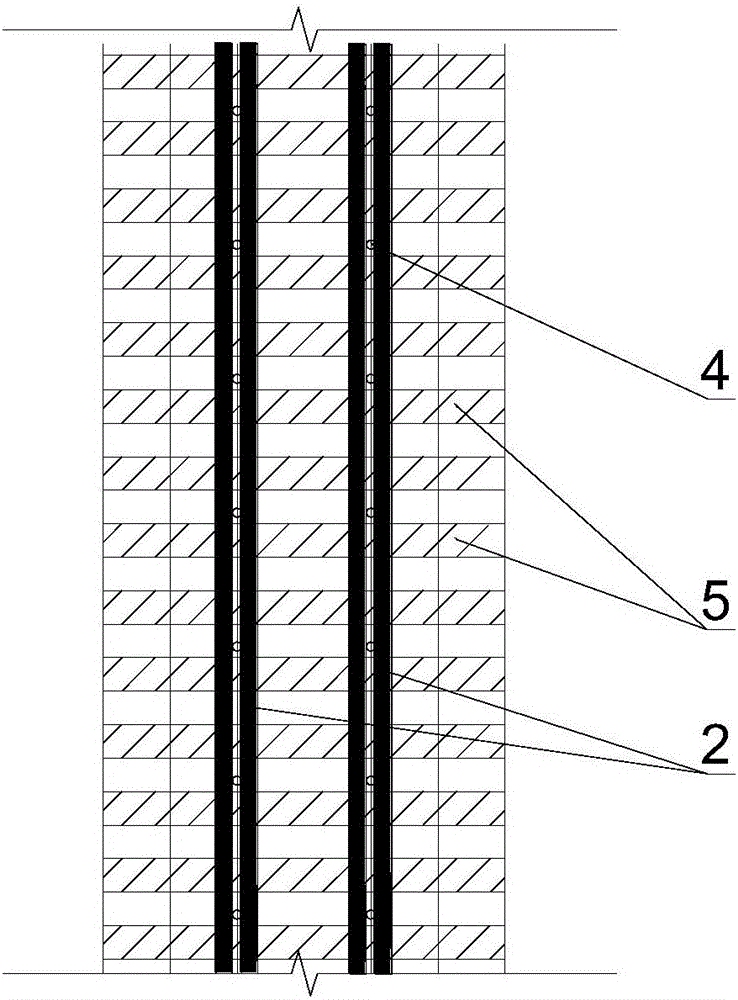

[0034] Such as figure 1 As shown, the present invention provides a flow chart of a method for sealing the poured tape after the outer wall settles. The method at least includes the following steps: S1, at least two main keels 2 are vertically arranged on the inner side of the basement exterior wall 1; Set the water-stop bolt 4 perpendicular to the board surface; S3, fix the other end of the water-stop bolt 4 on the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com