Assembly type concrete structure grouting sleeve node acceptance device and using method thereof

A technology for concrete structures and grouting sleeves, which is applied to measuring devices, material analysis using wave/particle radiation, material inspection products, etc., can solve the problems of no special acceptance devices and methods for construction quality, and save manpower and financial resources. The effect of low construction cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

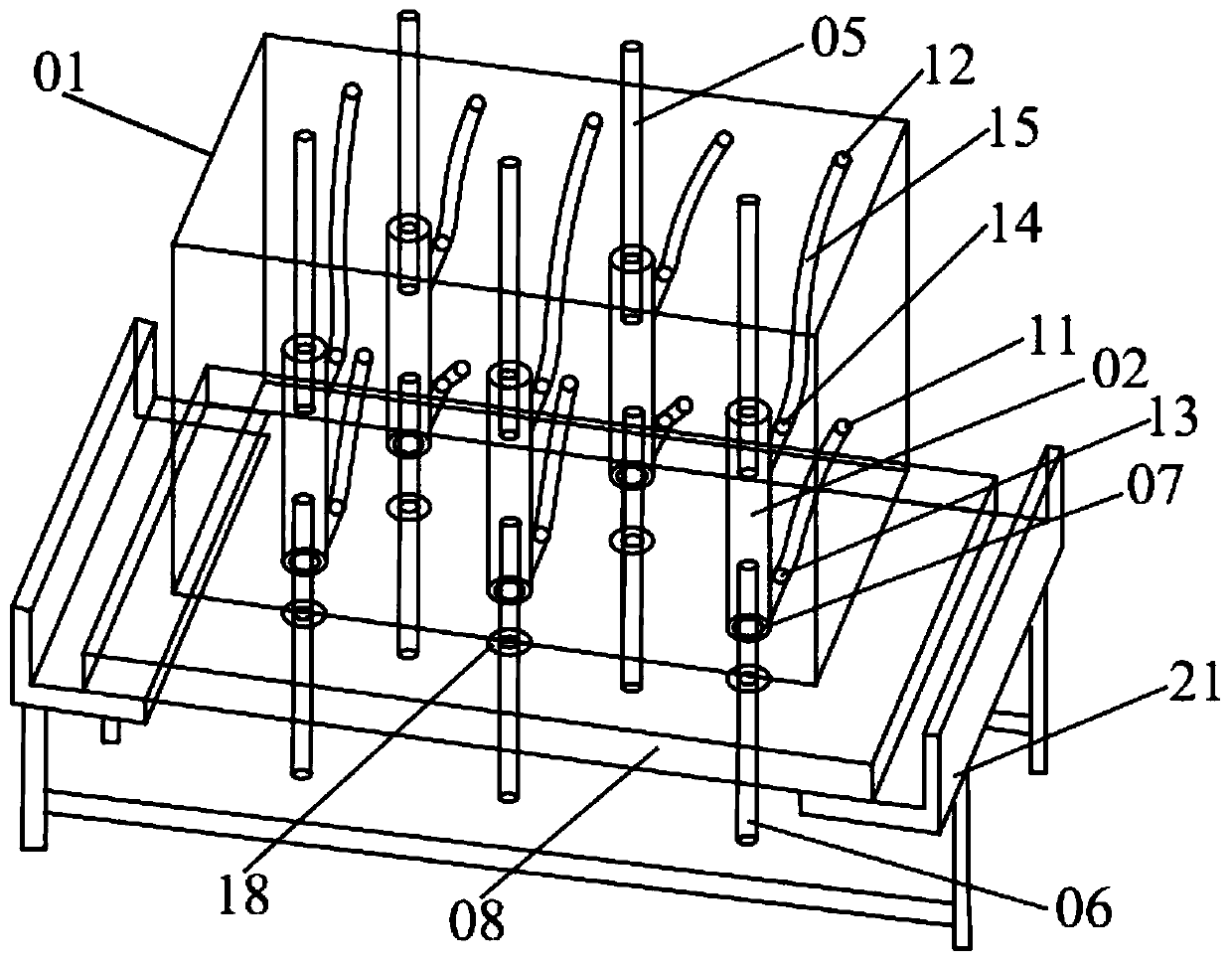

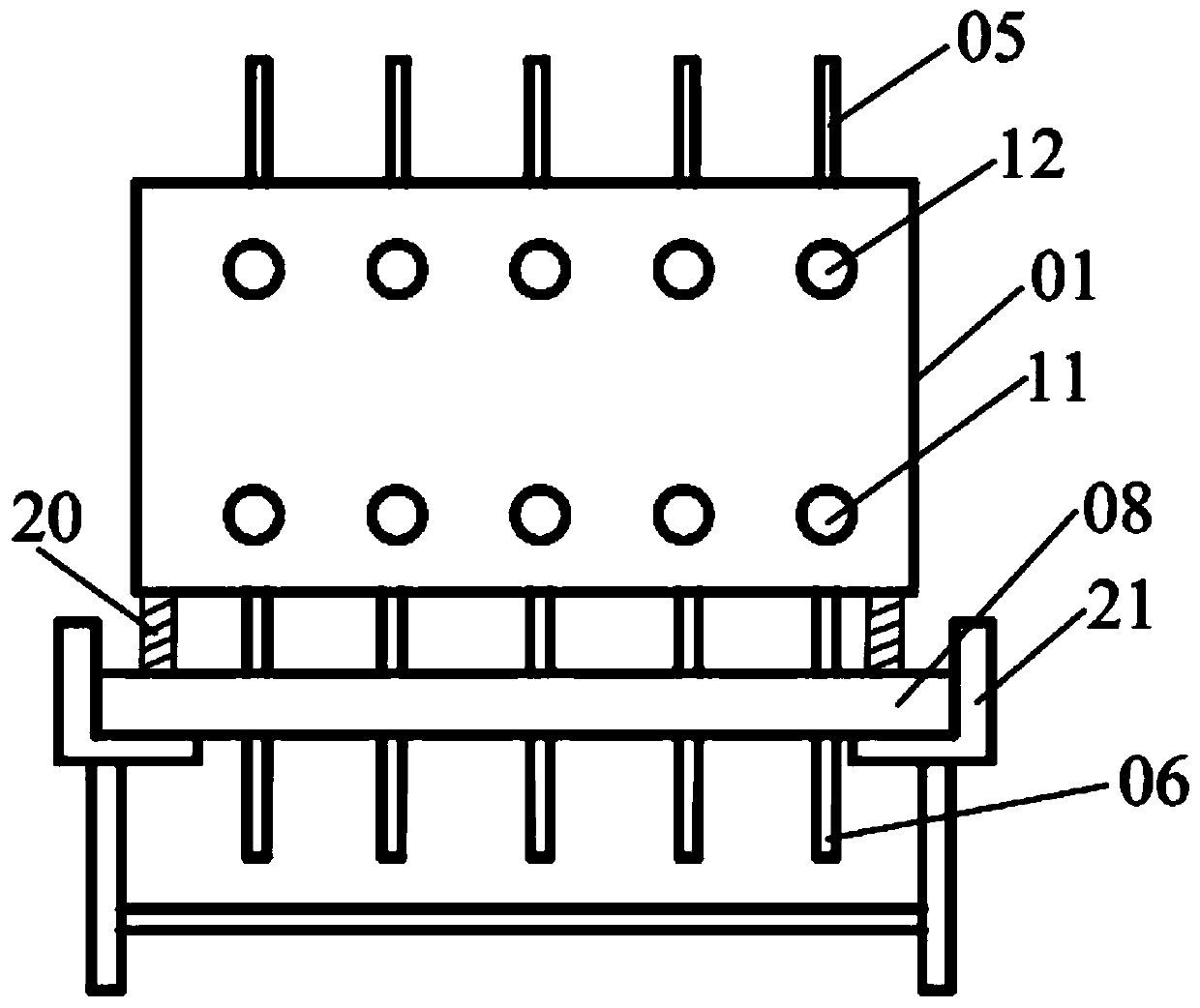

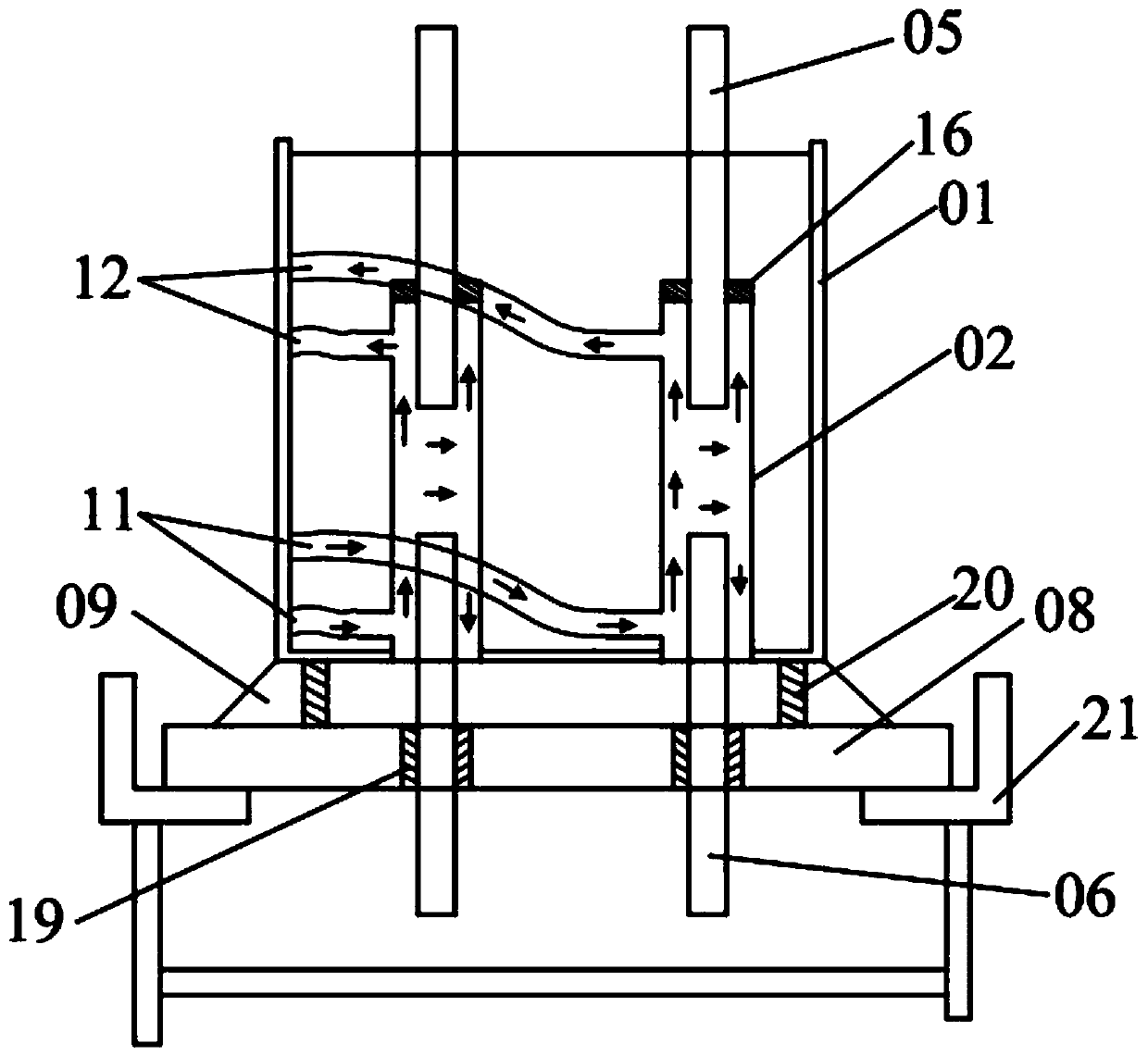

[0029] refer to figure 1 and 2 , the present invention provides a prefabricated concrete structure grouting sleeve node acceptance device, the acceptance device includes: box 01, sleeve 02, steel bars, bottom plate 08 and support frame 21, the upper end of the box 01 is open and the bottom surface is provided with Sleeve fixing hole 07, the upper end of the open box is convenient for placing fine stones, the size of the box 01 is 1200~1500×250×400mm, the bottom surface of the sleeve fixing hole 07 is used to fix the sleeve 02, and it is convenient for the lower steel bar 06 to extend into the