Method for producing crystal malt with aromatic flavor

A production method and malt technology are applied in the production field of crystalline malt with rich aroma, which can solve the problems of pasty skin, rough bitterness, and pasty skin, etc., and achieve the effect of rich caramel sweetness and rich malt aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

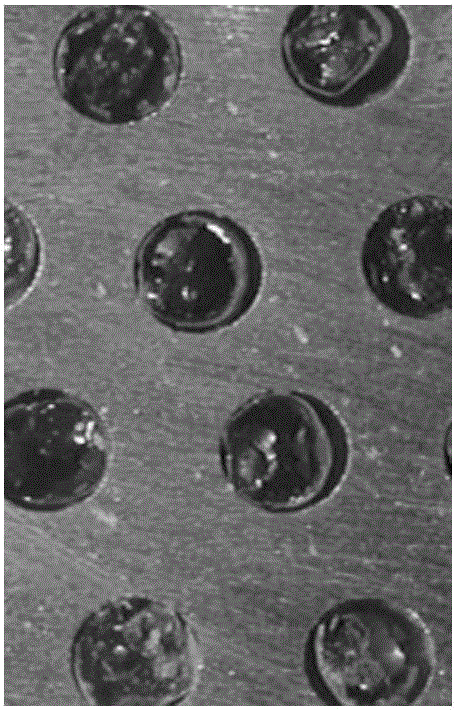

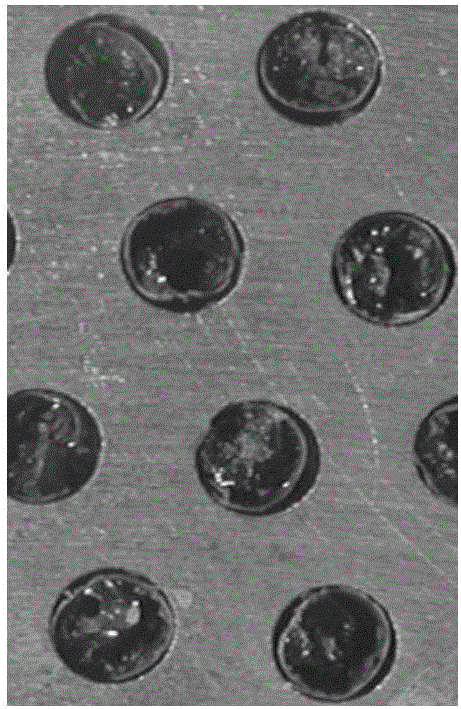

Image

Examples

Embodiment 1

[0031] The green malt is obtained by using high-quality French imported two-row barley as raw material and germinating according to conventional techniques. The physical and chemical indicators of two-row barley are shown in Table 1 below:

[0032] Table 1

[0033]

[0034] The method for producing crystalline malt by adopting green malt, the steps are as follows:

[0035] 1. Protein rest: select green malt that has been fully dissolved after germination and has a moisture content of 42%, put it in a roasting converter, slowly heat it up to 48°C at a heating rate of 1°C / min, and keep it for 1 hour, and protein will be produced inside the malt Rest, carboxypeptidase, endopeptidase, etc. decompose protein to generate low-molecular nitrogen-containing substances;

[0036] 2. Saccharification: heat up to 68°C at a heating rate of 0.5°C / min, keep it for 1 hour, use the internal enzyme system of malt to carry out saccharification, the α-amylase and β-amylase in the malt will fu...

Embodiment 2

[0048] The method for producing crystallized malt using green malt shown in Example 1, the difference is:

[0049] Step 1. Protein rest: After germination, green malt that has been fully dissolved and has a moisture content of 43% is selected, placed in a roasting converter, and slowly heated to 49°C at a heating rate of 1°C / min, and kept for 1 hour;

[0050] Step 3, dehumidification; after saccharification, heat up to 96°C, keep warm for 2 minutes, quickly cool down to 69°C, then raise the temperature to 96°C, keep warm for 2 minutes, repeat the above dehumidification steps 3 times;

Embodiment 3

[0052] The method for producing crystallized malt using green malt shown in Example 1, the difference is:

[0053] Step 1. Protein rest: select green malt that has been fully dissolved after germination and has a water content of 45%, put it in a coke converter, and slowly heat it up to 50°C at a heating rate of 1°C / min, and keep it for 1h;

[0054] Step 3. Dehumidification; after saccharification, heat up to 92°C, keep warm for 2 minutes, cool down to 70°C, then raise the temperature to 92°C, keep warm for 2 minutes, and repeat the above moisture removal steps 3 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com