Casting bottom pouring system and design method

A technology of bottom pouring and design method, which is applied in casting molding equipment, casting molds, casting mold components, etc., can solve the problems of increasing the difficulty of manufacturing, increasing the manufacturing cost of casting products, and increasing the cost of casting products, so as to reduce the filling time and stabilize the filling time. Type, fast pouring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

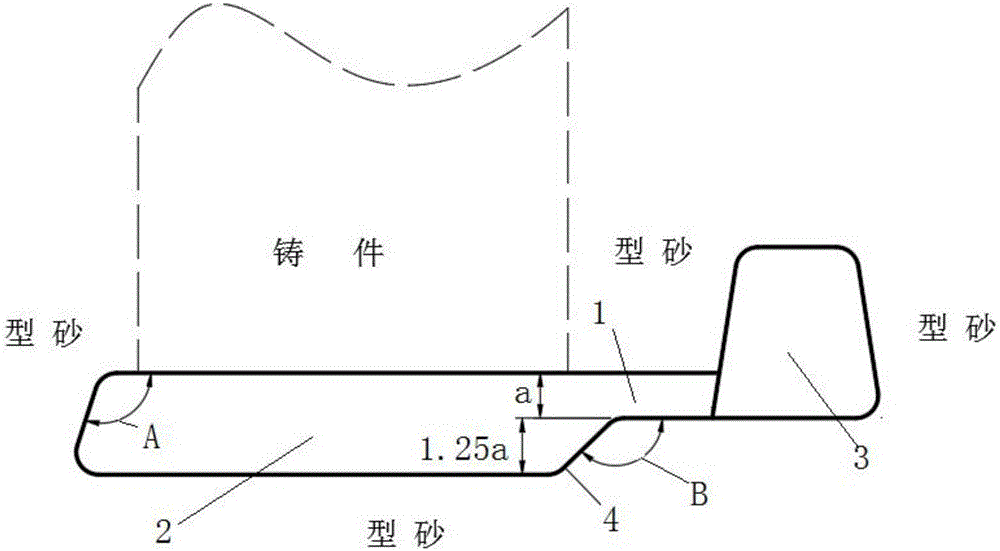

Method used

Image

Examples

Embodiment 1

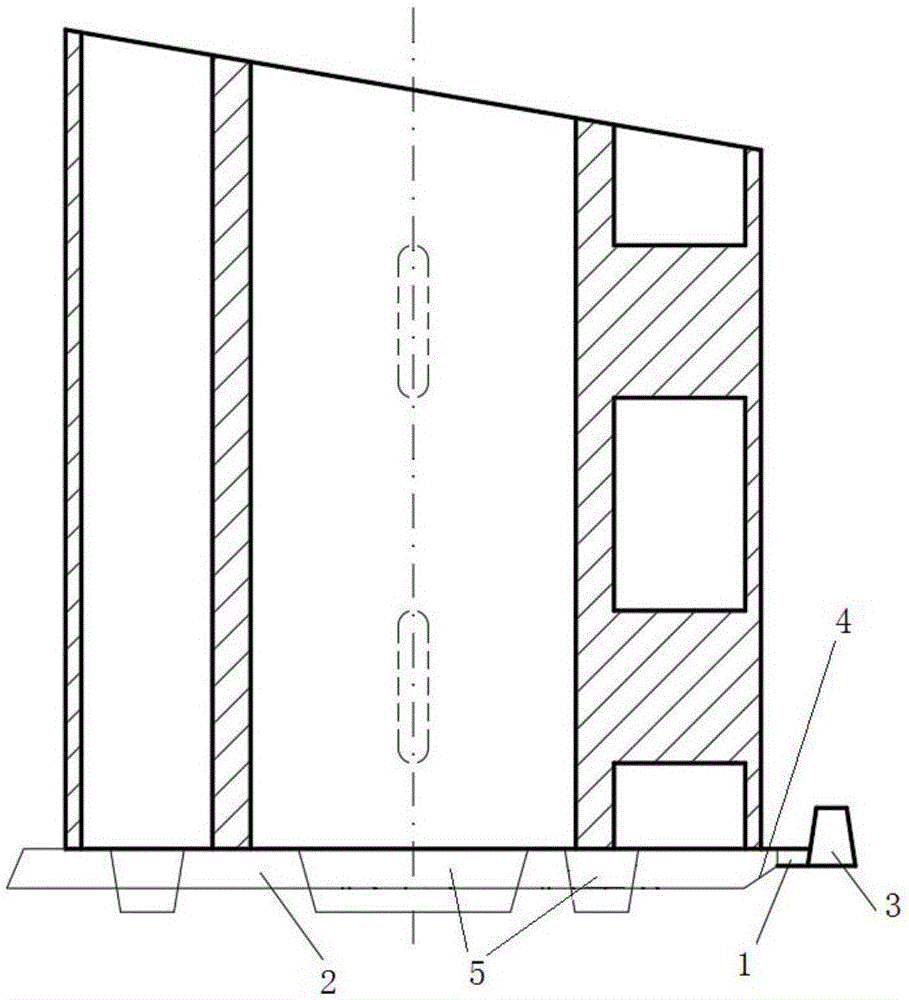

[0030] Such as image 3 and 4 As shown, it is a pouring schematic diagram of a certain stainless steel condenser tube. The structure of the casting workpiece seems not complicated, but the diameter is large (760mm), the height is high (900mm), the tube wall is thick and thin, and there are thin walls in the clamping wall. For ribs, the technological requirement is to enter water at multiple points. If the gating system is designed according to the routine, it is not only complicated, but also brings great difficulty to the shape. The pouring system designed by using the bottom pouring method of the present invention has a simple shape and can meet technological requirements.