sleeve In the cylinder 02, the grouting material can flow into the compartment layer. The sleeve 02 is vertically installed on the sleeve fixing hole 07 inside the box 01. The reinforcement includes the upper reinforcement 05 and the lower reinforcement 06, and the upper reinforcement 05 and the lower reinforcement 06. It represents the stressed steel bar or structural steel bar in the p...

Embodiment 2

[0042] refer to figure 1 and 2 , the present invention provides a prefabricated concrete structure grouting sleeve node acceptance device, the acceptance device includes: box 01, sleeve 02, steel bars, bottom plate 08 and support frame 21, the upper end of the box 01 is open and the bottom surface is provided with Sleeve fixing hole 07, the upper end of the open box is convenient for placing fine stones, the size of the box 01 is 1200~1500×250×400mm, the bottom surface of the sleeve fixing hole 07 is used to fix the sleeve 02, and it is convenient for the lower steel bar 06 to extend into the sleeve In the cylinder 02, the grouting material can flow into the compartment layer. The sleeve 02 is vertically installed on the sleeve fixing hole 07 inside the box 01. The reinforcement includes the upper reinforcement 05 and the lower reinforcement 06, and the upper reinforcement 05 and the lower reinforcement 06. It represents the stressed steel bar or structural steel bar in the p...

Embodiment 3

[0055] This embodiment provides a prefabricated concrete structure grouting sleeve node acceptance device, the structure of which is basically the same as that of Embodiment 1 or 2, the difference being that further improvements are made on the basis of Embodiment 1 or 2.

[0056] refer to Figure 6 , The sleeve 02 provided in this embodiment is a semi-grouting sleeve 04, so that the upper steel bar 05 is fixed with the sleeve 02 through the screw thread, which is more firm. The semi-grouting sleeve 04 includes a grouting port 13, a grouting port 14 and a threaded end 17, the grouting port 13 and the grouting port 14 are respectively arranged at the two ends of the same side of the sleeve 02, the grouting port 13 and the grouting port 14 They are respectively connected to the grouting hole 11 and the grouting hole 12 through the grouting pipe 15. The threaded end 17 is the end of the sleeve 02 body close to the grouting port 14. The central inner wall of the threaded end 17 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com