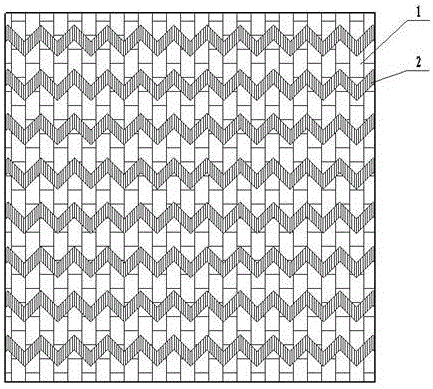

Cross-waved fabric with interconnected unit coils

A unit coil and wavy pattern technology, which is applied in the field of fabrics and textile fabrics, can solve the problems of poor cold protection, no three-dimensional effect, and unsatisfactory effects, and achieve the effect of reasonable structure, enhanced three-dimensional effect and hand feeling, and good softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The object of the present invention is achieved in the following way: a fabric with unit coils interspersed with cross waves, including a fabric body 1, the outer surface of the fabric body 1 is provided with a number of protrusions 2, the protrusions 2 are wavy, The protrusions 2 are connected to the fabric body 1 as a whole, and the protrusions 2 and the fabric body 1 are inclined at an angle of 90 degrees and arranged in parallel.

[0014] The fabric body 1 is woven from warp and weft threads, jute fibers are used for the warps, and polyvinyl chloride fibers are used for the weft threads, wherein the diameter of the jute fibers is 21.76 μm, and the fineness is 253 dtex, and the diameter of the polyvinyl chloride fibers is 45.71 μm, and the fineness is 573 dtex , the warp density is 23.8 threads / cm, and the weft density is 54.8 threads / cm.

[0015] The inner surface of the fabric body is provided with a lining fabric layer, and the lining fabric layer is a kind of kni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com