Napping fabric with good rigidity and hardness

A fabric and hardness technology, which is applied in the field of textile fabrics and fabrics, can solve the problems of no three-dimensional effect, limited application range, single color of the cloth surface, etc., and achieve the effect of increasing stiffness and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

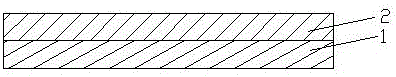

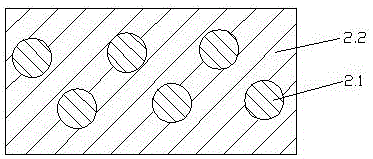

[0015] see figure 1 and figure 2 , The present invention relates to a brushed fabric with good stiffness and hardness, comprising a fabric body 1, the surface of the fabric body 1 has a pile layer 2, and the pile layer 2 includes a pattern area 2.1 and a non-pattern area 2.2. The direction of the fluff in the pattern area 2.1 and the non-pattern area 2.2 is reversed by means of hot pressing, so as to highlight the three-dimensional effect of the pattern in the pattern area 2.1, which is full of fashion.

[0016] A lining fabric layer is provided on the back of the fabric body, and the lining fabric layer is made of braided fabric, and the braided fabric may include a plurality of warp threads and at least one weft thread coupled with the plurality of warp threads. The braid may also include a plurality of bonding fibers. The joining fibers may be positioned parallel to the warp threads and / or parallel to the weft threads. In addition, the bonding fibers may be formed from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com