Electrically-controlled dimming device

An electronically controlled adjustment and device technology, applied in the field of dimming, can solve problems such as poor effect and complicated process, and achieve the effect of simple structure, high transmittance, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

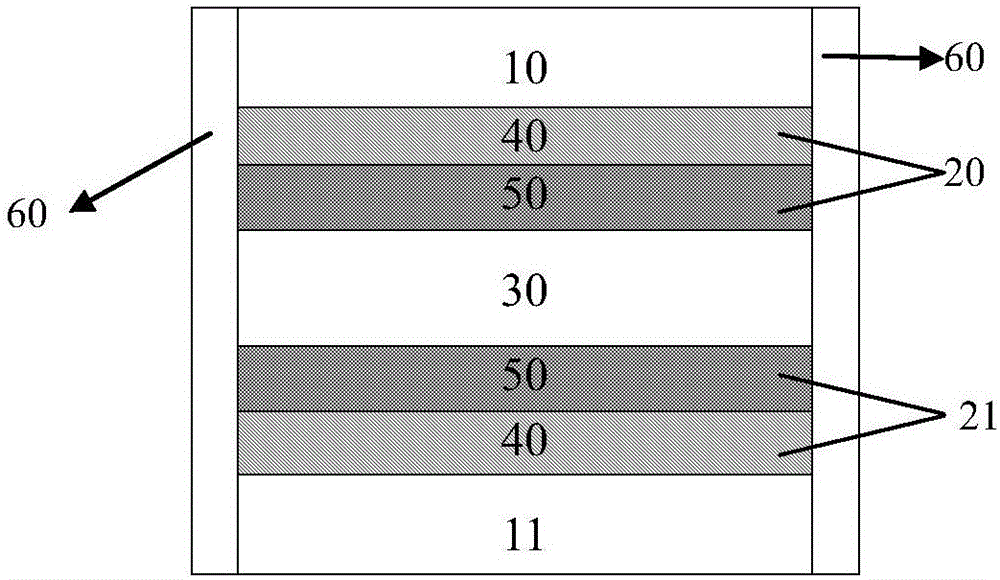

[0041] Such as figure 1 As shown, the present invention provides a reverse electronically controlled dimming device, including an upper transparent substrate 10, a first functional layer 20, an electrically controllable optical refractive index layer 30, and a second functional layer arranged sequentially from top to bottom. Layer 21, lower transparent substrate 11. The conductive layer 40 in the first functional layer 20 is arranged on the surface of the upper transparent substrate, and the microstructure layer 50 is arranged on the surface of the conductive layer; the conductive layer 40 in the second functional layer 21 is arranged on the surface of the lower transparent substrate, and the microstructure layer 50 is arranged on the surface of the transparent substrate. Layer 50 is sequentially disposed on the surface of the conductive layer. Wherein, the material of the layer capable of electrically controlling and adjusting the light refractive index is liquid crystal, a...

Embodiment 2

[0044] Such as figure 1 As shown, the present invention provides a formal electronically controlled dimming device, including an upper transparent substrate 10, a first functional layer 20, an electrically controllable optical refractive index layer 30, and a second functional layer arranged sequentially from top to bottom. 21. The lower transparent substrate 11. The conductive layer 40 in the first functional layer 20 is arranged on the surface of the upper transparent substrate, and the microstructure layer 50 is arranged on the surface of the conductive layer; the conductive layer 40 in the second functional layer 21 is arranged on the surface of the lower transparent substrate, and the microstructure layer 50 is arranged on the surface of the transparent substrate. Layer 50 is sequentially disposed on the surface of the conductive layer. Wherein, the material of the layer capable of electrically controlling and adjusting the light refractive index is liquid crystal, and ...

