A kind of three-dimensional graphene-based nitrogen-doped porous carbon composite electrode material and preparation method thereof

A composite electrode and alkenyl nitrogen technology, applied in the field of materials science, can solve the problems of weakening electrochemical activity and hindering electron transfer, so as to achieve the effect of highlighting the cycle ability and shortening the transportation path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

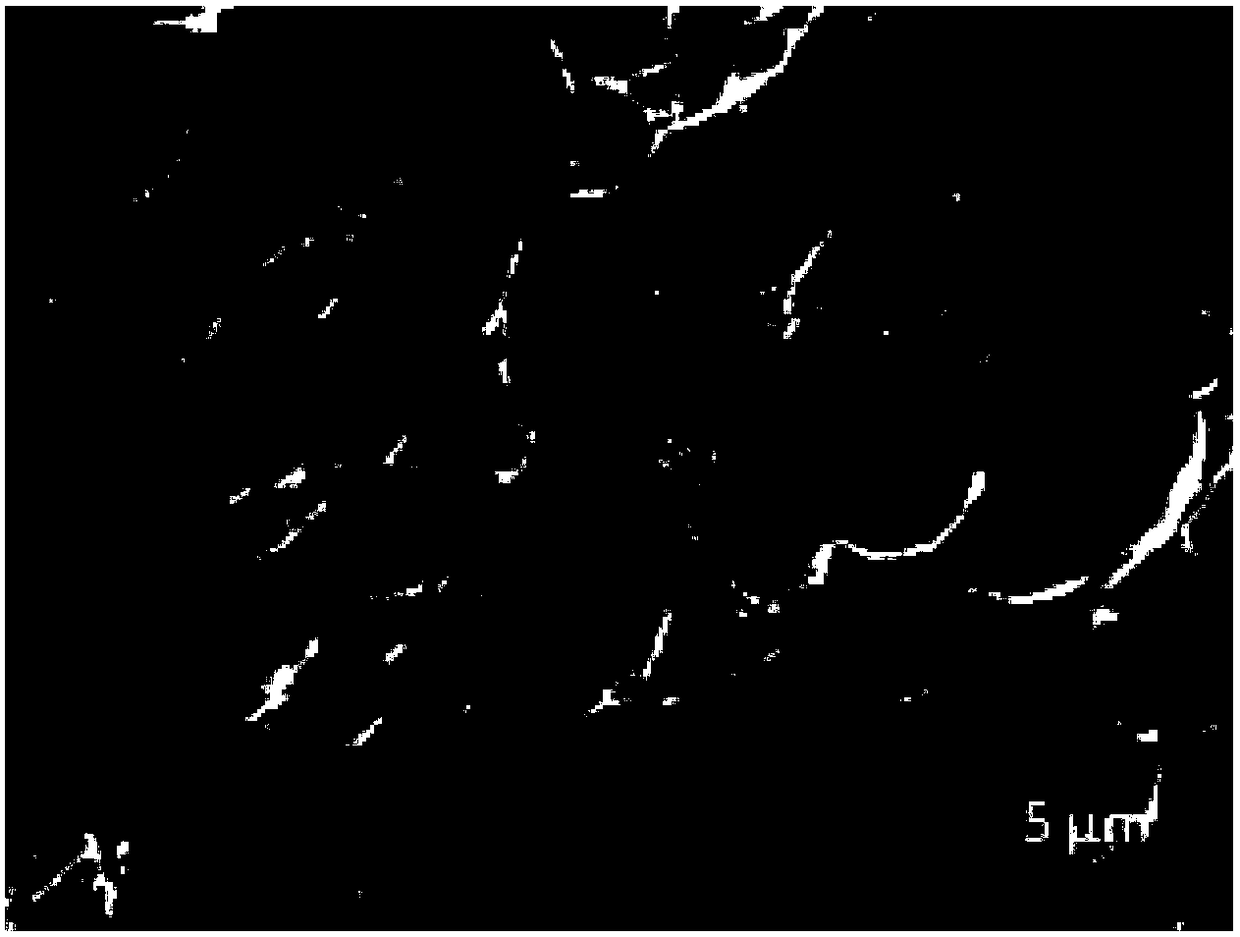

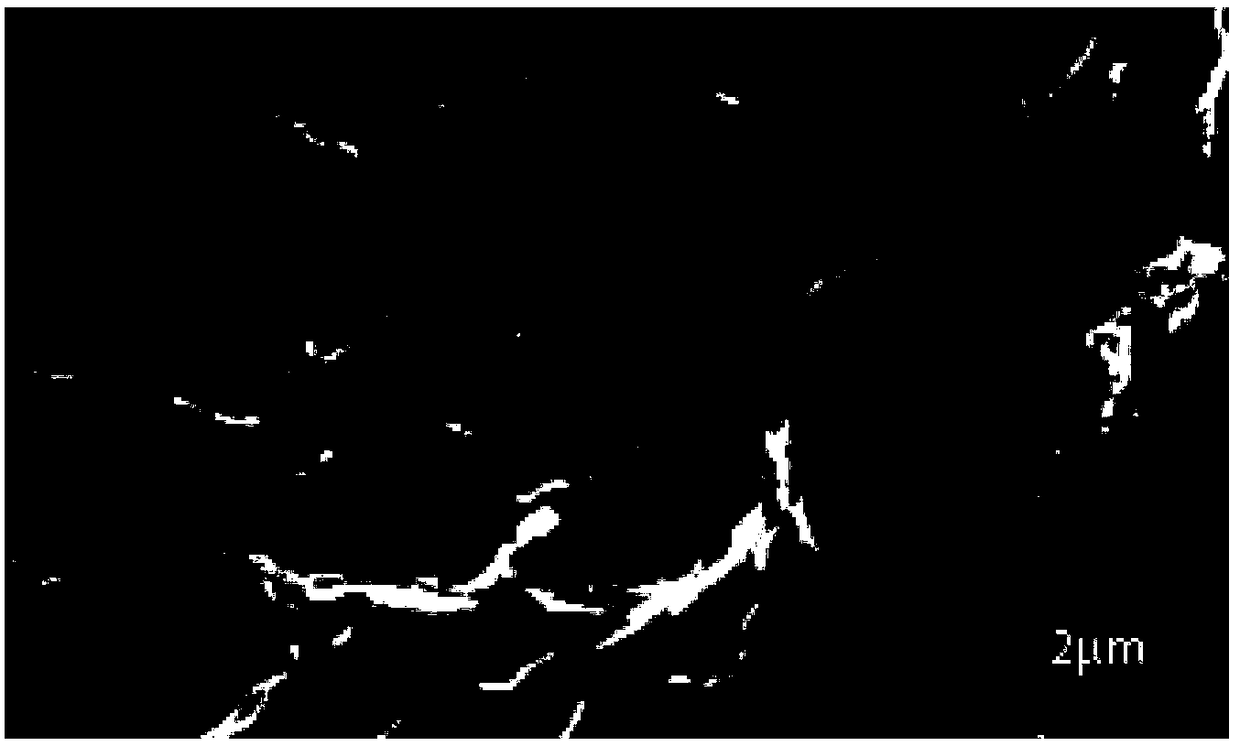

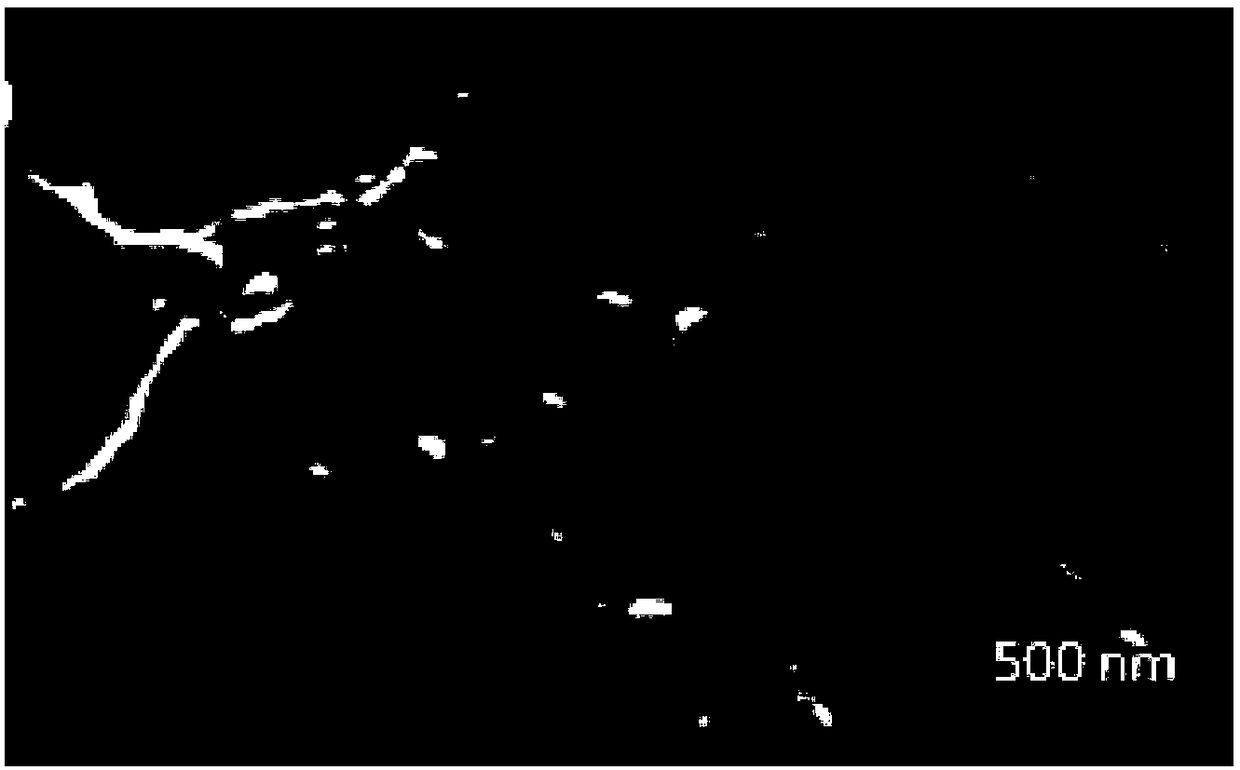

Image

Examples

Embodiment 1

[0030] A preparation method of an NPC-GAs three-dimensional hierarchical structure electrode material, comprising the steps of:

[0031] (1) Graphene oxide (GO) was prepared by the modified Hummers method, and the synthesis steps included pre-oxidation and secondary oxidation.

[0032] (2) Preparation of graphene airgel (GAs):

[0033] a. Take 0.6g of polyoxyethylene polyoxypropylene block copolymer (F-127) in a 100mL beaker, add 20mL of deionized water, and sonicate for 3h until F-127 (400mg) is completely dissolved;

[0034] b. Add 100mg of graphene to the 100mL beaker in step a, add deionized water to 50mL and stir evenly;

