Construction method for open excavation assembly monolithic structure subway station using pile-strut bracing system

A construction method and integrated technology, applied in infrastructure engineering, excavation, underwater structures, etc., can solve the problems of high demand for construction turnover materials, high demand for on-site labor, low degree of engineering mechanization, etc., to reduce the impact on the surrounding environment , Improve the overall construction quality and improve the effect of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

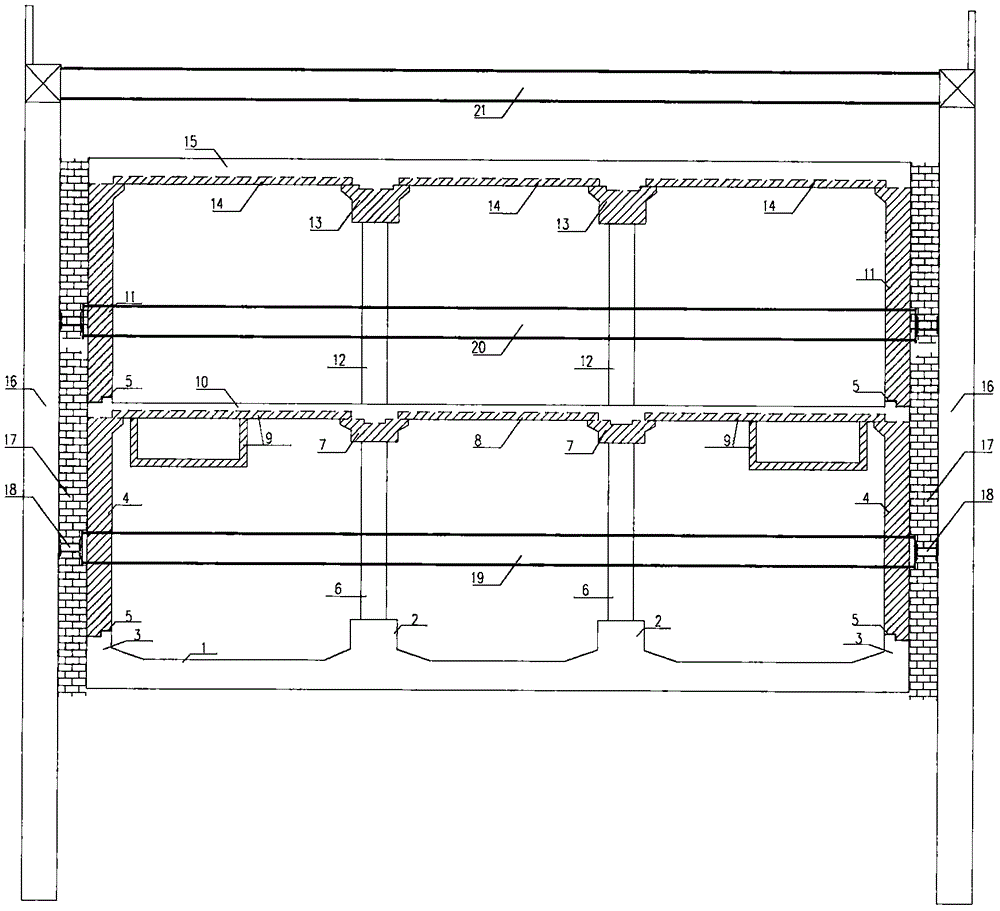

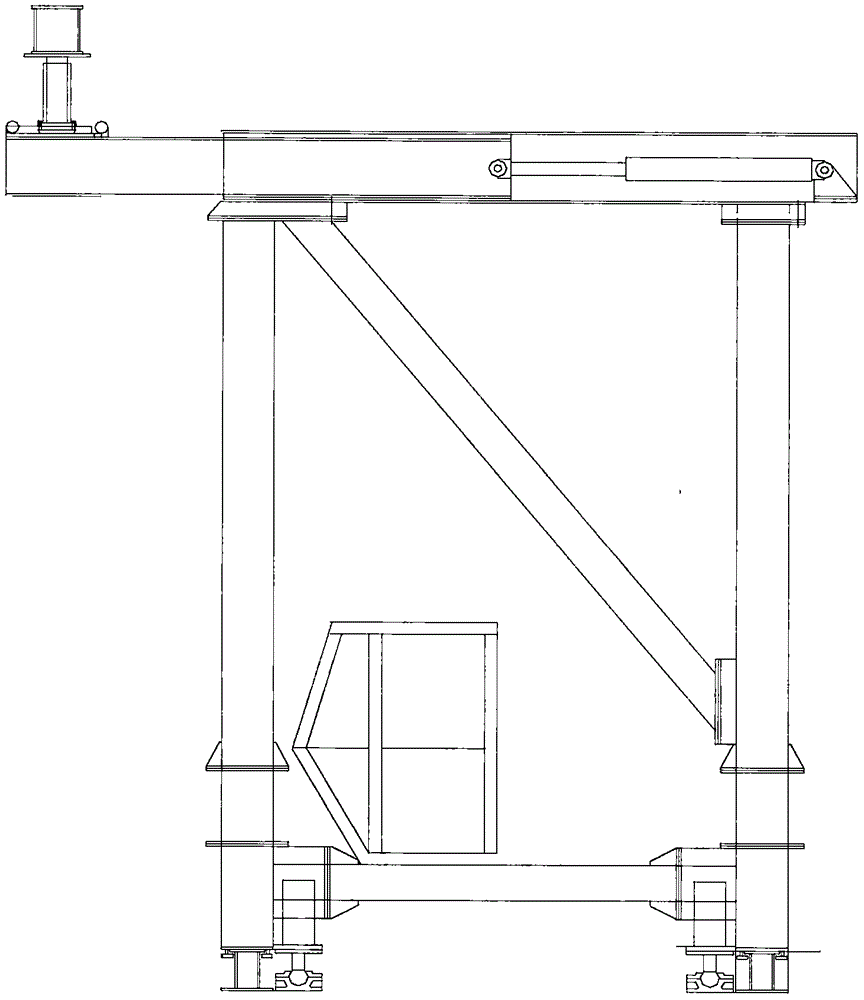

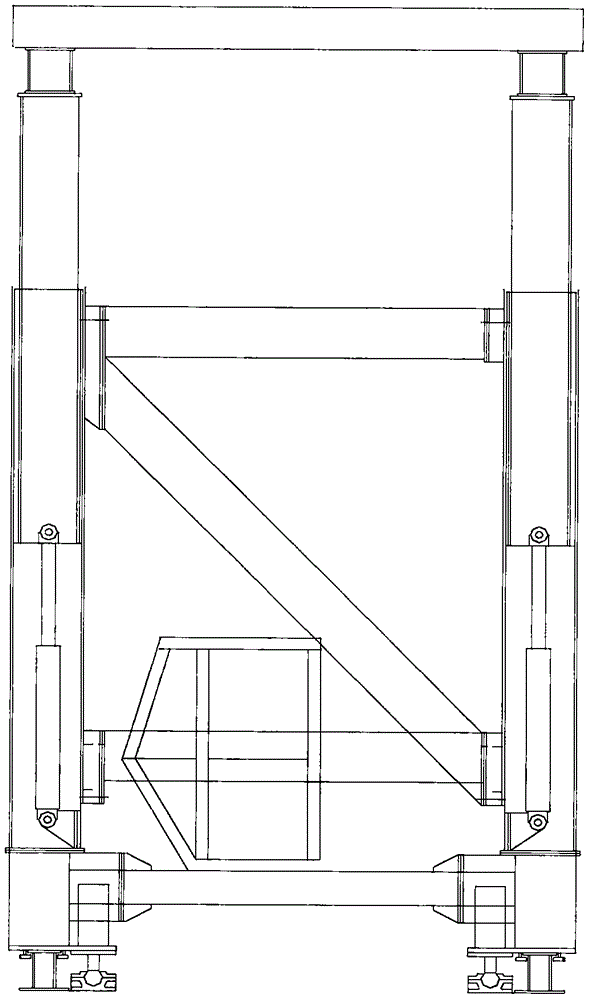

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0028] The construction method of an open-cut assembly integrated structure subway station using a pile support system includes the following steps:

[0029]1. After the excavation and support of the foundation pit of the open-cut assembly integrated structure of the pile support system is completed, three horizontal steel supports are set from top to bottom, the structural floor is cast-in-place, and the structural side walls are divided into B2 floors The prefabricated side wall and the prefabricated side wall on the B1 floor, the prefabricated side wall components are embedded with semi-grouting sleeves at the bottom of the prefabricated side wall components and are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com