Modularized control system of carbon fiber winding tension

A modular control and fiber tension technology, applied in the field of electromechanical control, can solve problems such as limited control range, low control precision, and large gap, and achieve the effect of simple monitoring and adjustment operations, high precision of tension control, and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

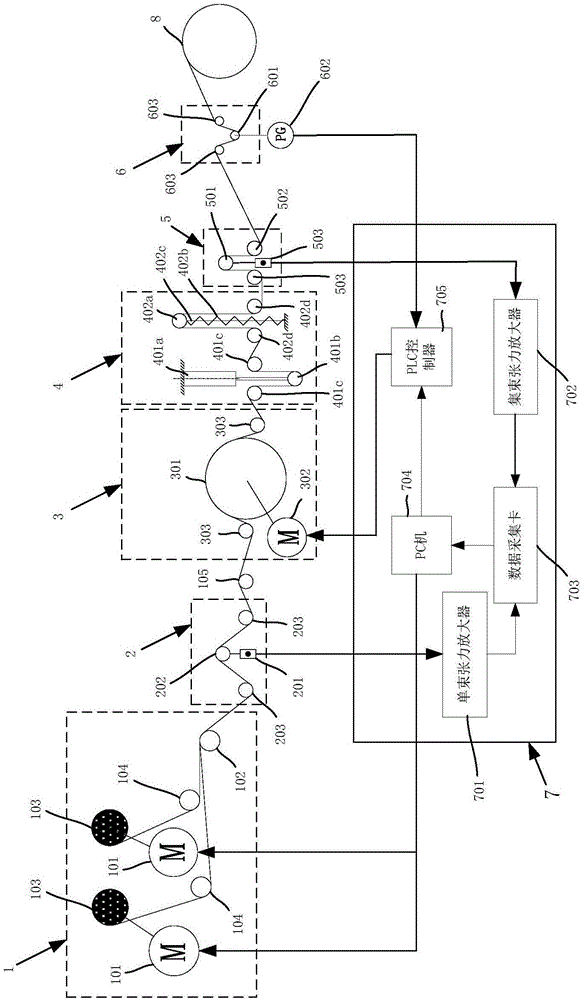

[0049] The invention is a carbon fiber winding tension modular control system, which has a modular mechanical body and a console. Among them, the mechanical body includes an unwinding module 1 , a single-bundle fiber tension detection module 2 , an active speed regulation module 3 , a buffer module 4 , a bundle tension detection module 5 and a speed measurement module 6 installed on the frame.

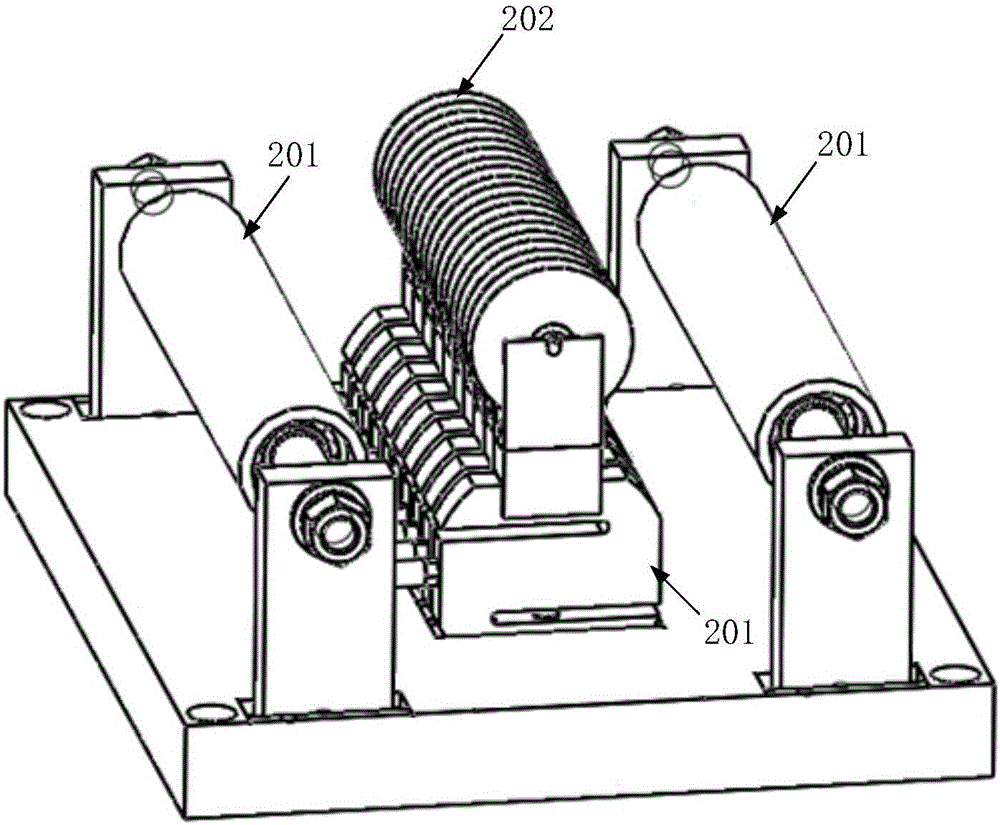

[0050] The above-mentioned unwinding module 1 includes a direct drive rotating motor 101 , a fiber conduction wheel 102 , an unwinding bobbin 103 and an unwinding conduction roller 104 . The unwinding spool 103, the unwinding guide roller 104 are arranged parallel to the axis of the fiber guide wheel 102, and are installed on both sides of the frame from front to back. Wherein, the unwinding spool 103 is covered with a fiber yarn roll, and the fiber bypasses th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com