Desulfurization ash-coal ash complex mineral admixture and preparation method thereof

A composite mineral and fly ash technology, which is applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of insufficient understanding of the utilization potential of mixed desulfurization ash and fly ash, and achieve increased Compactness, strength promotion, and strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

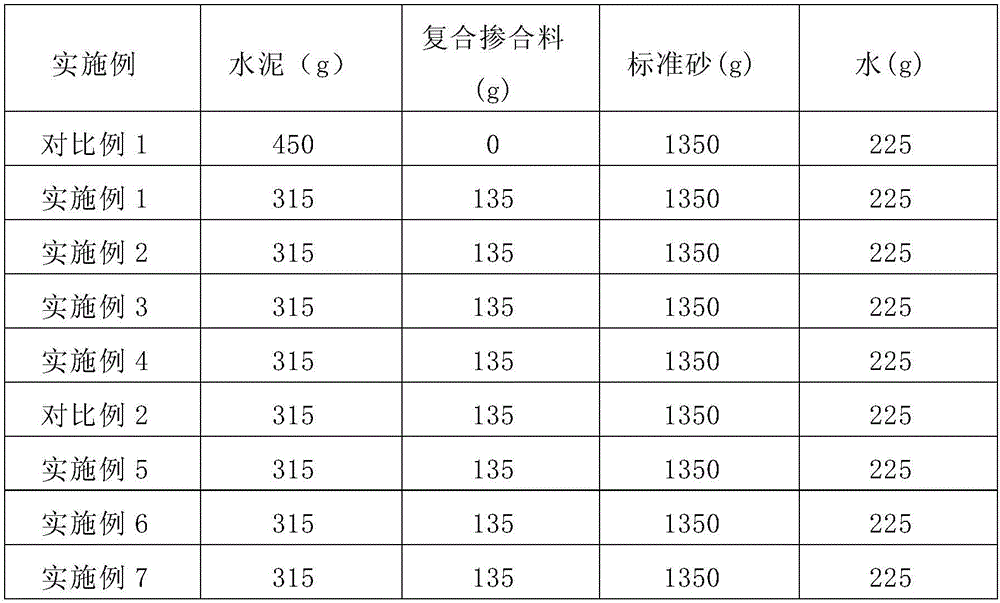

[0031] Preparation of desulfurization ash-fly ash composite mineral admixture: take the following raw materials by mass percentage: 40 parts of desulfurization ash, 52 parts of fly ash, 8 parts of enhanced activation materials (CaO, SiO 2 、Al 2 o 3 , Fe 2 o 3 , SO 3 According to the mass ratio of 63:25:7:3:2, the specific surface area is 6100cm 2 / g, the activity index is 150%) surface modifiers and grinding aids account for 0.3% and 0.2% of the sum of desulfurization ash, fly ash, and enhanced activation materials, respectively.

