Garden trimmer

A pruning machine and gardening technology, applied to hedge trimming equipment, gardening, gardening tools/equipment, etc., can solve the problems of difficult work, difficult pruning, and insufficient operation, so as to achieve various pruning styles, ensure pruning quality, The effect of low operating intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

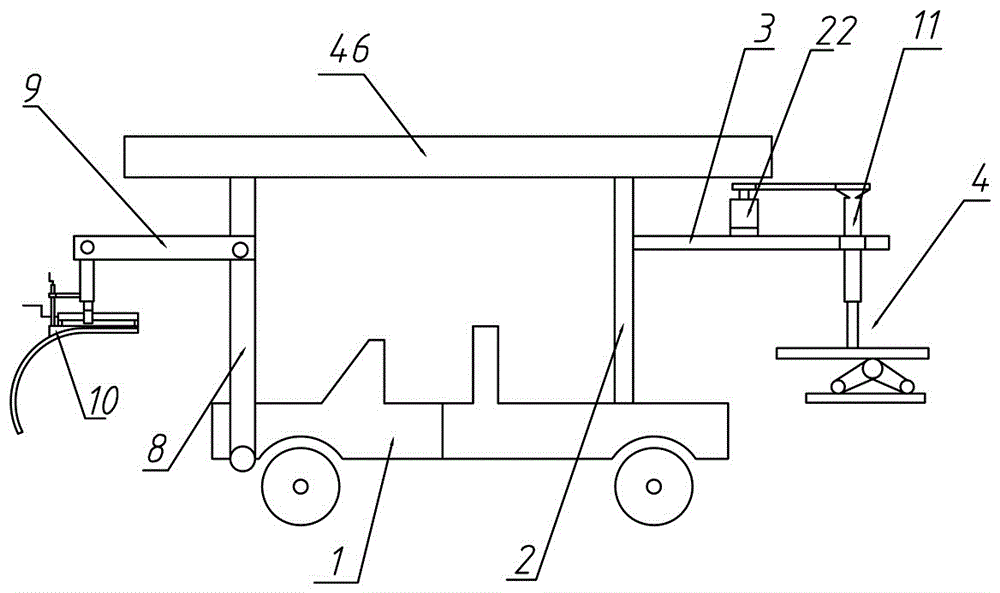

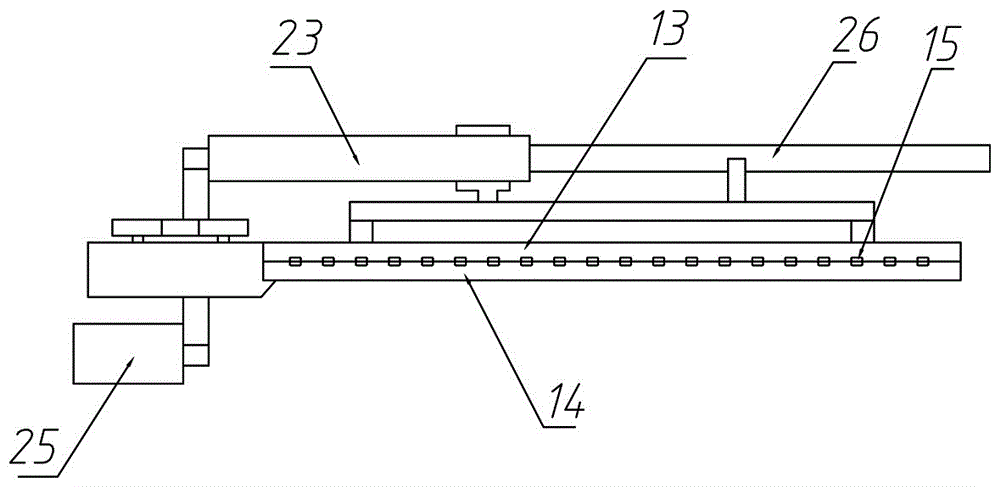

[0048] The garden pruning machine of the present invention comprises a pruning vehicle 1 and a support column 2 arranged on the pruning vehicle 1, wherein the support column 2 is connected with a horizontal pruning device 4 through a horizontal shear fixed arm 3, and the horizontal shear fixed arm 3. One end is movably connected with the supporting column 2, and the other is fixedly connected with the horizontal pruning device 4;

[0049] Described pruning car 1 is also provided with a vertical shear fixed rod 5 and circular arc shear fixed rod 8;

[0050] The vertical shearing fixed rod 5 is connected with a vertical trimming device 7 through the vertical shearing fixed arm 6, one end of the vertical shearing fixed arm 6 is movably connected with the vertical shearing fixed rod 5, and the other end is connected with the vertical trimming device 7 fixed connection;

[0051] Described circular arc shears fixed rod 8 and is connected with an arc pruning device 10 by circular ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com