Particle dispersion device based on negative pressure adsorption

A technology of dispersing device and particles, applied in particle and sedimentation analysis, measuring device, particle size analysis and other directions, can solve the problems of unstable particle dispersing device and poor effect, and achieve real and reliable results, simple device structure and good device effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific implementation plan

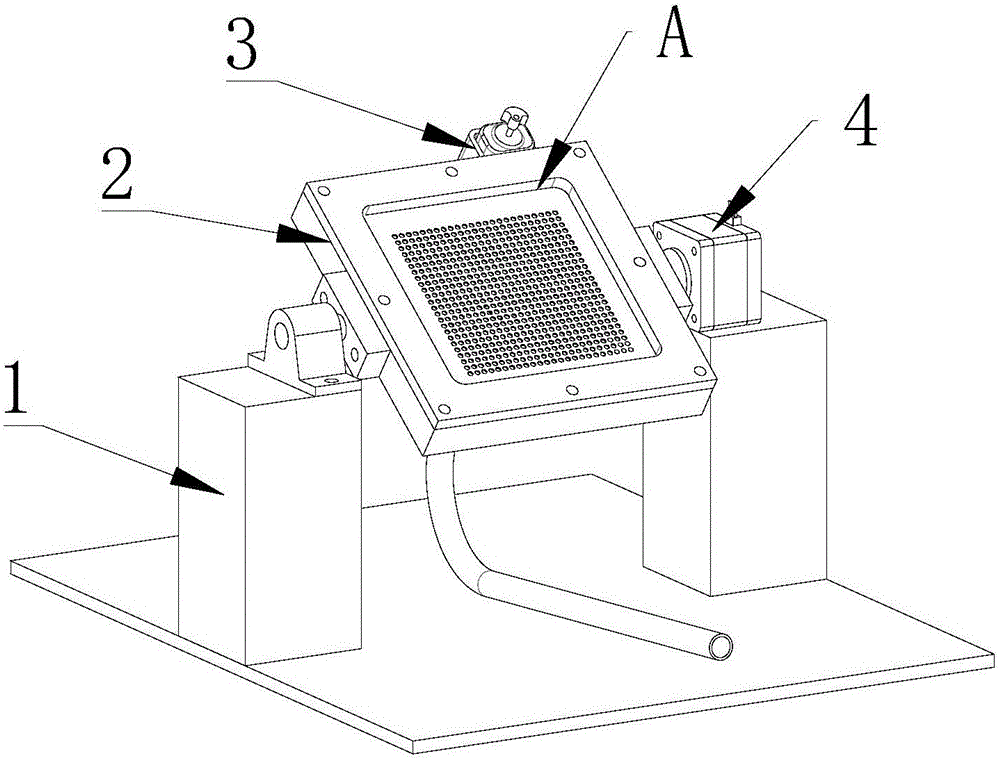

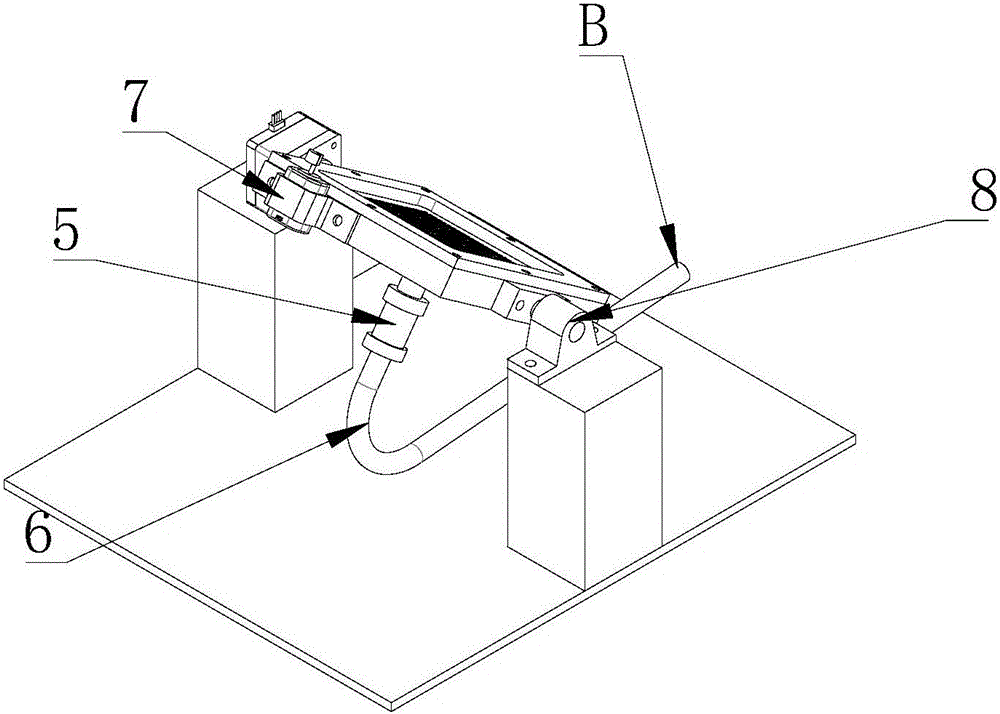

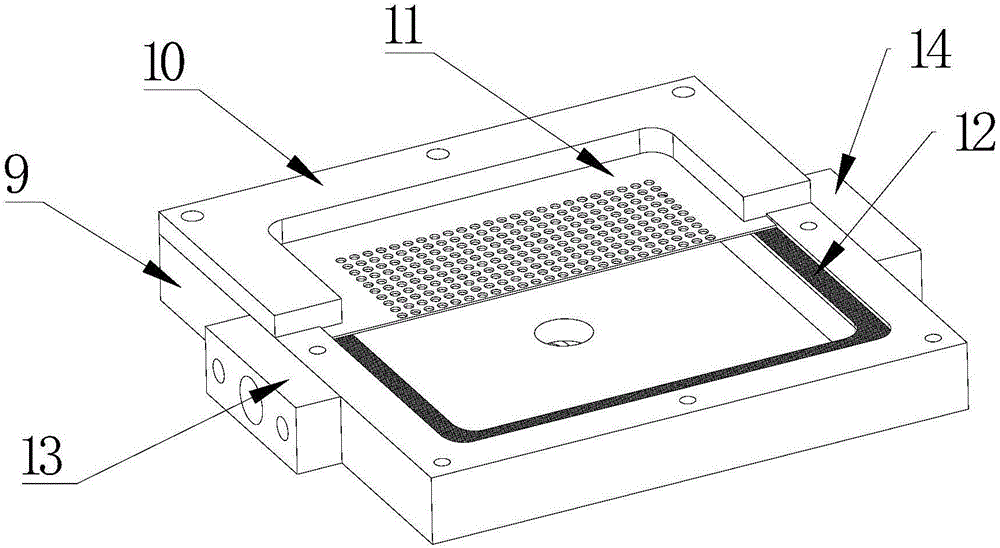

[0015] Such as figure 1 , 2 Shown. The particle dispersion device based on negative pressure adsorption includes a base 1, a screening mechanism 2, a vibrating motor 3, a stepping motor 4, a dust filter 5, a hose 6, a motor fixed bending plate 7, and a shaft seat 8. The base 1 is placed flat on the worktable, and the screening mechanism and the base are connected through the shaft base 8 and the extended shaft of the stepping motor 4, and can rotate freely under the driving of the stepping motor 4. The vibration motor 3 is connected to the screening mechanism 2 by bolts through the motor fixed bent plate 7, and the end of the vibration motor shaft is connected with a centrifugal block, which can generate high frequency vibration. The dust filter 5 is connected with the back of the screening mechanism through an airtight thread to prevent the dust in the screening mechanism 2 from entering the hose 6. The hose 6 and the dust filter 5 are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com