Embodiment 3

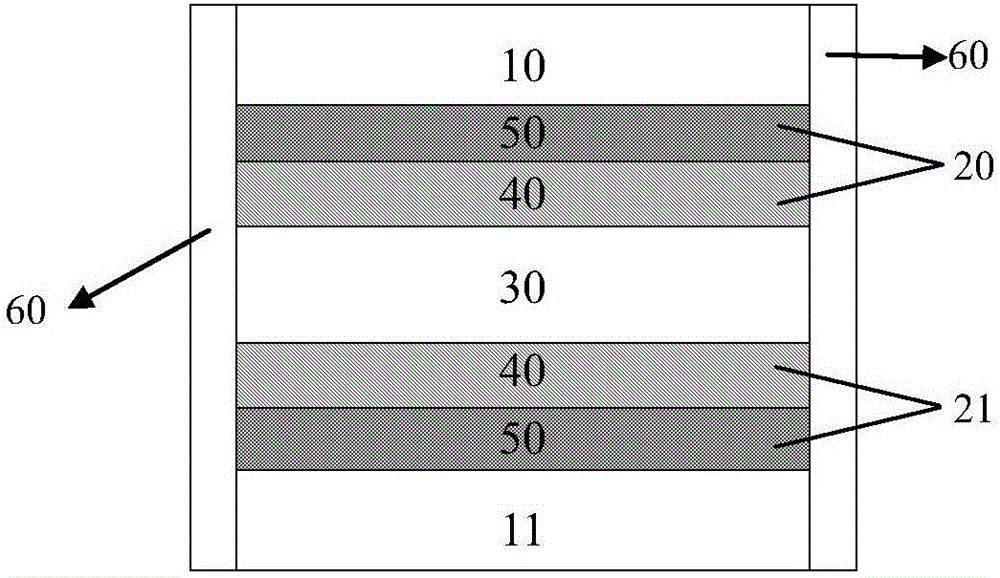

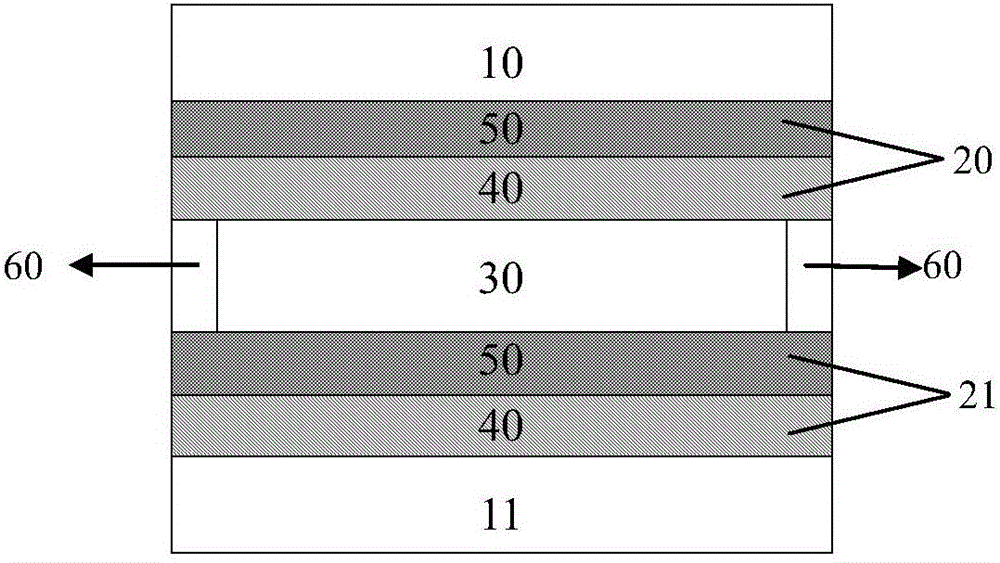

[0047] Such as figure 2 As shown, the present invention provides a reverse electronically controlled dimming device, including an upper transparent substrate 10, a first functional layer 20, an electrically controllable optical refractive index layer 30, and a second functional layer arranged sequentially from top to bottom. Layer 21, lower transparent substrate 11. The microstructure layer 50 in the first functional layer 20 is arranged on the surface of the upper transparent substrate, and the conductive layer 40 is arranged on the surface of the microstructure layer; the microstructure layer 50 in the second functional layer 21 is arranged on the surface of the lower transparent substrate, The conductive layer 40 is sequentially disposed on the surface of the microstructure layer. The liquid crystal is poured between the first functional layer 20 and the second functional layer 30 , and the two sides of the electronically controlled dimming device are sealed with a frame ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com