High voltage electric energy meter remote on-line verification system

A technology for high-voltage electric energy and electric energy meters, which is applied in the field of remote online calibration, can solve the problems of low equipment utilization, difficulty in operation and maintenance of metering devices, and low work efficiency, so as to reduce installation economic costs, improve equipment utilization, reduce The effect of human cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

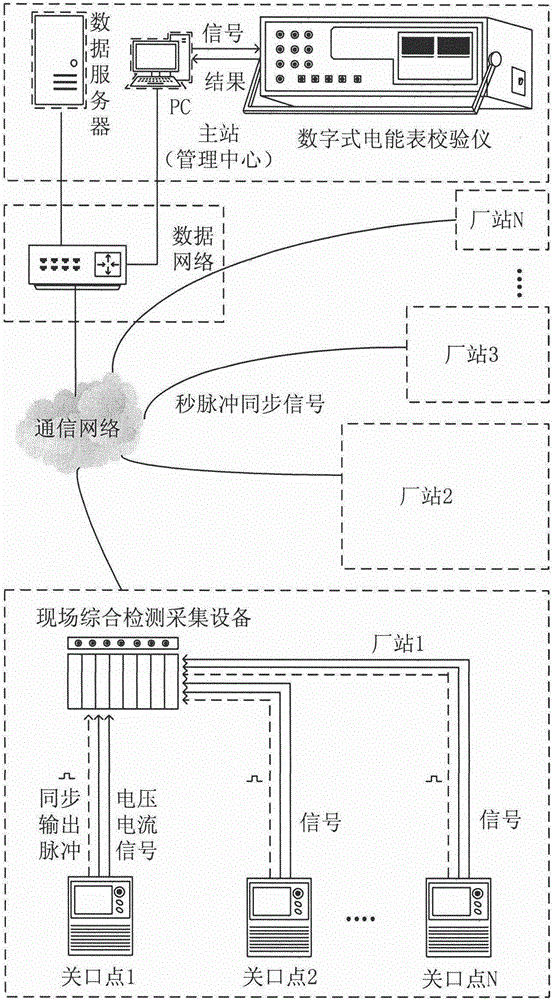

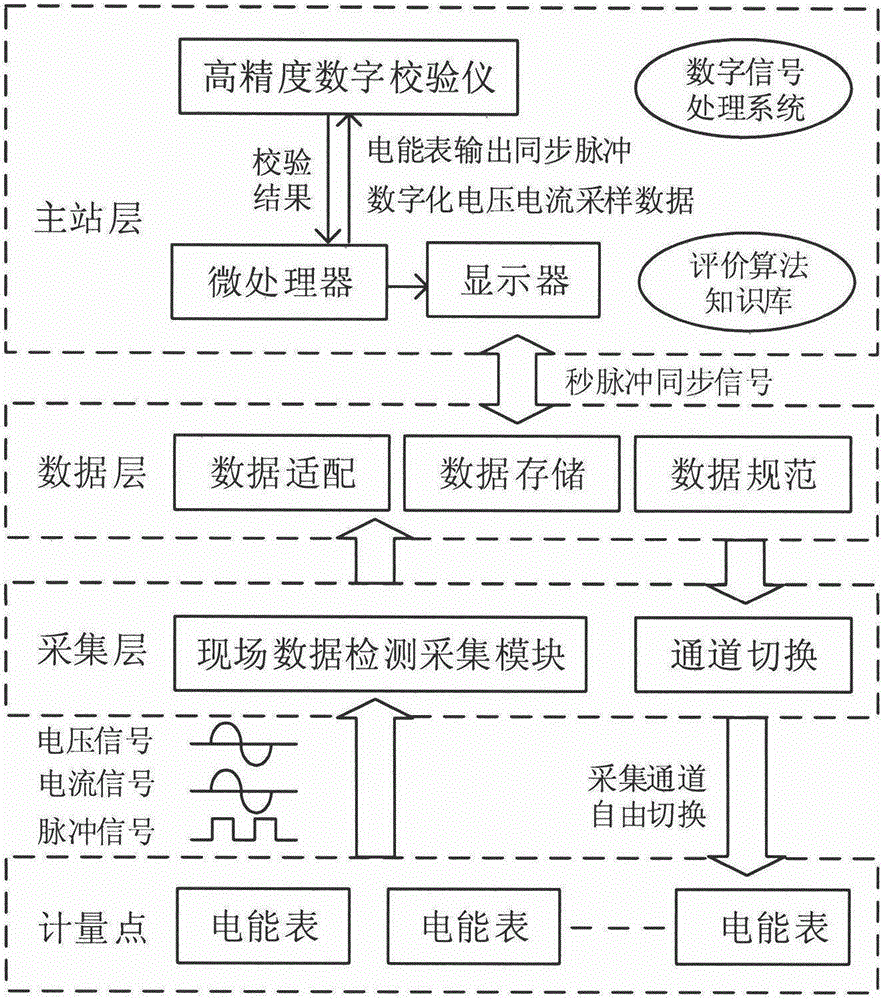

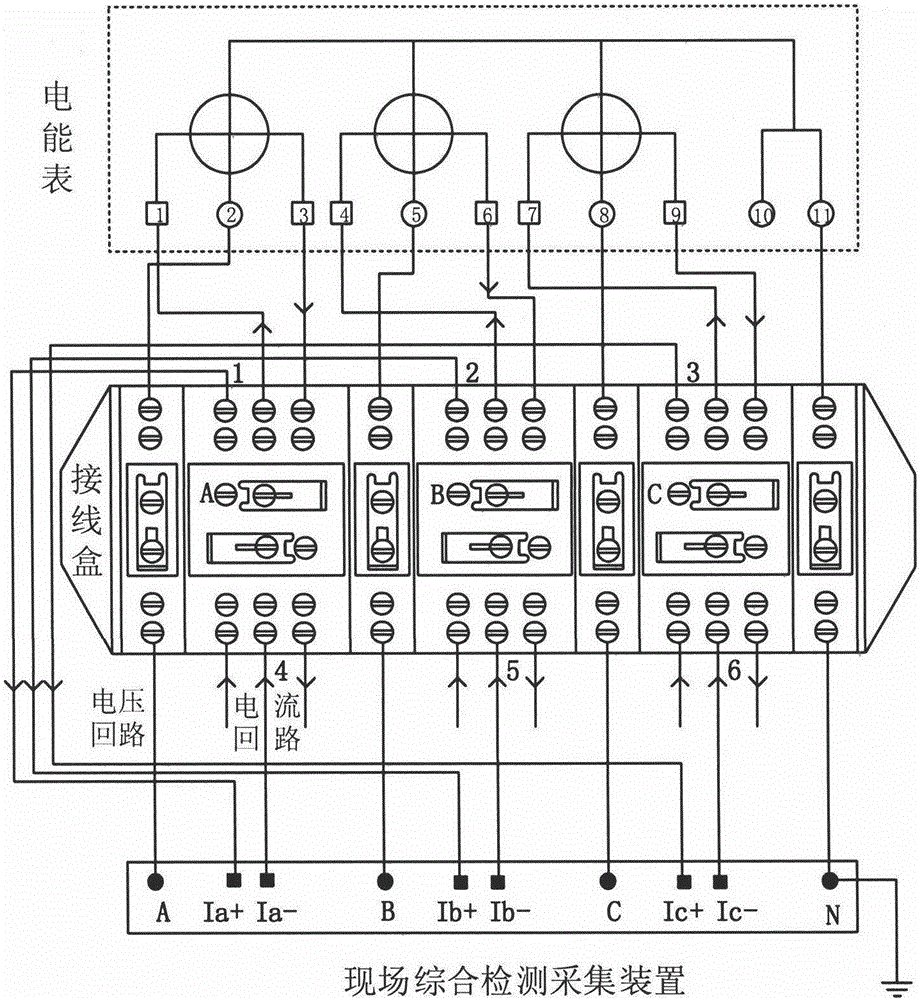

[0021] The remote verification method of the high-voltage electric energy meter of the present invention is based on the current electricity consumption information collection system, and is composed of on-site comprehensive detection and collection equipment, a communication network, a data network, and a laboratory master station system. The on-site comprehensive detection and collection equipment is installed in the metering cabinets of each factory station, which can replace the existing data collection terminal. The laboratory master station collects the data of the on-site comprehensive detection and collection equipment through the communication network, and these data and information are centrally stored in the server. In the database, the real-time accuracy information of a specific energy meter can be obtained after calculation and analysis. The laboratory mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com