[0035] c. Transfer the above solution to a 100mL hydrothermal kettle, carry out hydrothermal reaction, and react at 175°C for 16h;

[0036] d. The block solid sample obtained is put into a glass cup and put into a freeze dryer for vacuum drying;

[0037] e. Take out the dried sample, put it into a nitrogen furnace for burning, protect the whole proce...

Embodiment 2

[0045] A preparation method of an NPC-GAs three-dimensional hierarchical structure electrode material, comprising the steps of:

[0046] (1) Graphene oxide (GO) was prepared by the modified Hummers method, and the synthesis steps included pre-oxidation and secondary oxidation.

[0047] (2) Preparation of graphene airgel (GAs):

[0048] a. Take 0.6g F-127 in a 100mL beaker, add 20mL deionized water, and sonicate for 3h until F-127 (500mg) is completely dissolved;

[0049]b. Add 100mg of graphene to the 100mL beaker in step a, add deionized water to 50mL and stir evenly;

[0050] c. Transfer the above solution to a 100mL hydrothermal kettle, carry out hydrothermal reaction, and react at 180°C for 17h;

[0051] d. The block solid sample obtained is put into a glass cup and put into a freeze dryer for vacuum drying;

[0052] e. Take out the dried sample, put it into a nitrogen furnace for burning, protect the whole process with nitrogen, raise the temperature to 680°C at a rate...

Embodiment 3

[0060] A preparation method of an NPC-GAs three-dimensional hierarchical structure electrode material, comprising the steps of:

[0061] (1) Graphene oxide (GO) was prepared by the modified Hummers method, and the synthesis steps included pre-oxidation and secondary oxidation.

[0062] (2) Preparation of graphene airgel (GAs):

[0063] a. Take 0.6g F-127 in a 100mL beaker, add 20mL deionized water, and sonicate for 3h until F-127 (500mg) is completely dissolved;

[0064] b. Add 100mg of graphene to the 100mL beaker in step a, add deionized water to 50mL and stir evenly;

[0065] c. Transfer the above solution to a 100mL hydrothermal kettle, carry out hydrothermal reaction, and react at 180°C for 18h;

[0066] d. The block solid sample obtained is put into a glass cup and put into a freeze dryer for vacuum drying;

[0067] e. Take out the dried sample, put it into a nitrogen furnace for burning, protect the whole process with nitrogen, raise the temperature to 700°C at a rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com