A solar panel turning device

A technology of solar panels and flipping devices, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of high labor intensity and low work efficiency, and achieve the effect of reducing labor intensity and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

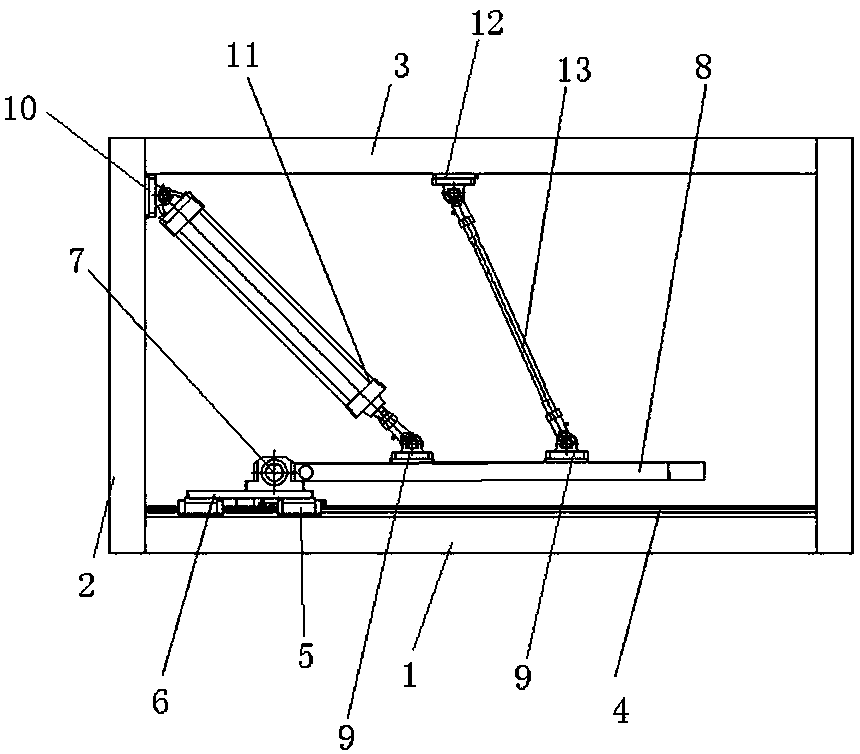

[0008] See figure 1 As shown, a solar cell panel turning device includes a base 1, a side support 2 and an upper support 3, a guide rail 4 is installed on the base 1, and a support 6 is slidably installed on the guide rail 4 through two sliders 5. The seat 6 is equipped with an overturning frame 8 through the rotating shaft 7, the back of the overturning frame 8 is provided with a vacuum suction cup, the front of the overturning frame 8 is provided with two lower hinged seats 9, and the side bracket 2 is provided with an inclined arrangement through the side hinged seats 10. Promote the cylinder 11, the piston rod of the promotion cylinder 11 is hingedly connected to a lower hinged seat 9, the upper support 3 is provided with an upper hinged seat 12, and the upper hinged seat 12 is connected with another lower hinged seat 9 by a connecting rod 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com