Automatic plate cleaning system

A technology for automatic cleaning and cleaning of boards, applied in cleaning methods and tools, cleaning methods using tools, textiles and papermaking, etc., can solve problems such as safety, low production efficiency, hidden dangers, etc., achieve long service life, simple structure, Easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

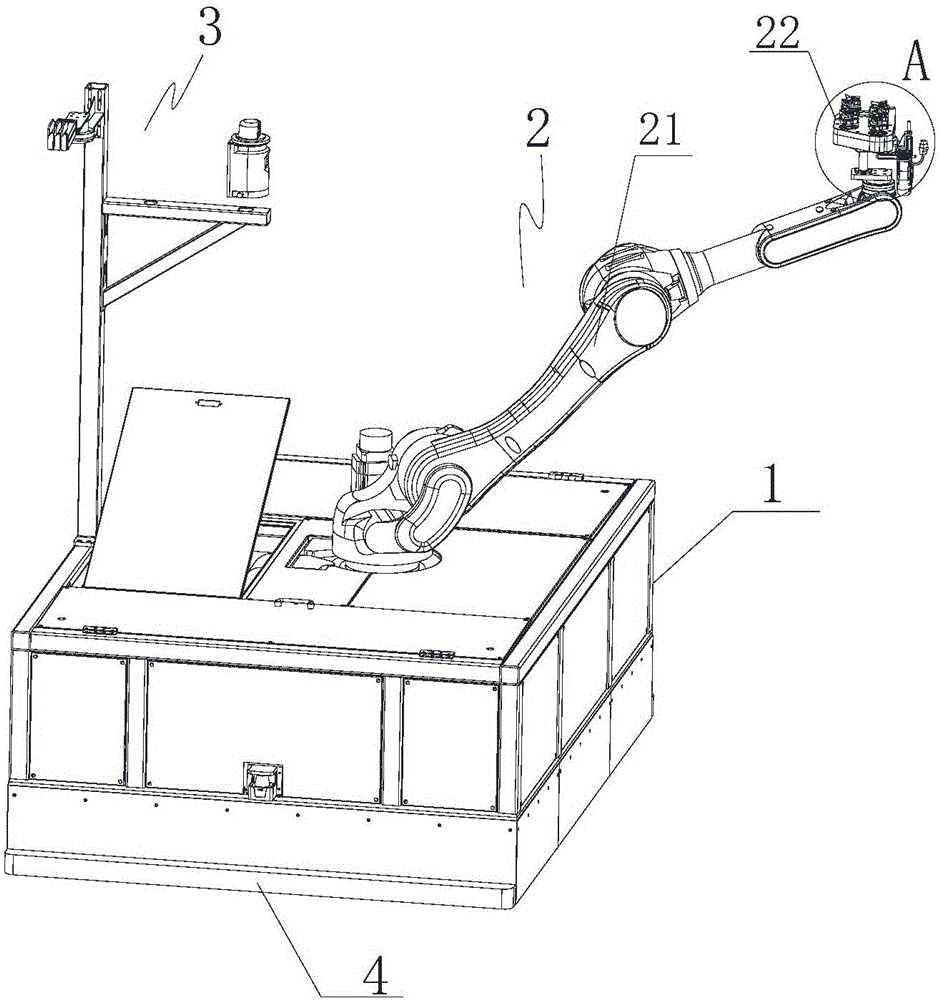

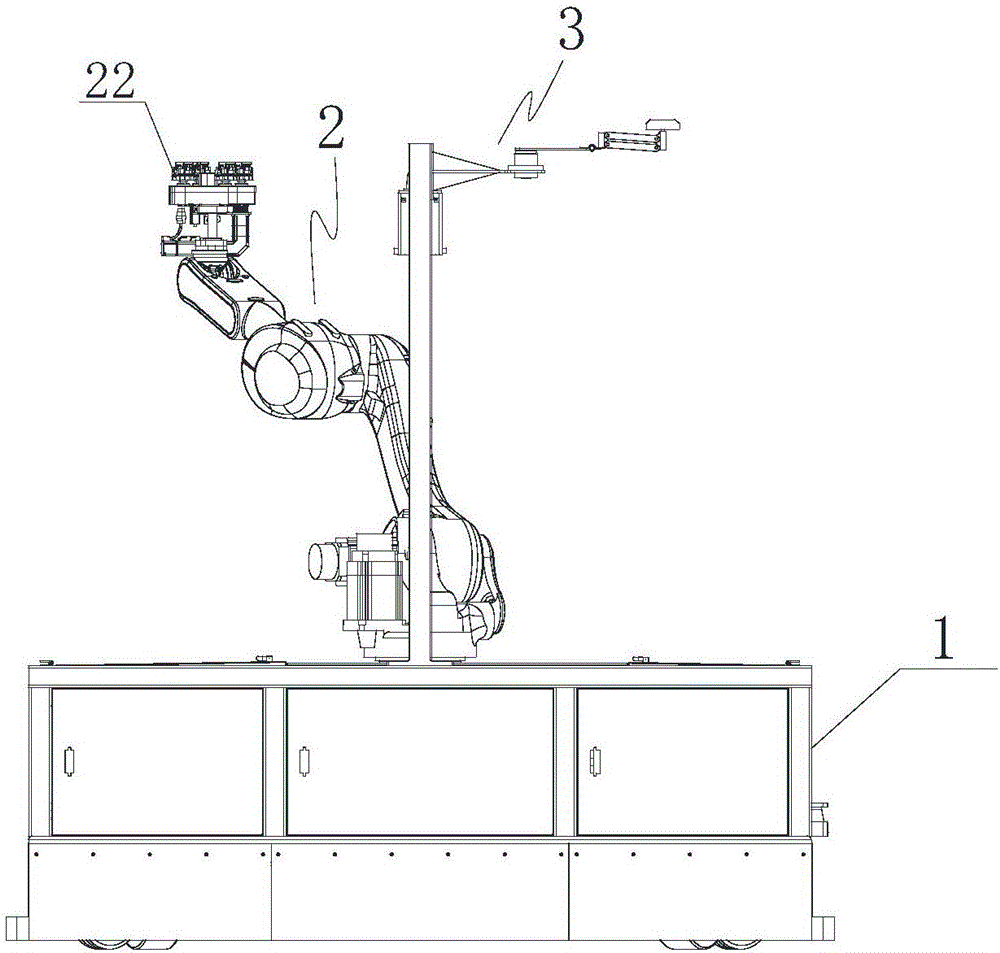

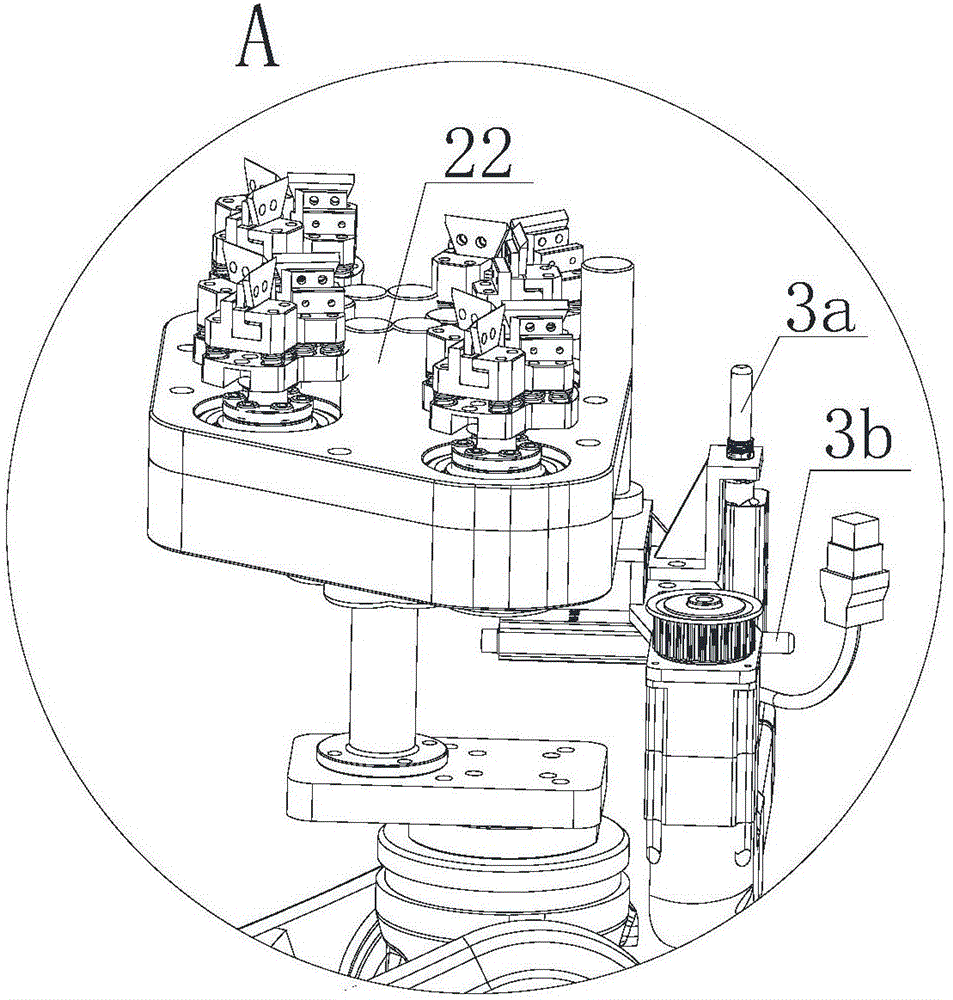

[0039] Such as Figure 1-2 As shown, the automatic board cleaning system of the present invention includes: an AGV trolley 1 and a board cleaning robot 2 arranged on the AGV trolley, the AGV trolley navigates through a laser navigation system 3, and the board cleaning robot 2 includes a multi-joint movable arm 21 and a set In the plate cleaning device 22 at the end of the multi-shutdown movable arm, the plate cleaning device is a device that has several scraper heads and can clean the die heads of the wire drawing die.

[0040] On the multi-joint movable arm 21, at a fixed distance from the plate cleaning device, a positioning probe is provided. The positioning probe includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com