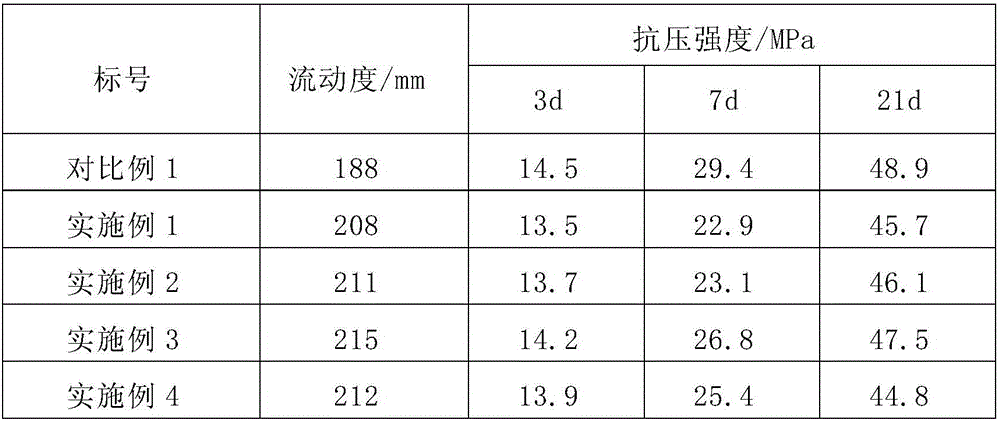

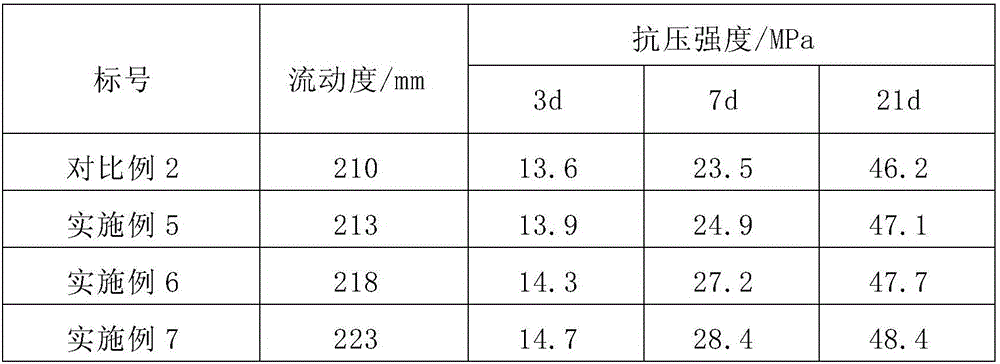

[0032] Put the above-mentioned raw materials into a ball mill, and grind them until the screening amount of a 45 μm square hole sieve is less than 10%, dry the ground materials at about 100°C, and mix them evenly in a V-type mixer after cooling to obtain modified desulfurization Ash-fly ash concrete composite mineral admixture. Apply the obtained composite mineral admixture to cement mortar (see Table 1 for specific proportions), replace 30% o...

Embodiment 2

[0034] Preparation of desulfurization ash-fly ash composite mineral admixture: take the following raw materials by mass percentage: 50 parts of desulfurization ash, 42 parts of fly ash, 8 parts of enhanced activation materials (CaO, SiO 2 、Al 2 o 3 , Fe 2 o 3 , SO 3 According to the mass ratio of 63:25:7:3:2, the specific surface area is 6100cm 2 / g, the activity index is 150%) surface modifiers and grinding aids account for 0.3% and 0.2% of the sum of desulfurization ash, fly ash, and enhanced activation materials, respectively.

[0035]Put the above-mentioned raw materials into a ball mill, and grind them until the screening amount of a 45 μm square hole sieve is less than 10%, dry the ground materials at about 100°C, and mix them evenly in a V-type mixer after cooling to obtain modified desulfurization Ash-fly ash concrete composite mineral admixture. The gained composite mineral admixture is applied in cement mortar (concrete proportioning is shown in Table 1), adopt...

Embodiment 3

[0037] Preparation of desulfurization ash-fly ash composite mineral admixture: take the following raw materials by mass percentage: 60 parts of desulfurization ash, 32 parts of fly ash, 8 parts of enhanced activation materials (CaO, SiO 2 、Al 2 o 3 , Fe 2 o 3 , SO 3 According to the mass ratio of 63:25:7:3:2, the specific surface area is 6100cm 2 / g, the activity index is 150%) surface modifiers and grinding aids account for 0.3% and 0.2% of the sum of desulfurization ash, fly ash, and enhanced activation materials, respectively.

[0038] Put the above-mentioned raw materials into a ball mill, and grind them until the screening amount of a 45 μm square hole sieve is less than 10%, dry the ground materials at about 100°C, and mix them evenly in a V-type mixer after cooling to obtain modified desulfurization Ash-fly ash concrete composite mineral admixture. The obtained composite mineral admixture is applied in cement mortar (see Table 1 for the specific proportion), and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com