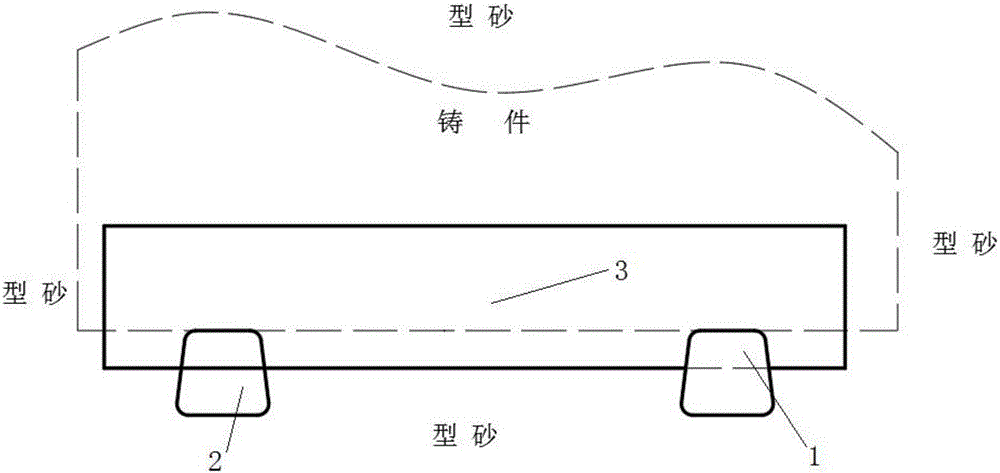

[0031] Such as Figure 4 , the water inlet 2 of the bottom pouring system is a composite type of straight water inlet and arc water inlet, which consists of 1 runner 3, 4 ingates 1, 2 straight water inlets 2, and 2 arc water inlets 2 Composition, 6 water inlets are set at the thin wall and 4 water inl...

Embodiment 2

[0033] Such as Figure 5 and 6 As shown, it is a casting schematic diagram of a stainless steel pump volute. The casting has many bends and is of a volute shape. According to the conventional process, the casting will produce casting defects of different sizes on the neck of the water inlet. There are two conventional techniques, one is to open 3 to 4 ingates 1 for water intake from the volute wall; the other is to open a rain pouring system from the bottom flange. The first is simple, but not very effective; the second is complex, but also has defects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com