Method for preparing phenylamino porphyrin self-assembled nanomaterial by adopting co-solvent method

A technology of anilinoporphyrin and nanomaterials, which is applied in the field of preparing anilinoporphyrin self-assembled nanomaterials, can solve problems such as high cost, limited solubility, and low product yield, and achieve low equipment requirements, regular appearance, and low cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of method adopting co-solvent method to prepare anilinoporphyrin self-assembled nanometer material comprises the following steps:

[0029] (1) Dissolve CTAB (purity 99%) in water to prepare 0.01 M CTAB solution;

[0030] (2) Anilinoporphyrin is dissolved in DMF to make a DMF solution of 0.01 M anilinoporphyrin;

[0031] (3) Quickly inject 0.1 mL of the solution prepared in step (2) into 1.9 mL of the solution prepared in step (1), stir at 25°C for 48 h, centrifuge at 10,000 r for 15 min, discard the supernatant, and collect the precipitate to obtain Anilinoporphyrin self-assembled nanomaterials.

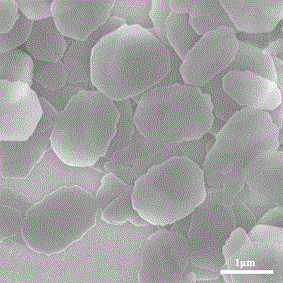

[0032] SEM images of sheet-like anilinoporphyrin self-assembled nanomaterials figure 1 As shown, it can be seen that the sheet-like assembly has a regular shape, jagged edges, a length of about 1.5 μm, and a width of 580 nm-1.3 μm.

Embodiment 2

[0034] A kind of method that adopts co-solvent method to prepare anilinoporphyrin self-assembled nanometer material, the difference with embodiment 1 is: use SDS instead as emulsifier, specifically comprise the following steps:

[0035] (1) Dissolve SDS (purity 99%) in water to make a 0.01 M SDS solution;

[0036] (2) Anilinoporphyrin is dissolved in the DMF solution to make a DMF solution of 0.01 M anilinoporphyrin;

[0037] (3) Quickly inject 0.1 mL of the solution prepared in step (2) into 1.9 mL of the solution prepared in step (1), stir at 25°C for 48 h, centrifuge at 10,000 r for 15 min, discard the supernatant, and collect the precipitate to obtain Anilinoporphyrin self-assembled nanomaterials.

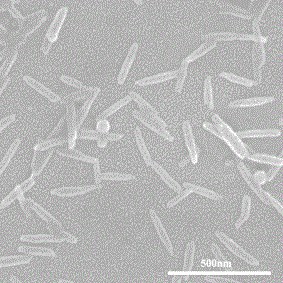

[0038] SEM images of rod-like anilinoporphyrin self-assembled nanomaterials figure 2 As shown, it can be seen that the assembly length of the rod-like structure is uniform, and the length is about 197 nm. The nanorod-like anilinoporphyrin material was tested for visible lig...

Embodiment 3

[0040] A kind of method that adopts co-solvent method to prepare anilinoporphyrin self-assembled nanomaterials, the difference with embodiment 1 is: use MTAB instead as emulsifier, specifically comprise the following steps:

[0041] (1) Dissolve MTAB (purity 99%) in water to make 0.01 M MTAB solution;

[0042](2) Anilinoporphyrin is dissolved in the DMF solution to make a DMF solution of 0.01 M anilinoporphyrin;

[0043] (3) Quickly inject 0.1 mL of the solution prepared in step (2) into 1.9 mL of the solution prepared in step (1), stir at 25°C for 48 h, centrifuge at 10,000 r for 15 min, discard the supernatant, and collect the precipitate to obtain Anilinoporphyrin self-assembled nanomaterials.

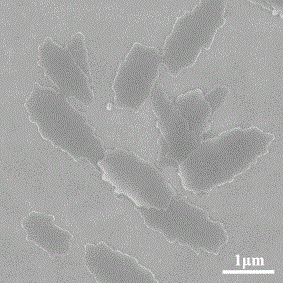

[0044] SEM images of sheet-like anilinoporphyrin self-assembled nanomaterials image 3 As shown in , the morphology is regular and jagged fusiform with a length of 1.3-2 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com