Single-phase magnetic latching operating mechanism

A technology of operating mechanism and magnetic retention, applied in the direction of the power device inside the switch, etc., can solve the problems of mechanism failure, NdFeB demagnetization, unfavorable high and low voltage circuit control, etc., and achieve the effect of avoiding failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

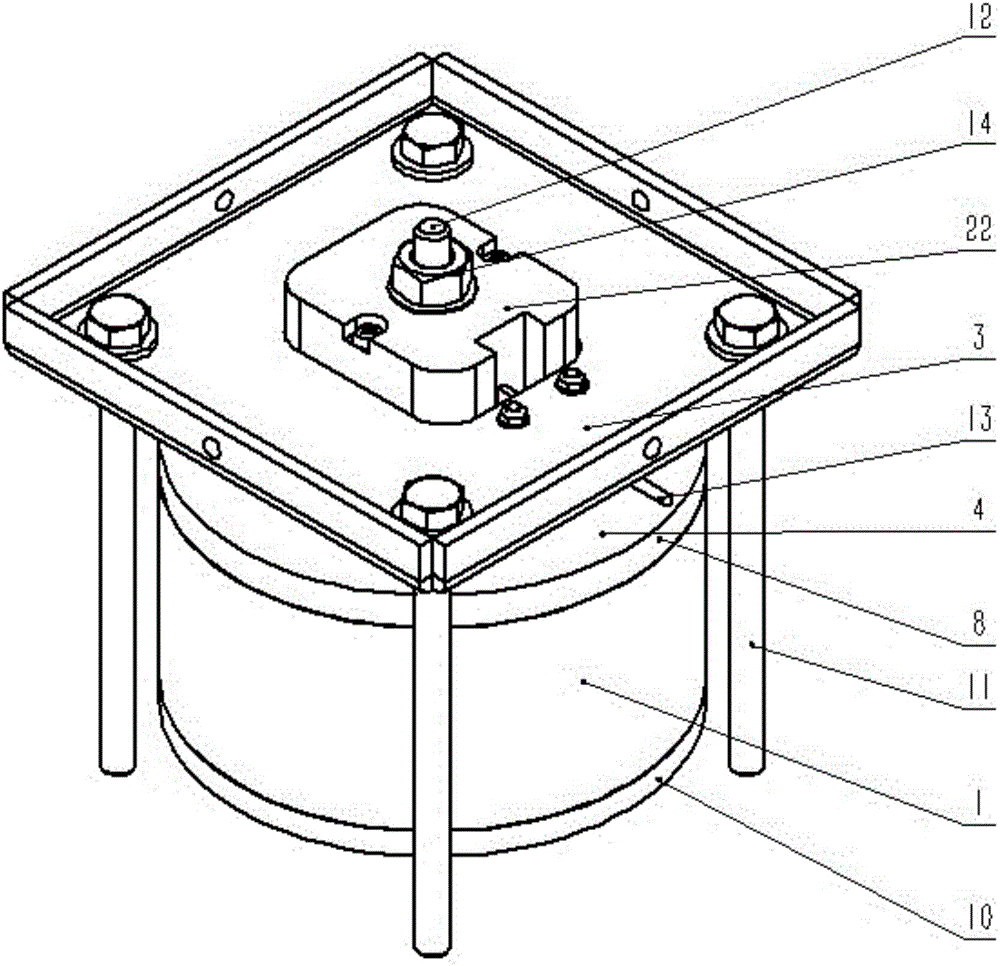

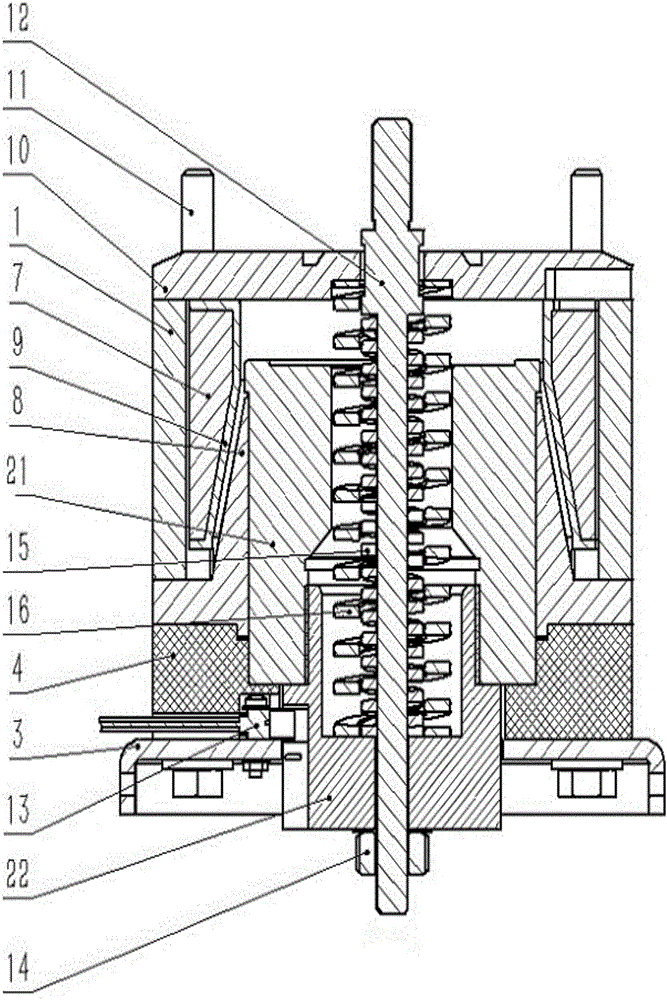

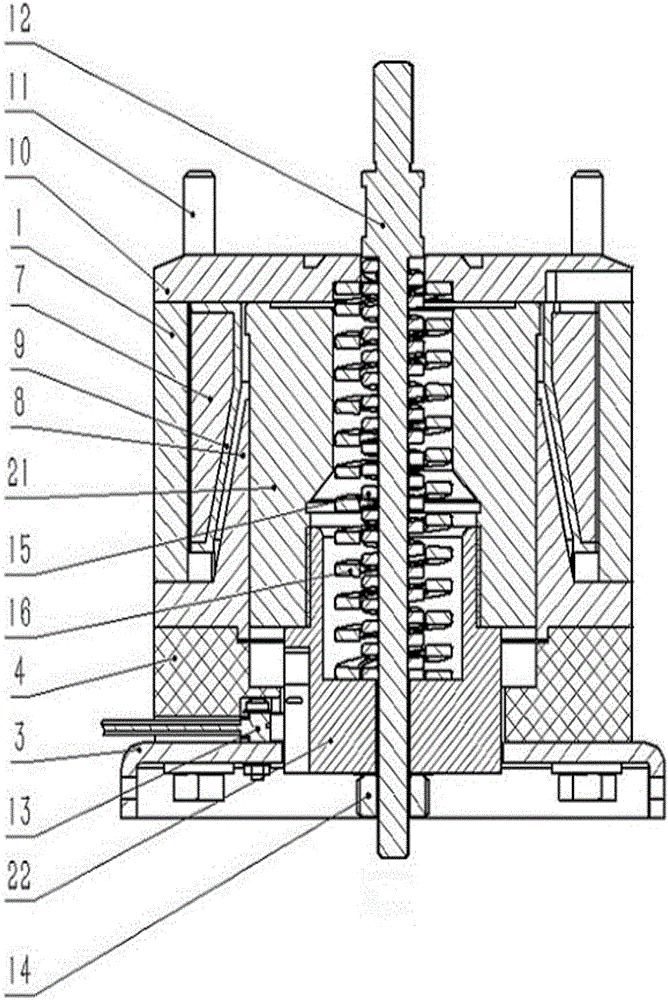

[0035] Such as Figure 1-3 As shown, in a specific embodiment, the single-phase magnetic holding operation mechanism of the present invention includes: an upper yoke 10, a magnetic sleeve 1, a lower yoke 8, a lower plastic end block 4, a coil 7, a moving iron core 21, Plastic cover 22, pull rod 12, opening spring 16 and closing pressure spring 15.

[0036] Such as Figure 2-3 As shown, the upper yoke 10, the magnetic sleeve 1 and the lower yoke 8 are arranged sequentially from top to bottom, and jointly enclose a magnetic field space; the coil 7 and the moving iron core 21 are respectively arranged in the magnetic field space; the lower plastic end The block 4 is fitted under the lower yoke 8, and the moving iron core 21 assembly is limited in the magnetic field space; one end of the plastic cover 22 is screwed to the moving iron core 21, and the other end extends away from the magnetic field space Lower plastic end block 4;

[0037] One end of the pull rod 12 passes throug...

Embodiment 2

[0042] Such as Figure 1-3As shown, in a specific embodiment, the present invention provides a single-phase magnetic holding operation mechanism, including an upper yoke 10, a lower yoke 8, a magnetic sleeve 1, a moving iron core assembly 2, and a lower plastic end block 4 and a metal fixed platen 3, a coil 7 is arranged between the upper yoke 10, the lower yoke 8 and the magnetic sleeve 1, and the moving iron core assembly 2 includes a moving iron core 21 and a plastic cover installed with threads on its lower part 22. The moving iron core 21 passes through the operation pull rod 12, the opening spring 16 and the closing pressure spring 15 in the middle, and the photoelectric sensing element 13 is embedded in the lower plastic end block 4, and the signal line of the photoelectric sensing element passes through the metal The groove between the fixed pressure plate 3 and the lower plastic end block 4 is drawn out, and the metal fixed pressure plate 3 is fixed and pressed to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com